Image sensor and fabrication method thereof

A technology of an image sensor and a manufacturing method, which is applied in the field of image sensors, can solve the problems that optical waveguides are not widely used in sensors, and the complexity and manufacturing cost of image devices are increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

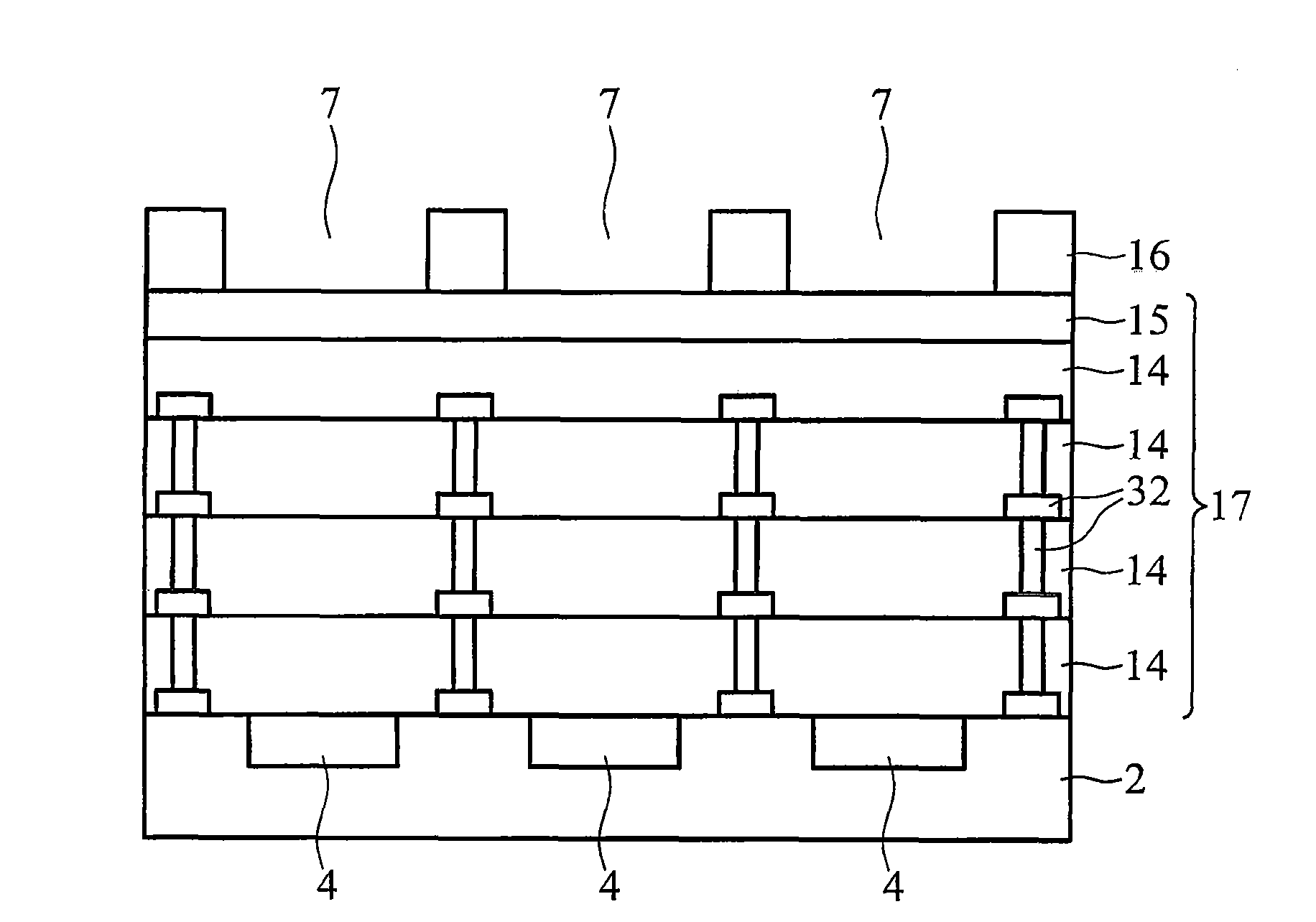

[0026] Embodiments of the present invention provide a method for manufacturing a photo-sensing integrated circuit and an image sensor. The manufacturing and usage methods of each embodiment are described in detail below and illustrated with accompanying drawings. Wherein, the same reference numerals used in the drawings and the specification represent the same or similar components. In the accompanying drawings, for the sake of clarity and convenience of illustration, the shapes and thicknesses of the embodiments may be unrealistic. The following description is specifically directed to the various elements of the device of the present invention or their integration. However, it is worth noting that the above-mentioned elements are not particularly limited to what is shown or described herein, but can be familiar with the ordinary technology in this technical field. In addition, when a material layer is on top of another material layer or substrate, it may be directly on its su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com