Full-automatic alkali-dipping, rinsing and marinating production line

A production method and fully automatic technology, applied in food preparation, application, food science and other directions, can solve the problems of large manual labor, unstable product quality, low production efficiency, etc., to reduce manual intervention and reduce manual labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

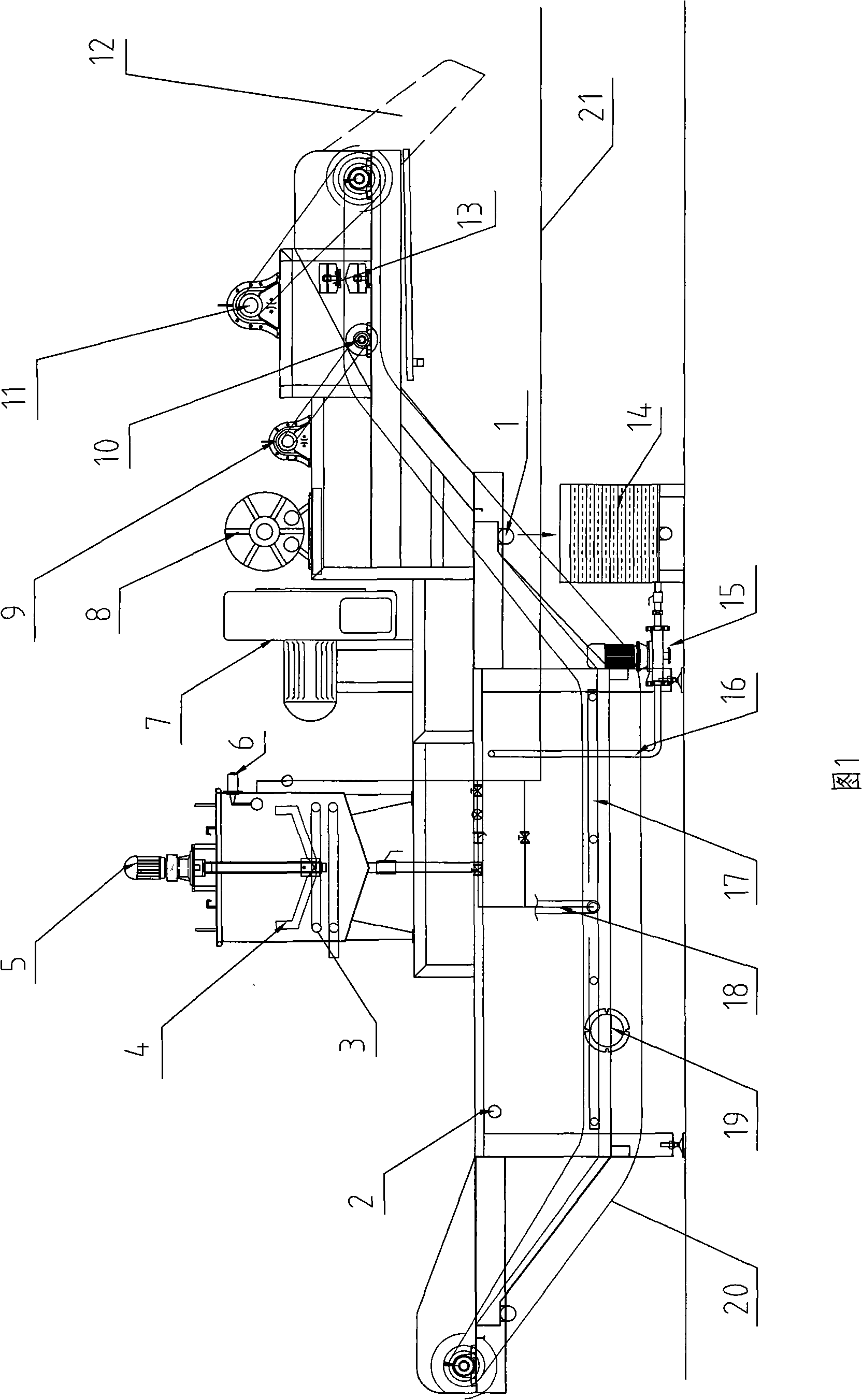

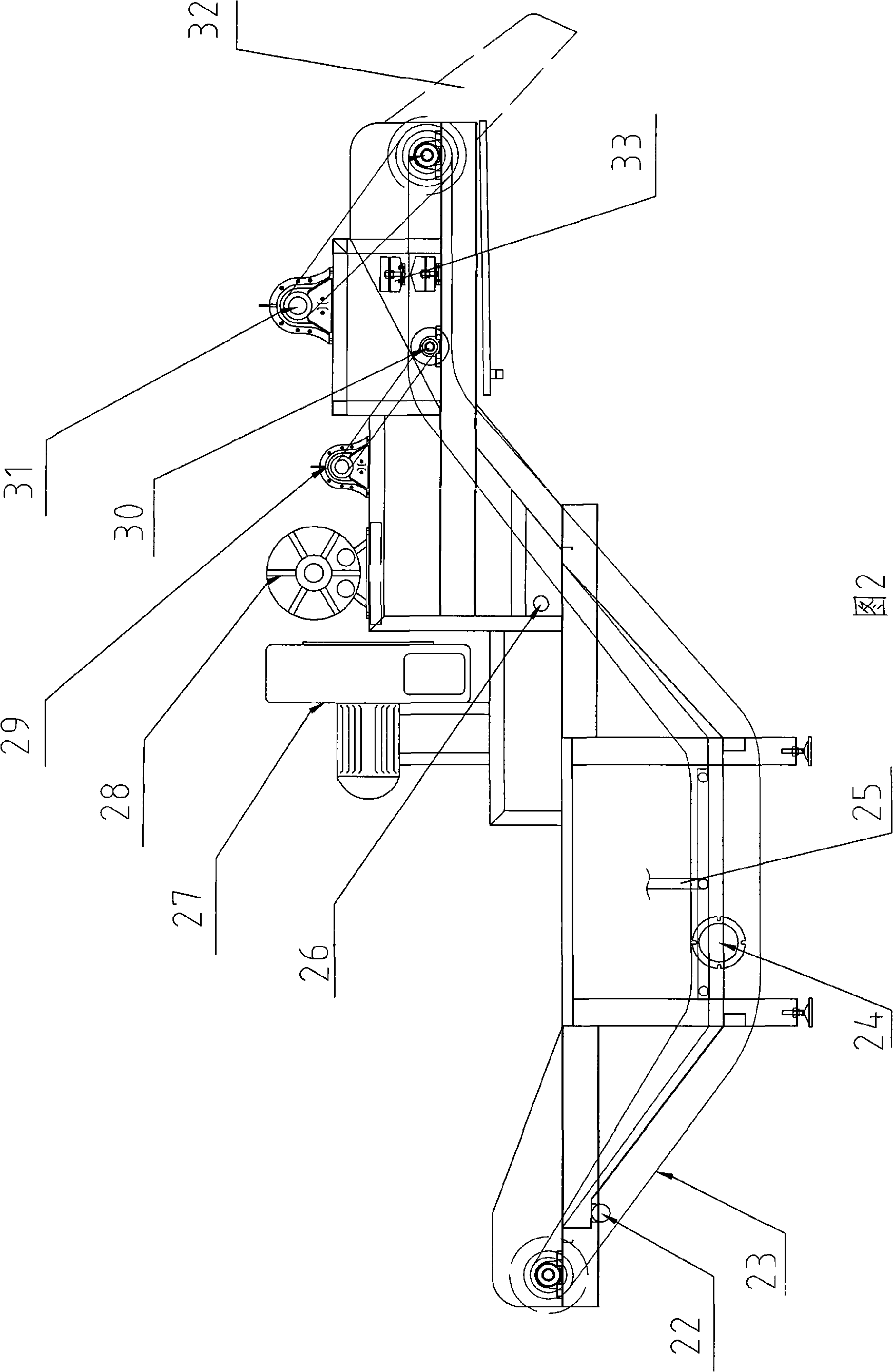

