Control method for fermentation temperature in daqu liquor production cellar

A technology of fermentation temperature and control method, which is applied in the preparation of alcoholic beverages, etc., which can solve the problems of excessive production of acids and aldehydes, affecting cellars, and rapid cooling, and achieve normal production, shortened fermentation time, The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

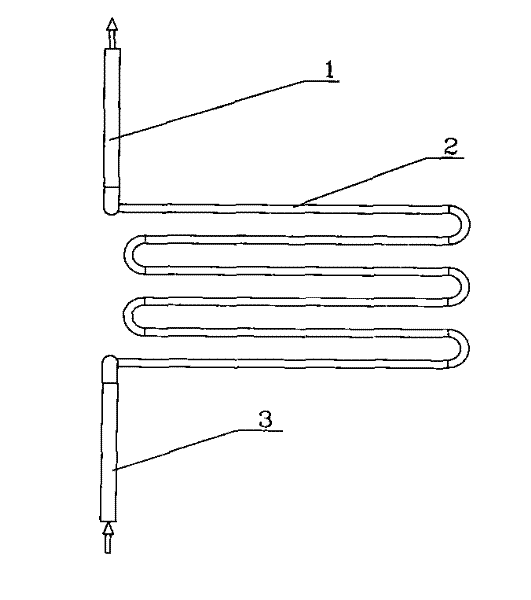

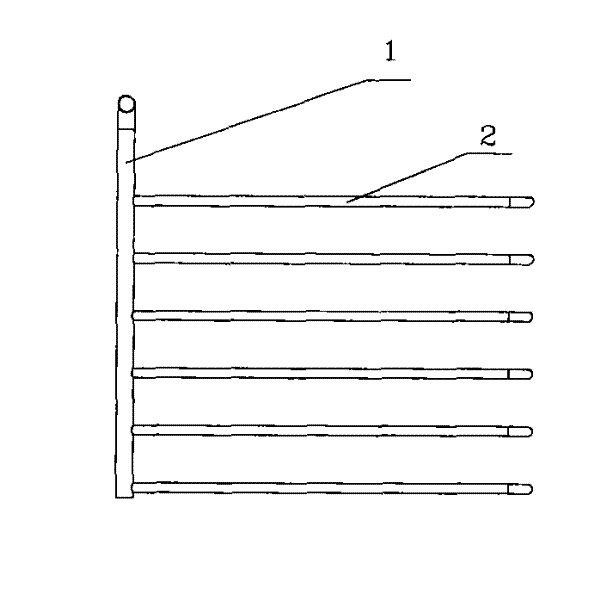

[0023] Such as figure 1 , figure 2 As shown, in this embodiment, multi-layer heat exchange tubes with horizontal tube diameters are arranged in the Daqu wine cellar pool. The tube spacing of each layer of heat exchange tubes in the horizontal direction is 60 cm, and the layer spacing of each layer of heat exchange tubes is 40 cm. All heat exchange tubes are connected in parallel.

[0024] The cooled grain troughs are hoisted into the cellar pond equipped with heat exchange tubes by driving in stages, and the cellar is stepped on, and the cellar is sealed after entering the cellar. In summer, 2 to 3 days after the grain grains enter the cellar, the cooling water that is 3°C to 10°C lower than the temperature in the cellar is passed into the cellar, so that the temperature in the cellar slowly rises to 33°C to 38°C in 8 to 15 days. ℃, until the temperature no longer rises, reduce the amount of cooling water, and finally stop the cooling water. When the temperature in the cel...

Embodiment 2

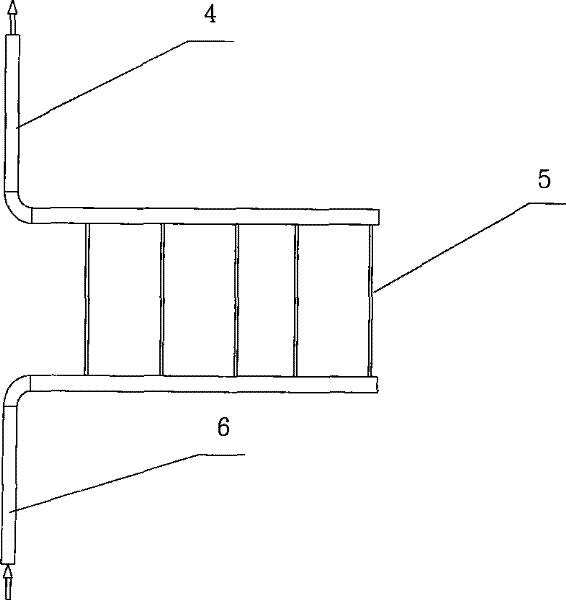

[0027] Such as image 3 , Figure 4 As shown, in this embodiment, vertically arranged heat exchange plates are used as heat exchange components, and the heat exchange plates are arranged at a distance of 70 cm in the cellar, and the heat exchange plates are connected in parallel. After the installation of the heat exchange plate in the cellar is completed, the cooled grain troughs are hoisted into the cellar in stages by driving, and the cellar is stepped on, and the cellar is sealed after entering the cellar. 2 to 3 days after the winter grain grains are put into the cellar, the production waste hot water or hot water that is 3°C to 10°C higher than the temperature of the mother grains in the cellar is passed into the cellar, so that the temperature in the cellar rises to 8-15 days. After 29 ℃ ~ 38 ℃, reduce until stop feeding production waste hot water or hot water. When the temperature of the cellar begins to drop below the maximum temperature by 2°C to 3°C, the productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com