A method for separating and purifying glycopeptides

A technology for separation and purification of glycopeptides, applied in the field of separation and purification of glycopeptides with magnetic particles, can solve the problems of complicated procedures for separation and purification of glycopeptides, long separation and purification reaction time, etc., and achieve the effect of optimizing coupling conditions and rapid separation and purification reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

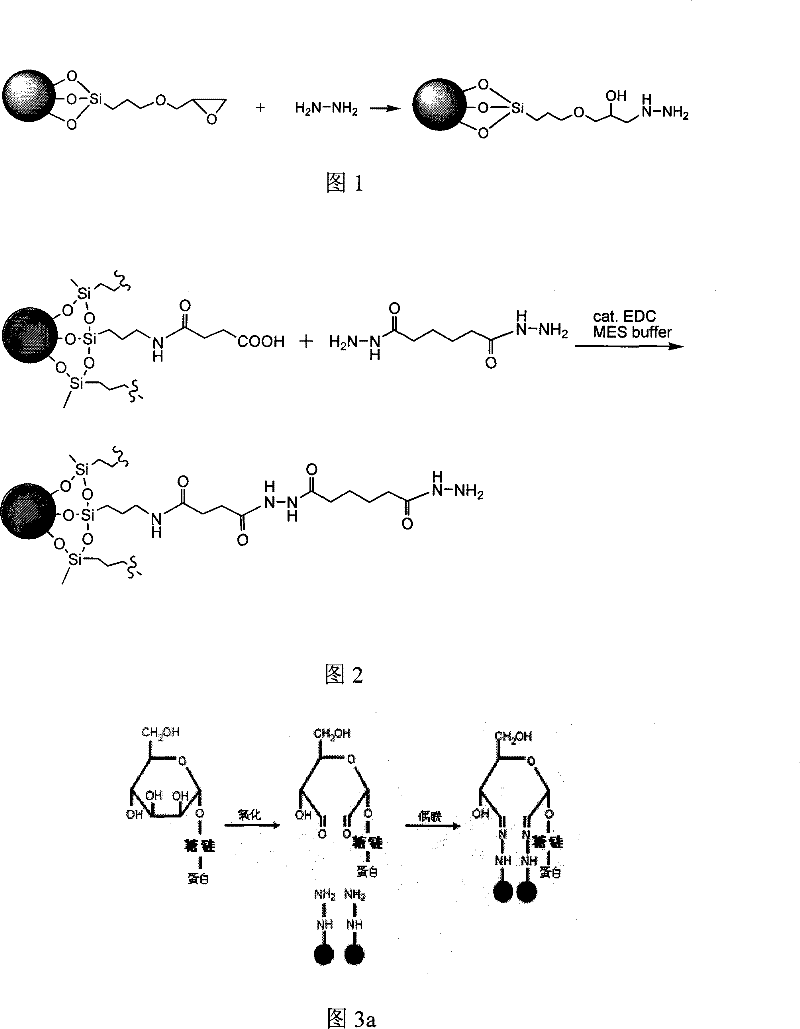

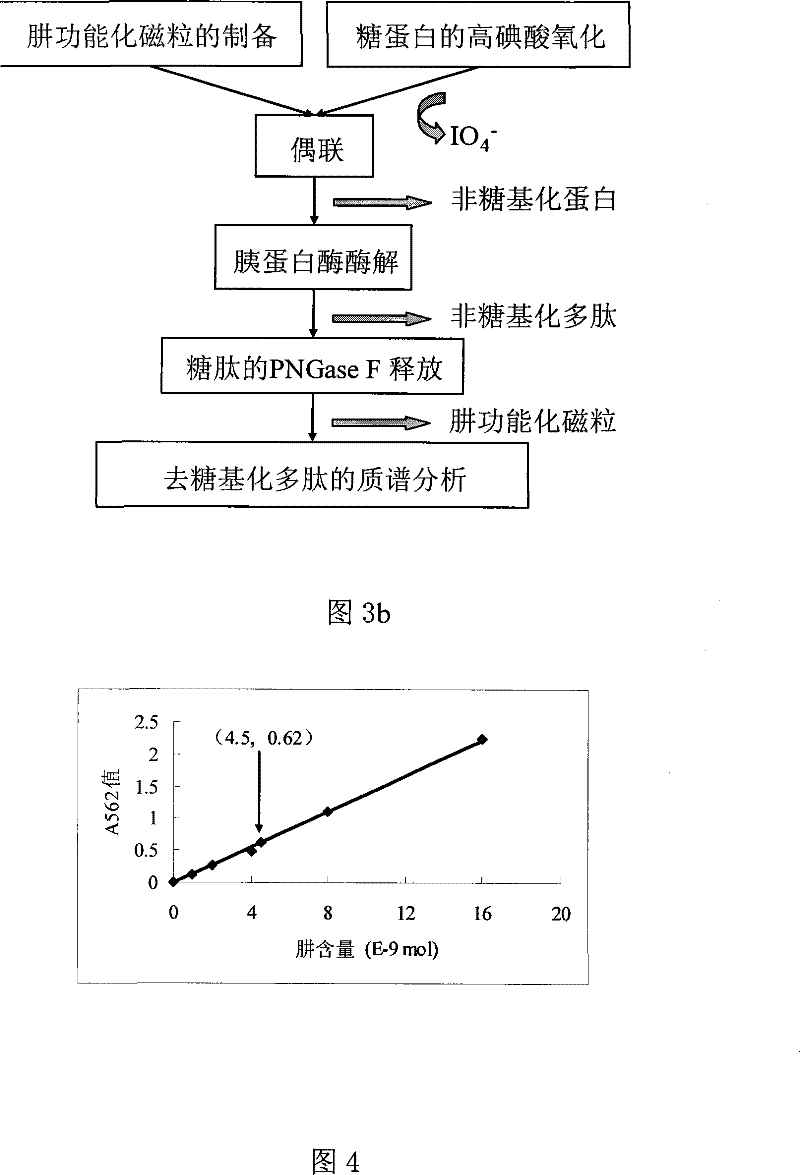

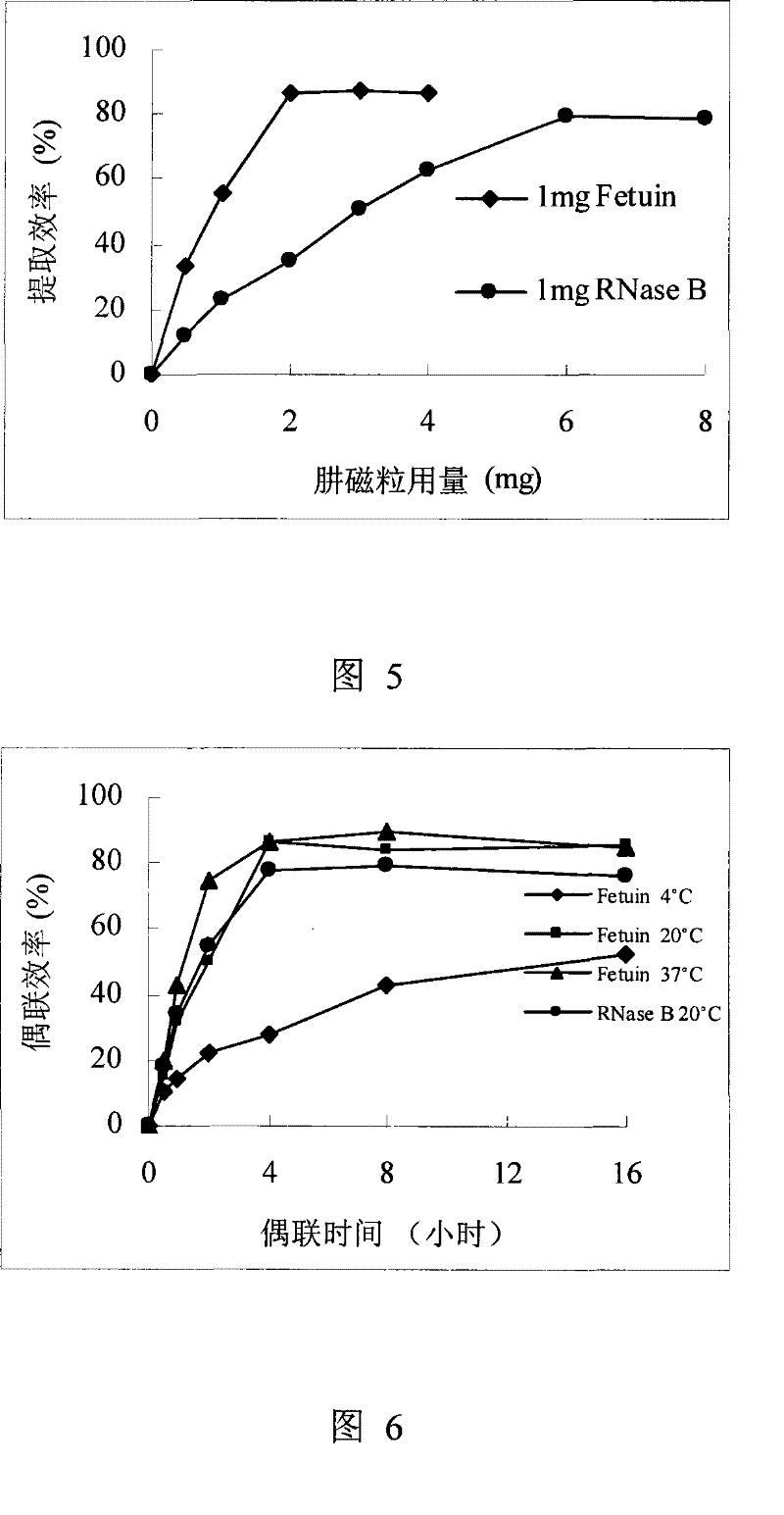

[0089] see figure 1 and Figure 3, the method for separating and purifying glycopeptides

[0090] (1) Separation and purification of glycopeptides

[0091] (1-1) Preparation of hydrazine functionalized magnetic particles

[0092] a cleaning

