Preparation and stabilization of high-purity xanthophyll ester and method for removing pollutant thereof

A high-purity technology for lutein esters, applied in the field of phytochemistry, can solve the problems of poor stability, low yield of lutein esters, and high residual amount of heavy metal substances, so as to increase the content, avoid solvent crossover, and solve the problem of poor yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

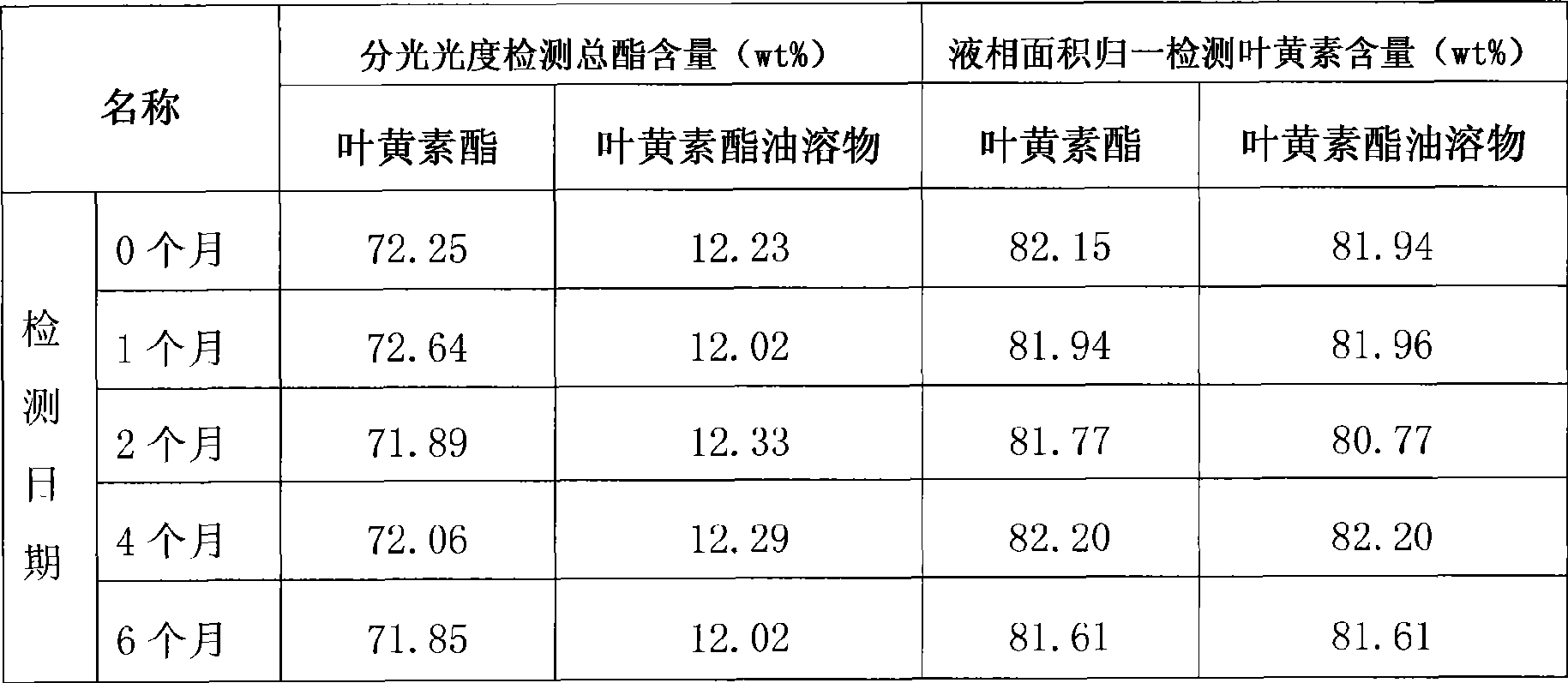

Examples

Embodiment 1

[0026] Weigh 100 g of marigold flower grains with a total ester content of 4.1 wt % and mix with 1000 g of acetone, heat and stir at 70° C. for 0.5 hour and then filter to obtain an acetone extract. Add 50g of EDTA sodium salt and 50g of white clay to the acetone extract, stir at 70°C for 0.5h, filter, and remove the acetone in a vacuum to obtain the concentrate (the dissolved residue of the concentrate must be controlled to be less than 3% of its mass). Add tert-butanol 10 times the mass of the concentrate, stir and dissolve at 50°C for 1 hour, then slowly cool the solution to 10°C.

[0027] After the solution was placed at 10° C. for 18 hours, it was filtered to obtain a filter cake, which was mixed with 15 times the mass of methanol and washed with stirring. The washing times were three times, each time using methanol 5 times the mass of the solid. Add 0.5g of antioxidant vitamin E to the solid after fully washing with methanol, and dry it at 30°C for 24 hours to obtain 15g...

Embodiment 2

[0029] Weigh 100 g of marigold flower grains with a total ester content of 4.1 wt%, mix with 2000 g of acetone, heat and stir at 40° C. for 1.0 hour and then filter to obtain an acetone extract. Add 15g of EDTA sodium salt, 15g of attapulgite and 8g of white clay to the acetone extract, stir at 60°C for 1 hour, filter, and remove the acetone in a vacuum to obtain a concentrate (the dissolved residue of the concentrate must be less than 3% of its mass). Add isopropanol 3 times the mass of the concentrate, stir and dissolve at 40°C for 2h, then cool the solution slowly to 5°C.

[0030] After the solution was placed at 5° C. for 12 hours, it was filtered to obtain a filter cake, which was mixed with 9 times the mass of methanol and washed with stirring. The number of washings was three times, each time with 3 times the mass of solid methanol. Add 0.4g of the antioxidant vitamin C sodium salt to the solid after fully washing with methanol, and dry it at 40°C for 16 hours to obtain...

Embodiment 3

[0032] Weigh 120 g of marigold flower grains with a total ester content of 4.8 wt % and mix with 1500 g of n-butane, heat and stir at 20° C. for 5 hours and then filter to obtain n-butane extract. Add 12g of clay to the n-butane extract, stir at 30°C for 4h, filter, and remove the n-butane in a vacuum to obtain a concentrate (controlling the dissolved residue of the concentrate must be less than 3% of its mass). Add n-butanol with 1 times the mass of the concentrate, stir and dissolve at 20°C for 5h, then cool the solution slowly to 0°C.

[0033] After the solution was placed at 0°C for 10 hours, it was filtered to obtain a filter cake, which was mixed with ethanol 3 times its mass and washed with stirring. The washing times were three times, each time with ethanol 1 times the mass of the solid. Add 0.8g of antioxidant vitamin E to the solid washed with ethanol, and dry it at 45°C for 10 hours to obtain 13g of the product, which contains 90% of the mass percentage of lutein es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com