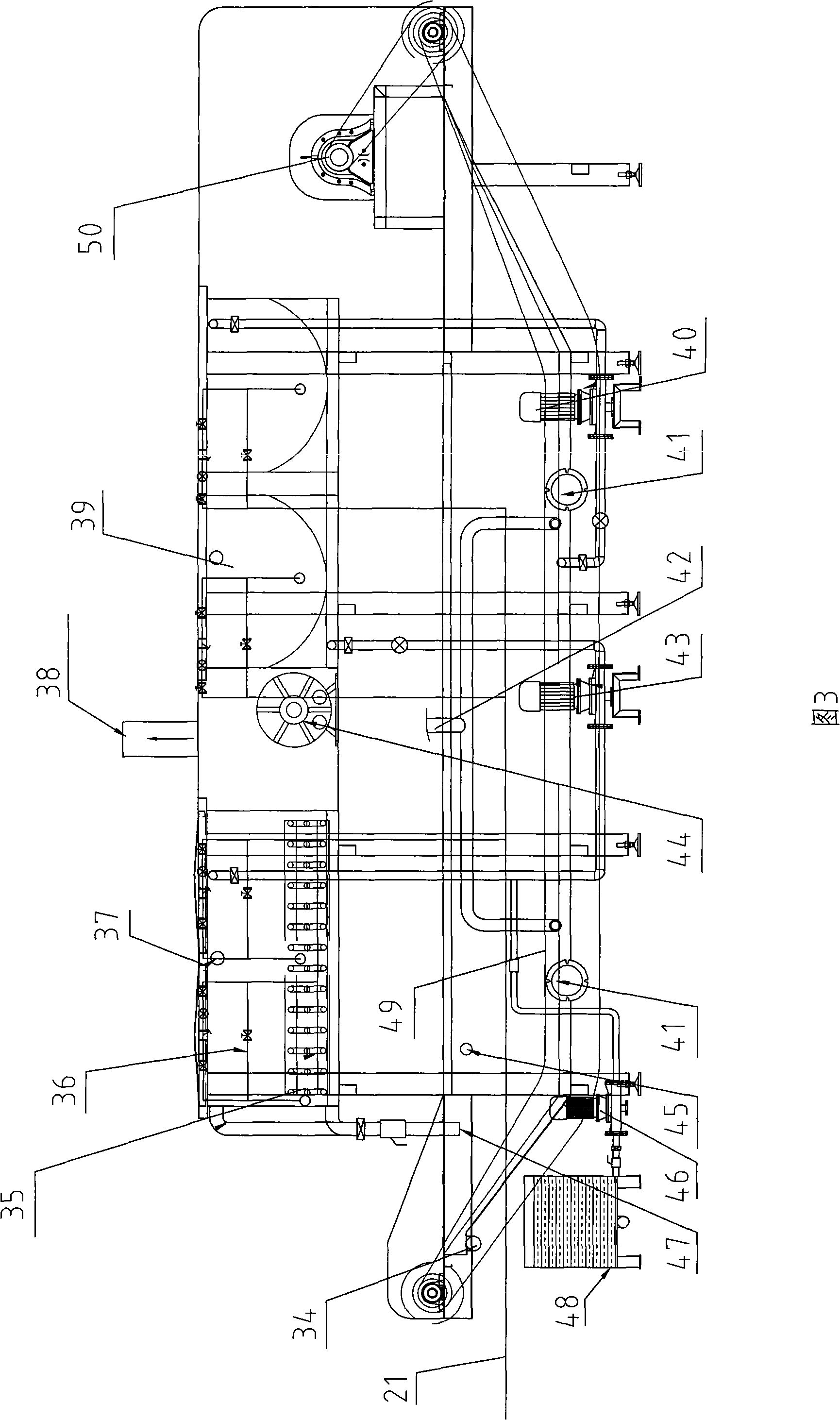

[0018] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0019] The fully automatic production method of soda, rinsing and brine includes three processes of soda, rinsing and brine. In the soda process, the materials are transported by the conveyor network controlled by the automatic control device, and the alkalinity of the soda is passed by the automatic control device. After the pH value detector is detected, the lye delivery valve is controlled to adjust. After the lye is finished, the material is dewatered by the dewatering mechanism during the conveying process on the conveying network, and then transported into the rinsing process; in the rinsing process, the material is automatically The conveying network controlled by the control device, after the material is rinsed, is dewatered by the dewatering mechanism during the conveying process on the conveying network, and then transported into the marin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com