[0093] Get 200 mg of epoxidized magnetic particles and place them in a flask, wash them with water, put the flask filled with the suspension on a magnetic separator for magnetic separation after cleaning, and remove the upper layer of clear liquid that does not contain magnetic particles; it can be ordinary water, But it is better to use water without impurities, such as ultrapure water and double distilled water (twice distilled water).

[0094] b reaction (modification)

[0095] Add 50 milliliters of hydrazine hydrate with a mass fraction of 5% in the flask, place the flask in a water bath, insert a stirrer into the flask, turn on the stirrer and stir to fully mix the magnetic particles and hydrazine hydrate, and react for 3 hours. ...

Embodiment 2

[0112] (1-1) Preparation of hydrazide functionalized magnetic particles

[0113] a cleaning

[0114] Get 200 mg of carboxylated magnetic particles and place them in a flask, wash them with water, add 0.1 mole of 2-(N-morpholine) ethanesulfonic acid (MES) buffer solution of pH 4.75 for pretreatment, and wash The flask containing the suspension is placed on a magnetic separator for magnetic separation, and the upper layer of clear liquid without magnetic particles is removed; it can be ordinary water, but it is better to use water without impurities, such as ultrapure water and double distilled water (twice distilled water).

[0115] b reaction (modification)

[0116]Add 50 ml of 2-(N-morpholine)ethanesulfonic acid (MES) buffer solution containing 1 gram of adipic dihydrazide (ADH) to the flask, put the flask into a water bath, insert a stirrer, and turn on the stirrer to stir , add 0.5 g of carbodiimide (EDC) during stirring, continue to stir and react for more than 3 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com