Heating type electro-chemical trace amount detection pool integrated on conductive glass

A conductive glass and detection cell technology, applied in the direction of material electrochemical variables, etc., can solve the problems of aggravating waste liquid pollution, refractory solution, environment, etc., to achieve elimination of adsorption phenomenon, sensitive electrolytic current, and good detection reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

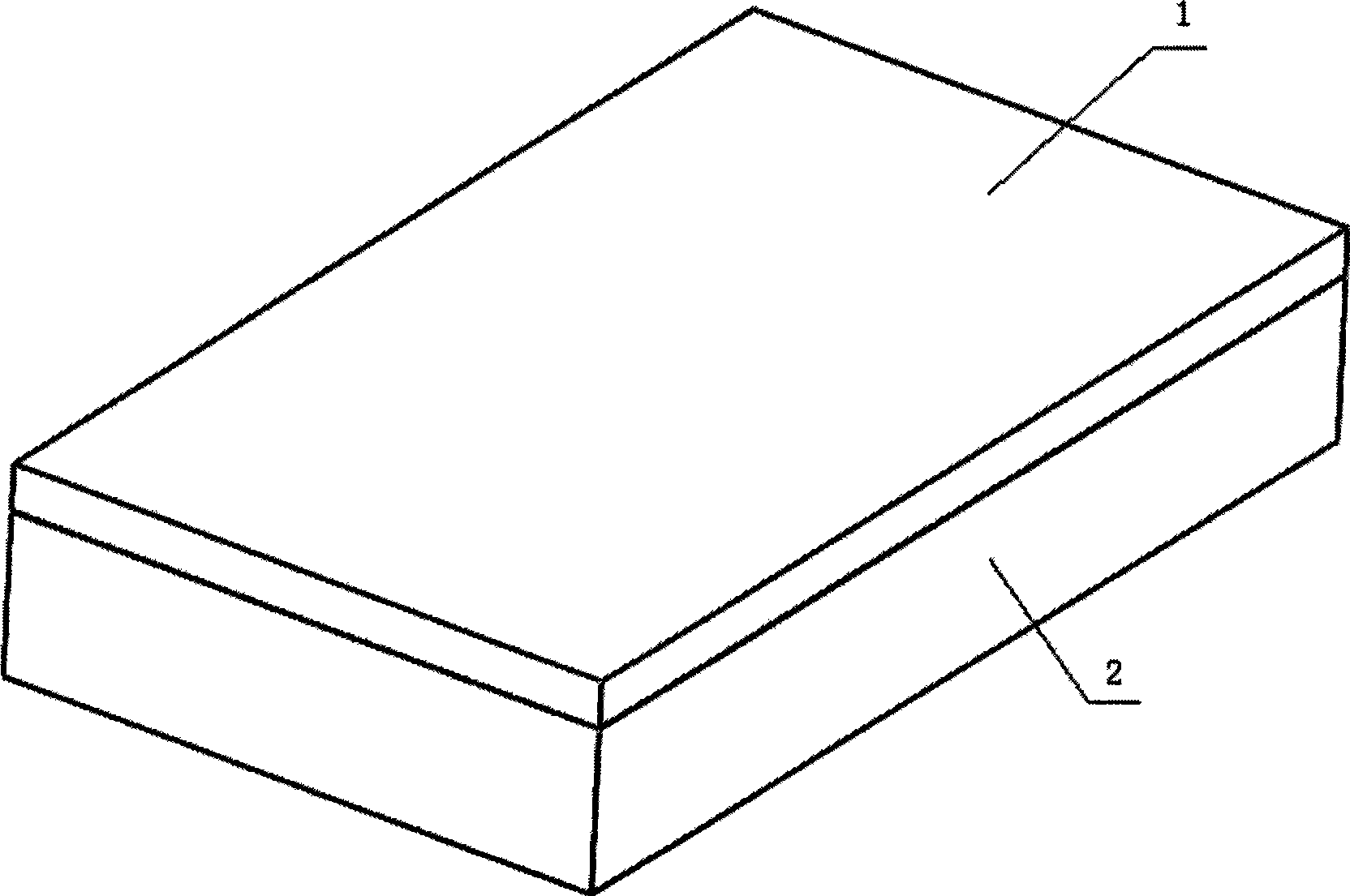

