Anaerobic-aerobic combined biological treatment method for oily wastewater of cold rolling mill

A biological treatment and anaerobic treatment technology, applied in metallurgical wastewater treatment, aerobic and anaerobic process treatment, water/sewage multi-stage treatment, etc., can solve the problems of cumbersome equipment operation, high investment cost, and increased operating cost, Achieve the effect of low processing cost, low equipment investment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

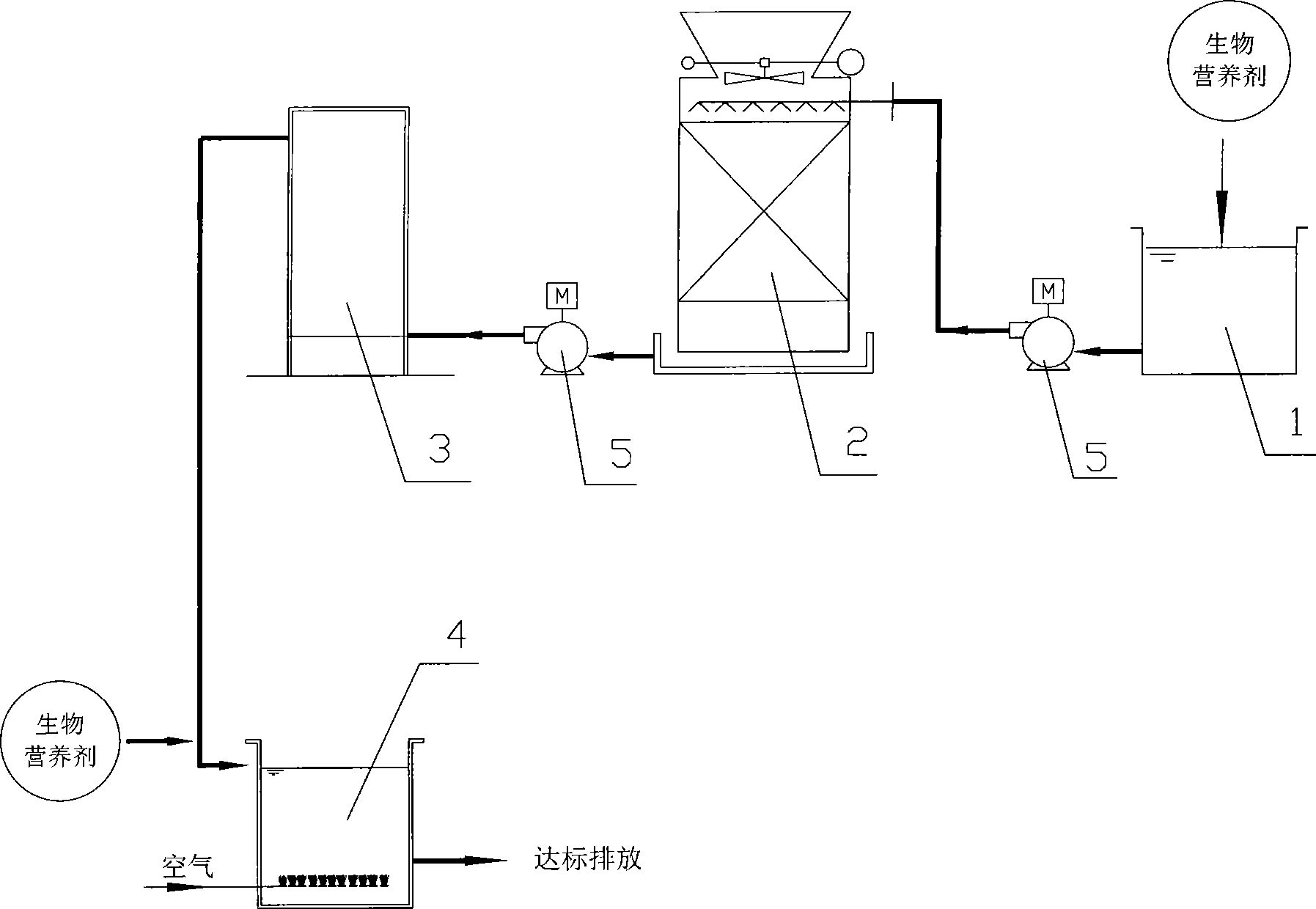

[0021] Below in conjunction with accompanying drawing, take the oily wastewater treatment of Wuhan Iron and Steel Group Cold Rolling Steel Plant as an example, the present invention is further explained:

[0022] After the oily wastewater from the cold rolling steel mill is treated at the first stage, the indicators in the oily wastewater are: SS less than 300mg / L, oil less than 30mg / L, COD Cr Less than 4000mg / L.

[0023] (1) Pre-treatment: Send the oily wastewater after the primary treatment to the regulating tank 1, add biological nutrients urea and ammonium dihydrogen phosphate, so that the nutrient ratio meets COD Cr :N:P=200-300:5:1, NH 3 -N<1000mg / L, at the same time add the following trace elements in proportion, Fe=0.5-1.5mg / L, Co=0.03-0.07mg / L, Ni=0.02-0.04mg / L;

[0024](2) Anaerobic treatment: the pre-treated oily wastewater enters the cooling tower 2 through the pump 5 and is cooled to 35°C-38°C, and then sent to the anaerobic reactor (UASB) 3 through the pump 5, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com