SiC material comprising combination of alpha-SiC and beta-SiC and two-part plasma chamber cathode manufactured using the same

A plasma chamber and combined type technology, which is applied in the field of α-SiC-β-SiC combined reaction sintered SiC material and its preparation and two-body plasma chamber cathode using the material, which can solve the problem of increasing cathode manufacturing costs and increasing silicon carbide The content of impurities in the sintered body, it is difficult to apply to wafer engineering and other issues, to achieve the effect of improving the preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

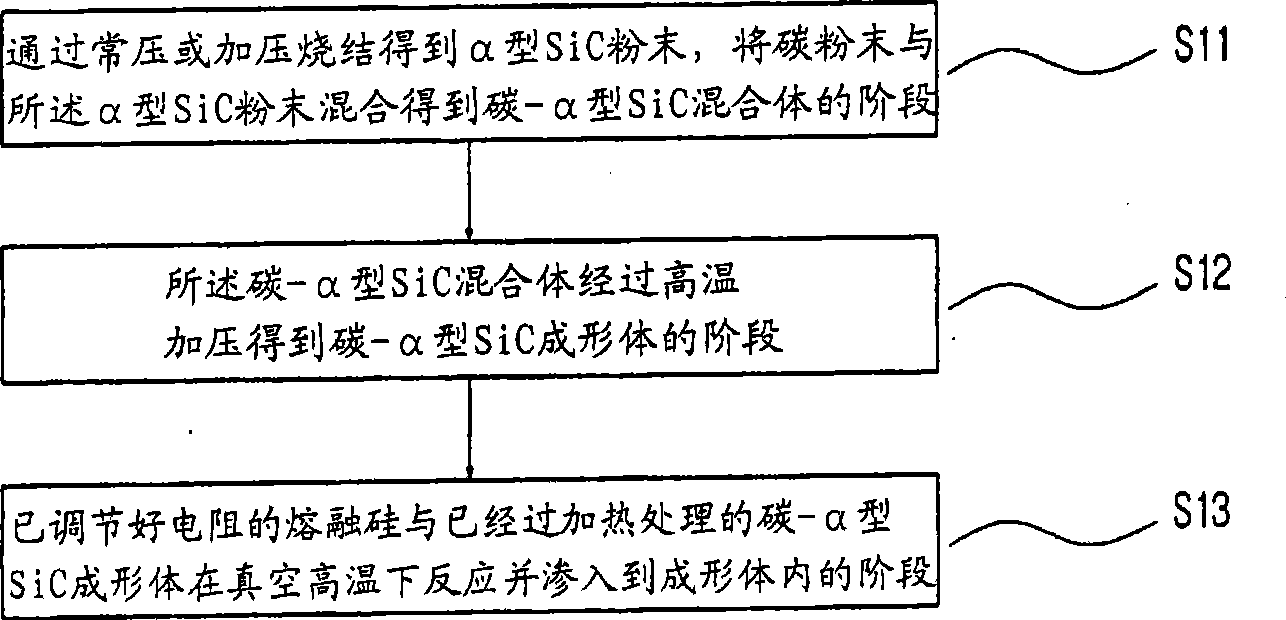

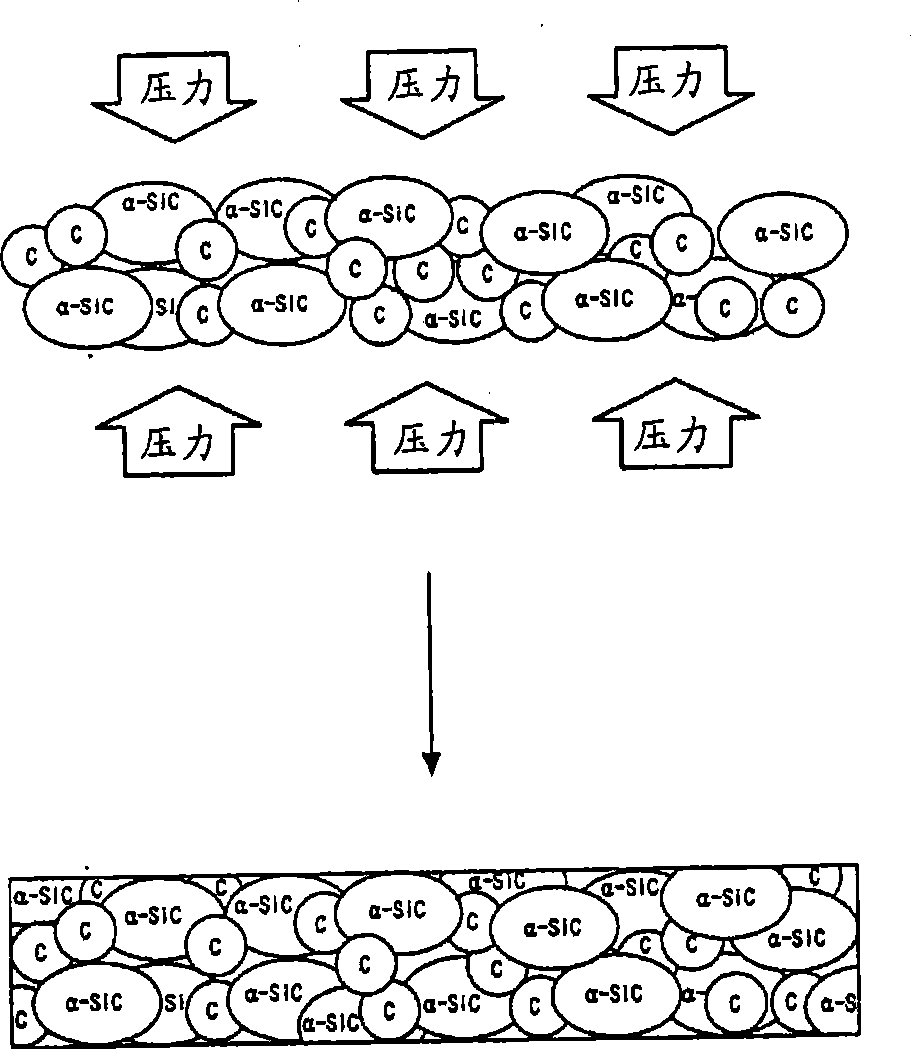

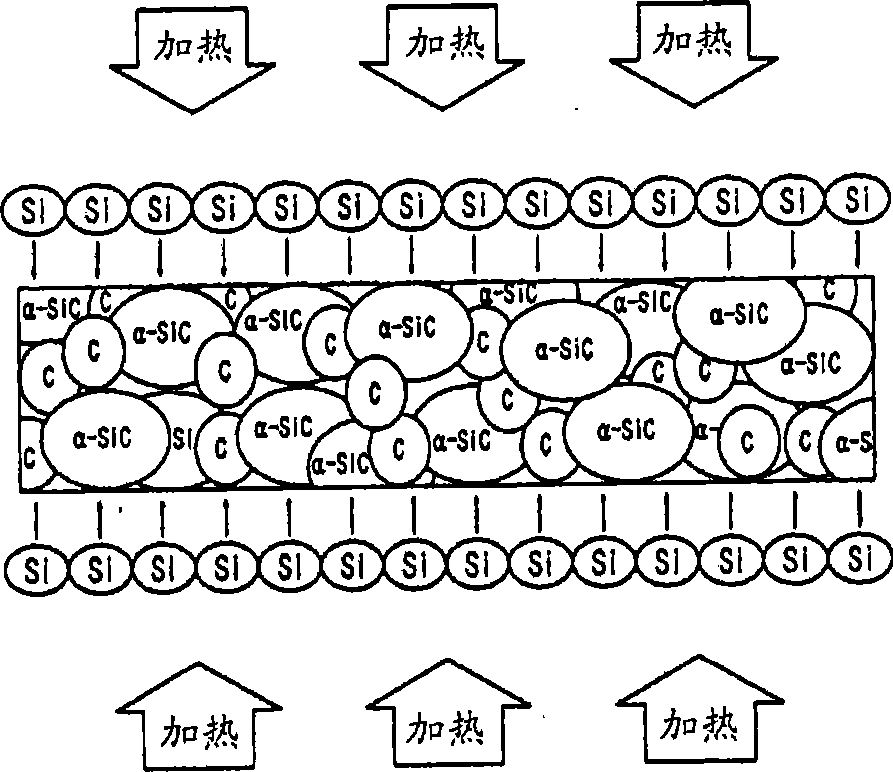

[0026] The present invention relates to a preparation method of SiC material widely used in semiconductor manufacturing engineering components under high temperature and high pressure environment in recent years and a two-body plasma chamber cathode using the SiC material, wherein the two-body plasma chamber cathode is A two-body plasma chamber cathode with a silicon-SiC structure, a flat or an angled outer funnel shape, and a drop. According to one aspect of the present invention, as a method for preparing a SiC sintered body material, a method for preparing an α-SiC-β-SiC combination type reaction sintered SiC material is provided, which specifically includes the following stages. The α-SiC powder is obtained by sintering under normal pressure or pressure, and the carbon powder is mixed with the α-SiC powder to obtain a carbon-α-SiC mixture; the carbon-α-SiC mixture is subjected to high-temperature pressurization, The stage of obtaining the carbon-α-type SiC molded body; und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com