Extra high voltage line multifunctional combined galloping

A multi-functional combination, UHV technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of poor operation safety and high labor intensity, and achieve the effect of improving construction efficiency, reducing labor intensity and spacious space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

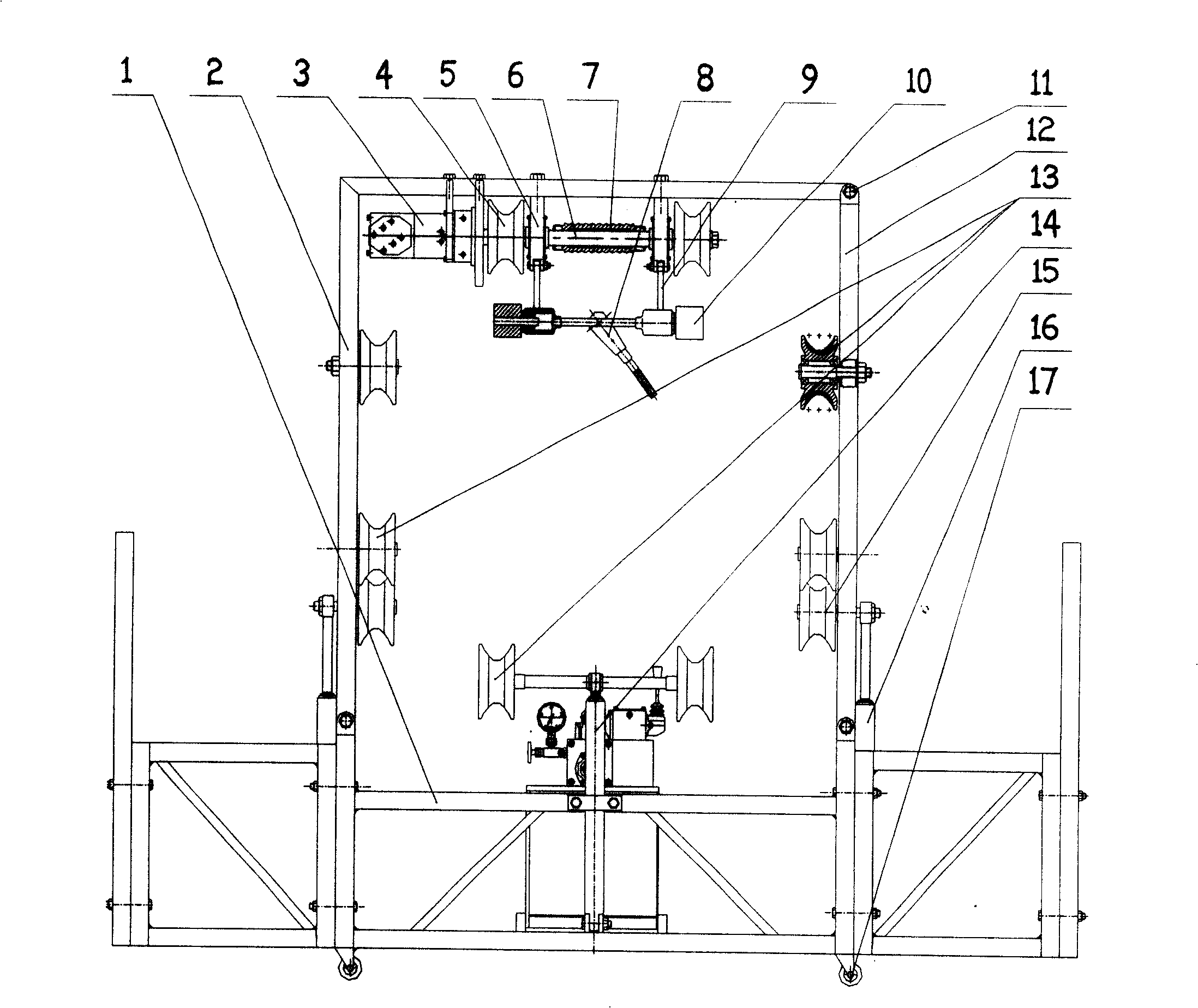

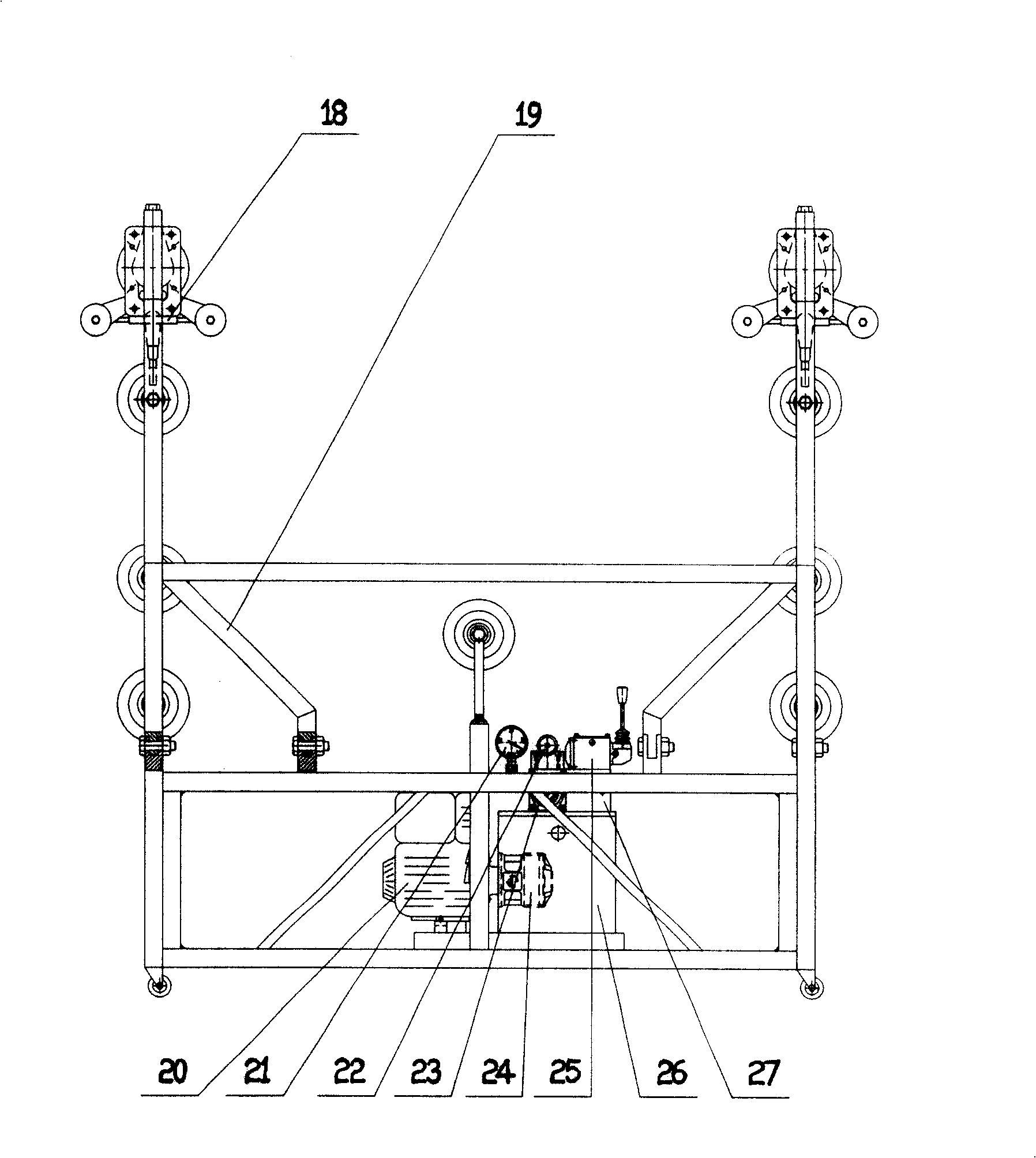

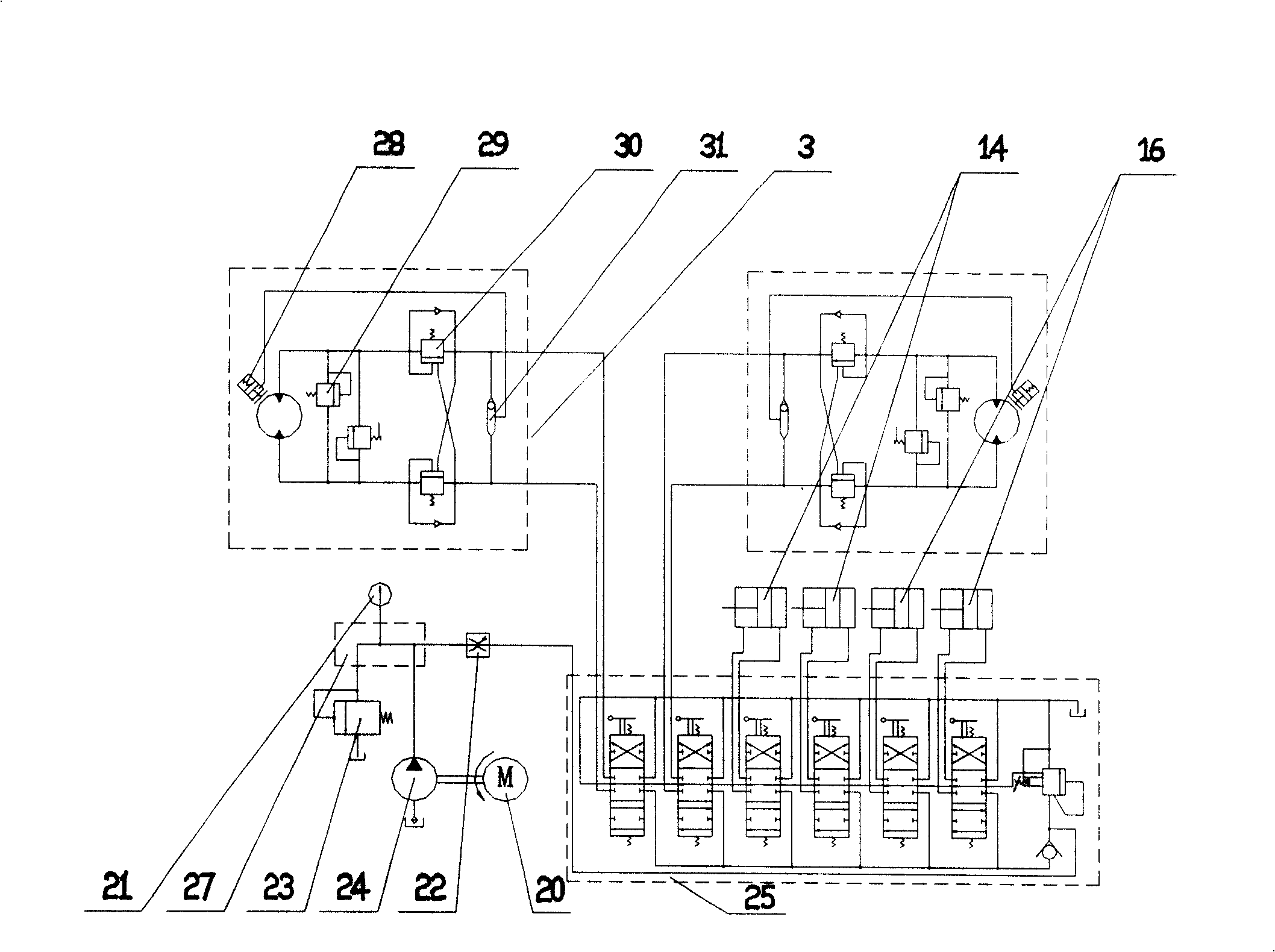

[0014] Reference figure 1 , figure 2 , The present invention includes a base 1, a frame, a drive shaft 6, a drive wheel 4, and a support wheel 13. The frame is composed of two sets of front and rear support arms and auxiliary arms 19, which are hinged to the base 1, and the support arms It is formed by connecting the big arm 2 and the small arm 12 through the pin shaft 11. The big and small arms of the front and rear supporting arms are installed in opposite directions. Two coaxial bearing seats 5 are provided under the cross beam of the big arm 2. A drive shaft 6 with a drive winch 7 is provided on the upper part. Both ends of the drive shaft 6 are provided with drive wheels 4, which are connected to the main shaft of the hydraulic motor assembly 3 in the power output mechanism. Two movable arms 9 that are controlled by the screw 18 to open or close are respectively connected. Each movable arm 9 is provided with a clamping wheel 10 corresponding to the driving wheel 4 above. By...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com