CO2 sorbent and preparation method thereof

A technology of adsorbent and surfactant, which is applied in the field of CO2 adsorbent and its synthesis of amino-modified mesoporous materials, which can solve the problems of reduced adsorption performance and limited application range, and achieve the effect of improved adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

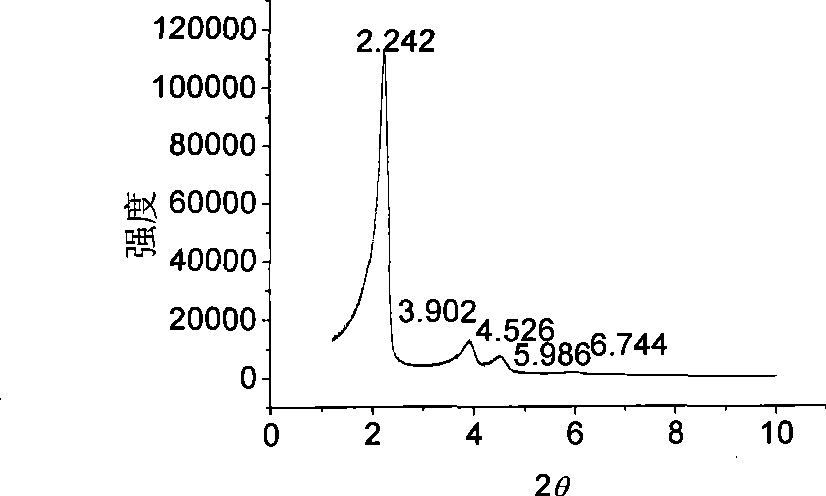

[0027] Implementation Example 1 (APTS-MCM-41)

[0028] The pre-synthesized MCM-41 was dried in a vacuum oven at 80°C for 10 hours. Weigh 1g of the treated MCM-41, add it into 100ml tetrahydrofuran, and stir evenly at room temperature. Then, 6 mL of aminopropyltriethoxysilane (APTS) was added dropwise, followed by stirring for 1 hour. The reaction solution was slowly heated to 30° C. for 10 hours. After the reaction, the reaction solution was suction filtered and washed with tetrahydrofuran. The resulting solid sample was activated in a vacuum oven at 80°C for 10 hours. Samples were characterized and CO 2 Adsorption performance test.

Embodiment 2

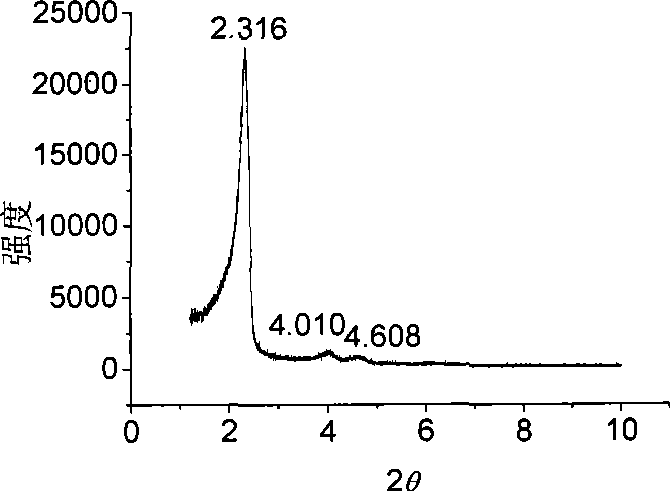

[0029] Implementation Example 2 (APTS-SBA-15)

[0030] The pre-synthesized SBA-15 was dried in a vacuum oven at 150°C for 12 hours. Weigh 1g of the treated SBA-15, add it into 100ml of anhydrous toluene, and stir evenly at room temperature. Then, 8 mL of aminopropyltriethoxysilane (APTS) was added dropwise, followed by stirring for 1 hour. The reaction solution was slowly heated to 60° C. for 20 hours. After the reaction was completed, the reaction solution was suction filtered and washed with anhydrous toluene. The obtained solid sample was activated in a vacuum oven at 150° C. for 10 hours. Samples were characterized and CO 2 Adsorption performance test.

Embodiment 3

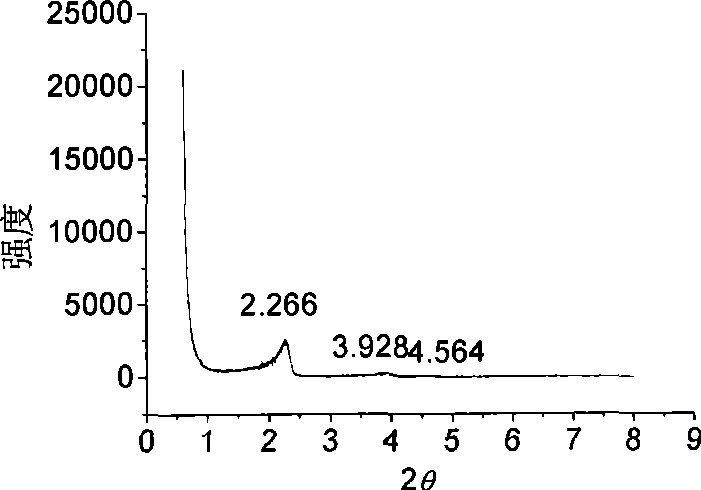

[0031] Implementation Example 3 (AEAPMDS-MCM-41)

[0032] The pre-synthesized MCM-41 was dried in a vacuum oven at 100°C for 10 hours. Weigh 1g of the treated MCM-41, add it into 100ml tetrahydrofuran, and stir evenly at room temperature. Then, 2 mL of aminoethylaminopropylmethyldiethoxysilane (AEAPMDS) was added dropwise, and stirred for 1 hour. The reaction solution was slowly heated to 60° C. for 15 hours. After the reaction, the reaction solution was suction filtered and washed with tetrahydrofuran. The obtained solid sample was activated in a vacuum oven at 120° C. for 10 hours. Samples were characterized and CO 2 Adsorption performance test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com