Low temperature multiple-effect seawater last effect evaporator and working method thereof

A condenser and seawater technology, which is applied in the field of low-temperature multi-effect seawater desalination final-effect condensers, can solve the problems of high heat loss in manufacturing materials, manufacturing costs, increased seawater pretreatment burden, and increased device costs, so as to reduce equipment corrosion, Equipment layout and pipeline design are simple and the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

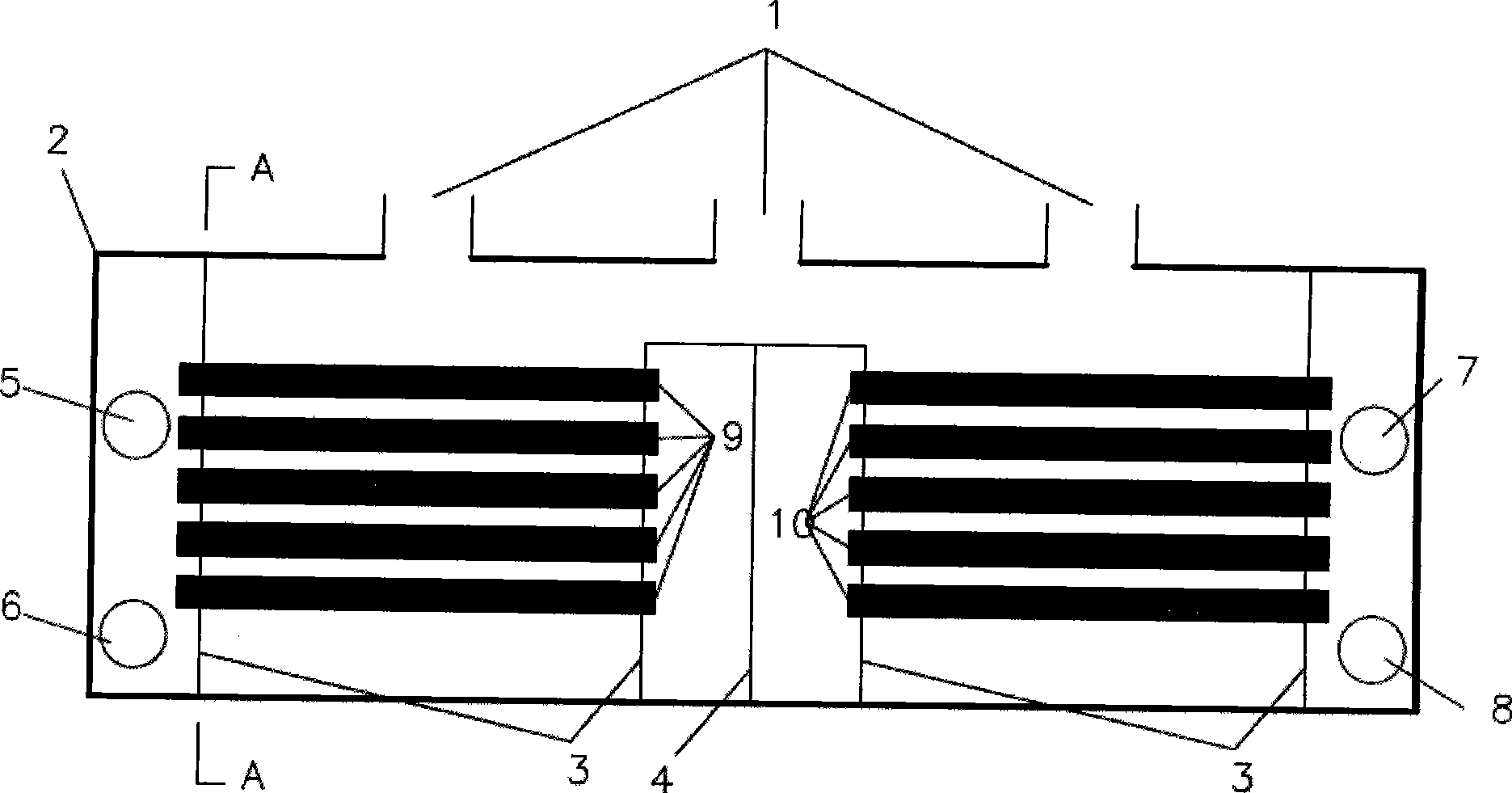

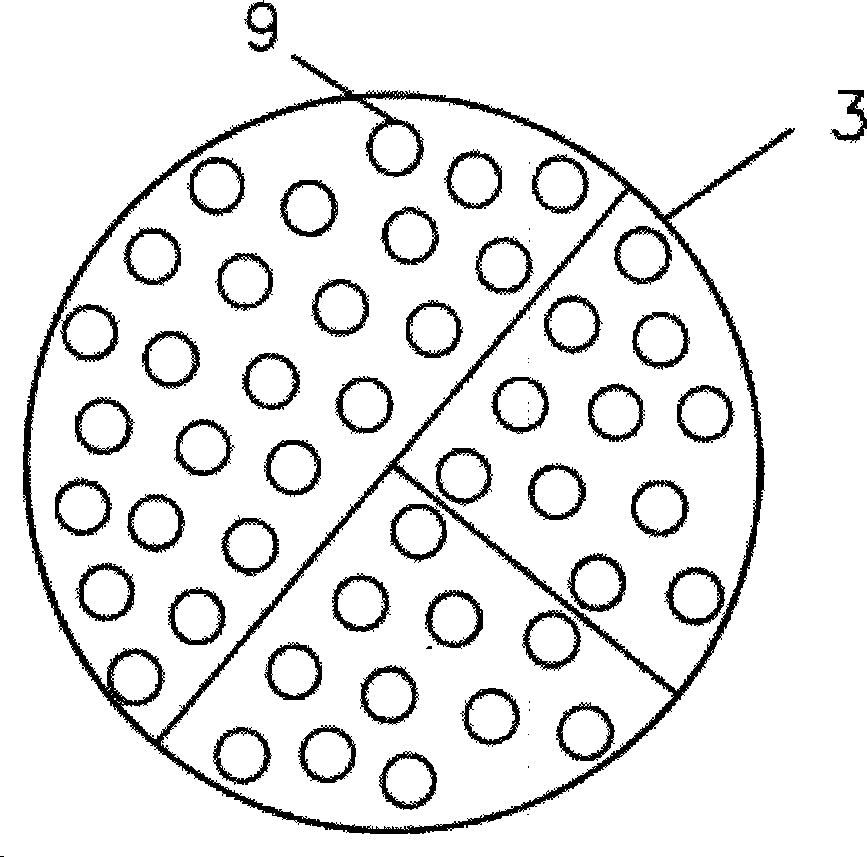

[0027] Embodiment: a kind of low-temperature multi-effect seawater desalination final effect condenser (see figure 1 ), which is characterized in that it consists of a shell 2, feed seawater heat exchange tubes 9, cooling water heat exchange tubes 10, tube sheets 3 and intermediate partitions 4, wherein the top of the shell 2 has the final secondary steam The inlet 1 has feed seawater inlet 5 on both sides; said tube sheet 3 is connected in the shell 2; said feed seawater heat exchange tube 9 and cooling water heat exchange tube 10 are respectively connected on the tube sheet 3 , and there is an intermediate partition 4 between the feed seawater heat exchange tube 9 and the cooling water heat exchange tube 10; 5. The water outlet is connected to the feed seawater outlet 6; the cooling water heat exchange tube 10 constitutes a condenser, the water inlet is connected to the cooling water inlet 7, and the water outlet is connected to the cooling water outlet 8.

[0028] The abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com