Baking sagger for lithium battery material

A lithium battery material and roasting technology, which is applied in the direction of charge manipulation, furnace, lighting and heating equipment, etc., can solve the problems of easy cracking and large structural stress of the saggar, so as to achieve less cracks, improve product quality and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

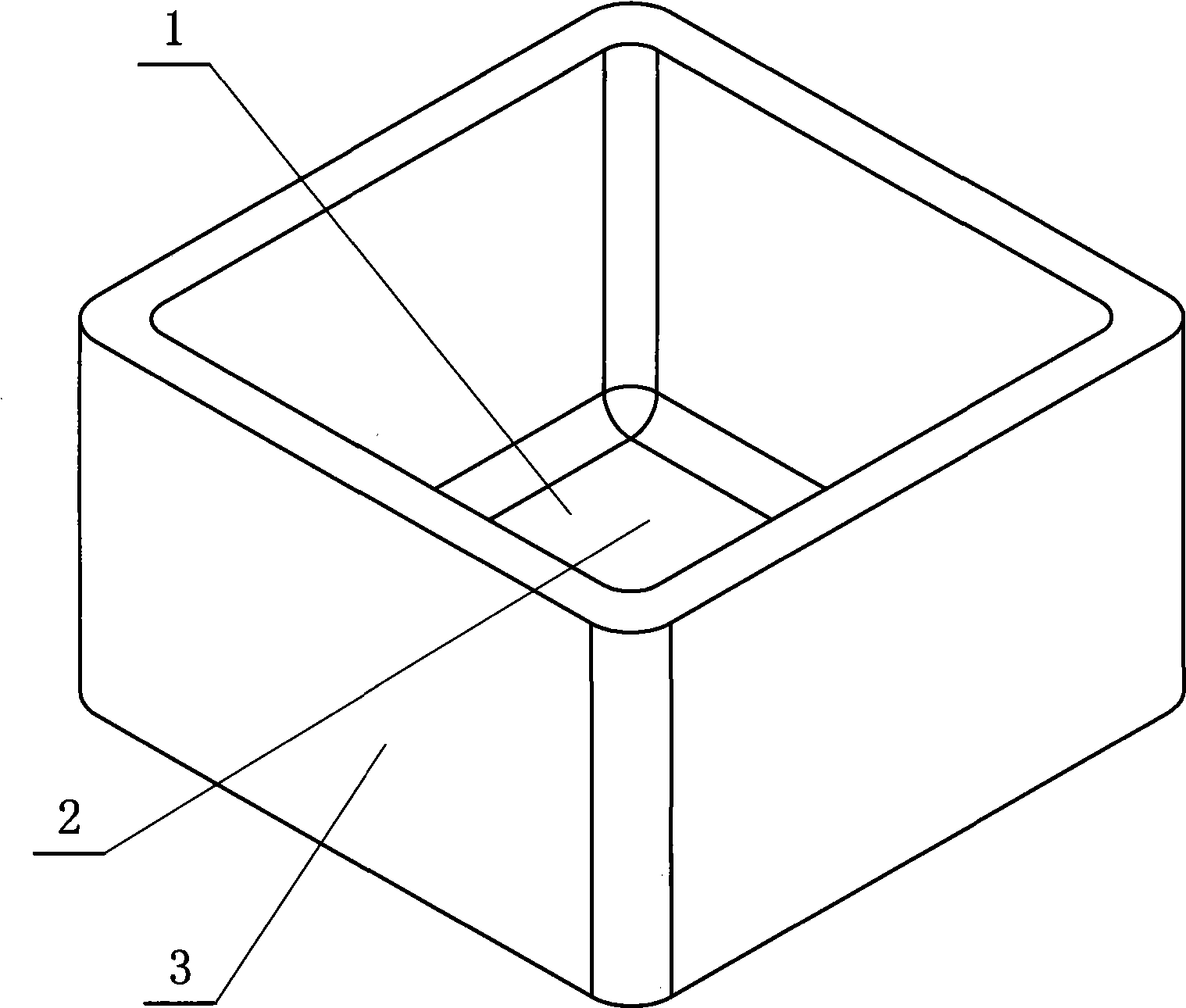

[0010] refer to figure 1 It is an embodiment of the firing sagger for the lithium battery material of the present invention, including a side wall 3 and a bottom surface 1, the side wall 3 and the bottom surface 1 enclose a concave cavity 2 for firing, and a circular arc transition is formed between the side walls 3 , the transition between the side wall 3 and the bottom surface 1 is a circular arc, the cross-sectional shape of the cavity 2 is a polygon or a regular polygon, such as a regular quadrangle, and the side wall 3 in the cavity 2 and the side wall 3 , The transition between the side wall 3 and the bottom surface 1 is a circular arc, the thickness of each part on the side wall 3 of the sagger is equal, and the thickness of the adjacent side walls 3 is equal.

[0011] The above-mentioned lithium battery material roasting sagger is made with the following formula, including the following components, and the weight percentage of each component is: 45% to 70% of aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com