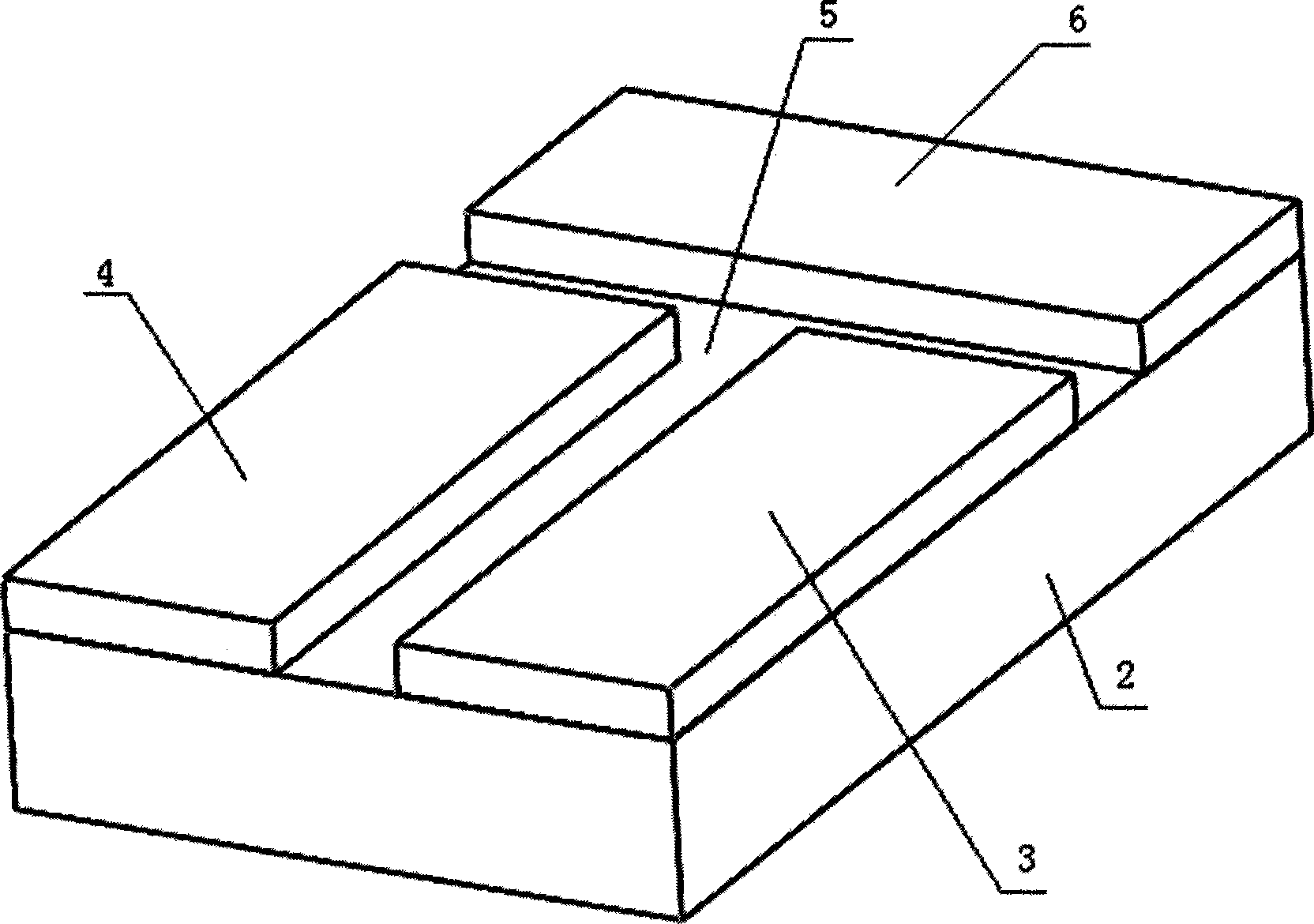

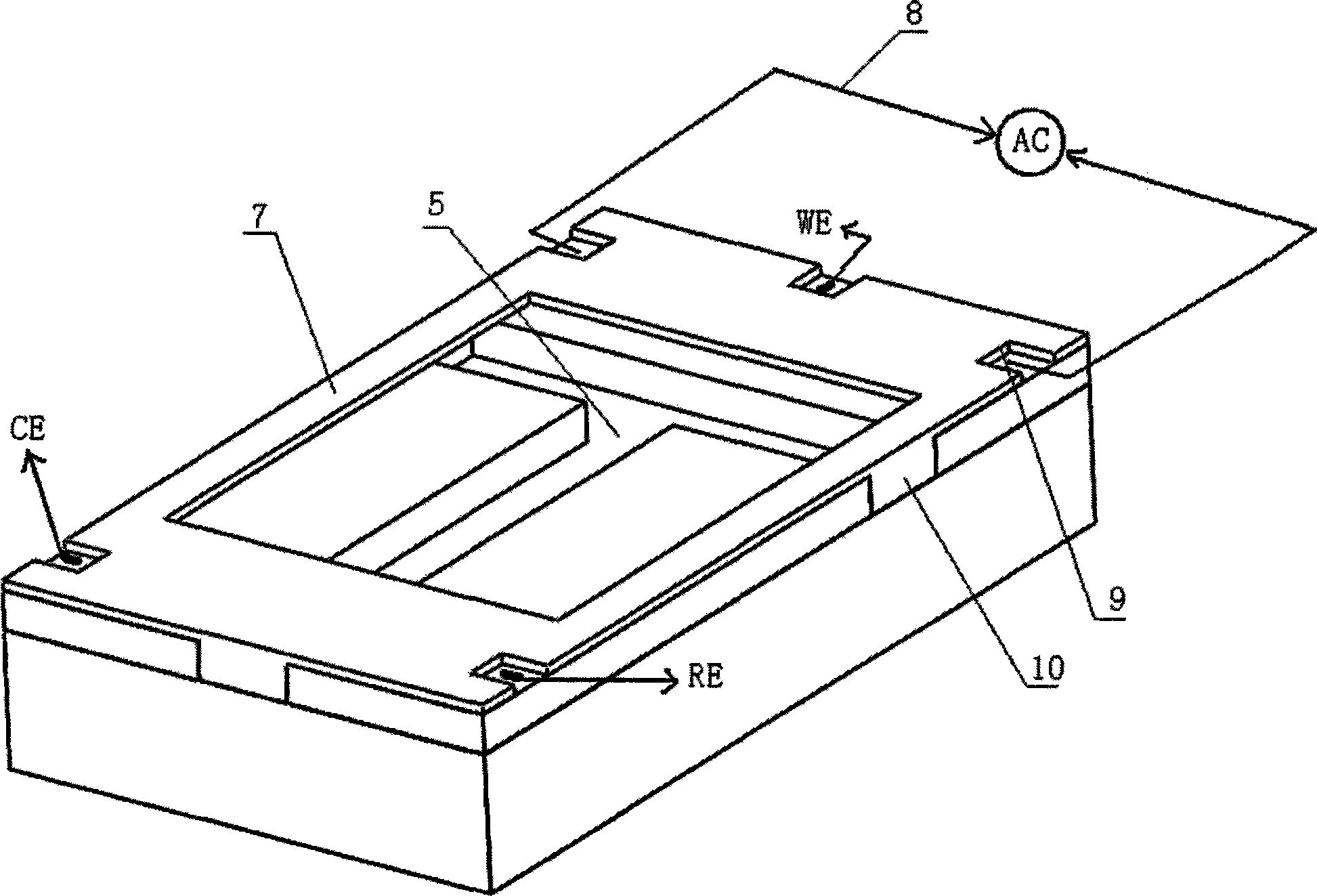

[0011] As shown in the figure, the heating type electrochemical micro detection cell integrated on the conductive glass of the present invention includes a conductive glass with a conductive layer on the surface, the conductive glass includes a glass matrix 2 and a conductive layer 1, and is characterized in that: the conductive glass The conductive layer is etched with acid to form three parts insulated from each other, which are respectively used as the working electrode 6, the auxiliary electrode 4 and the reference electrode 3 to form a full ITO three-electrode system; wherein the ITO working electrode is connected to the heating circuit 8 to realize the working electrode. Heating; the top of the ITO three-electrode system is covered with an insulating thin layer 7, and the insulating thin layer is provided with a three-electrode connection port 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com