V shaped groove type microgrid component capable of continuously on-line updating dynamic membrane and use method thereof

A technology of dynamic membranes and cubes, applied in chemical instruments and methods, sustainable biological treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problems of high equipment idle rate, poor effect, difficult to increase water yield, etc., to achieve improved Membrane filtration area, reduction of manufacturing cost, and effect of device volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

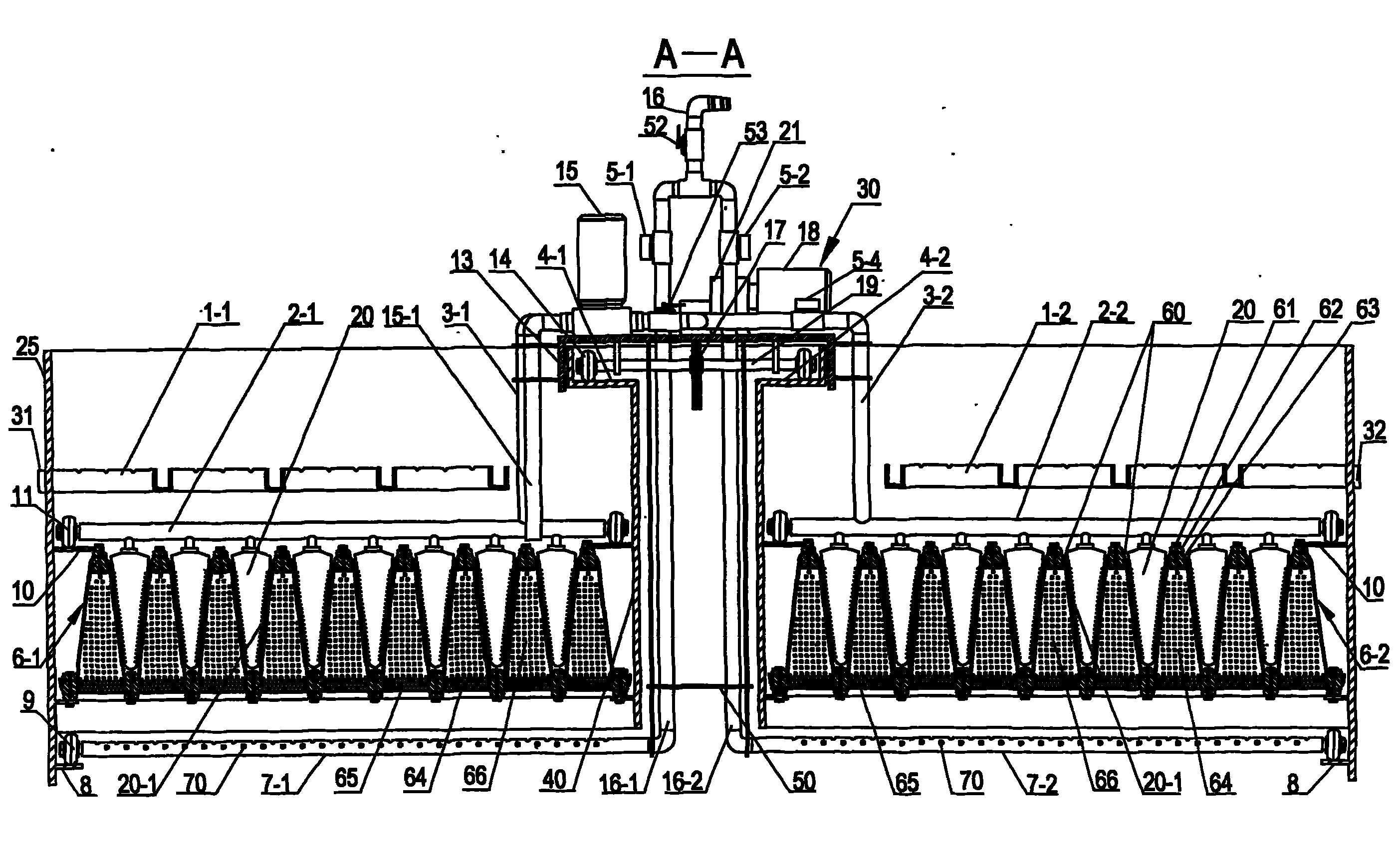

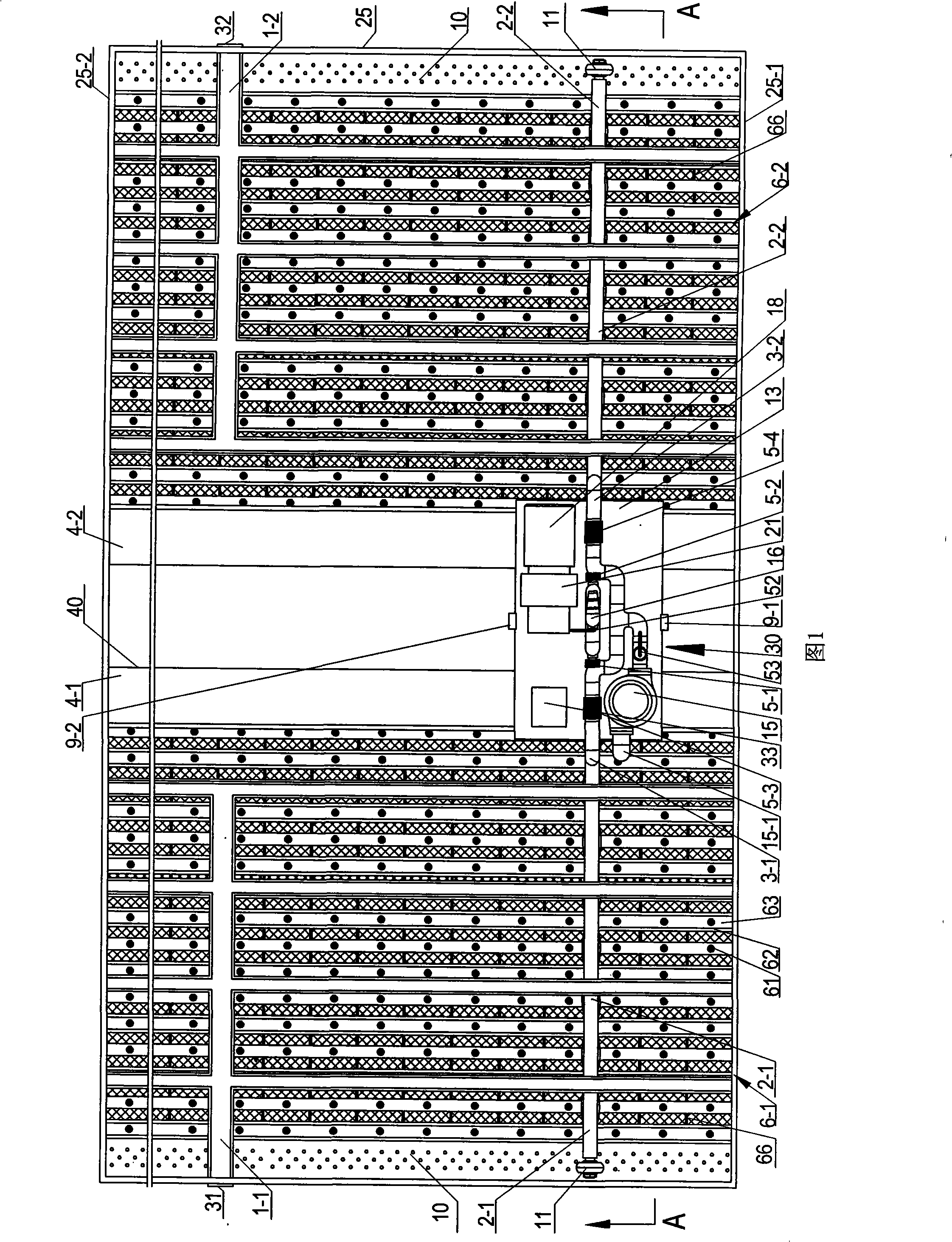

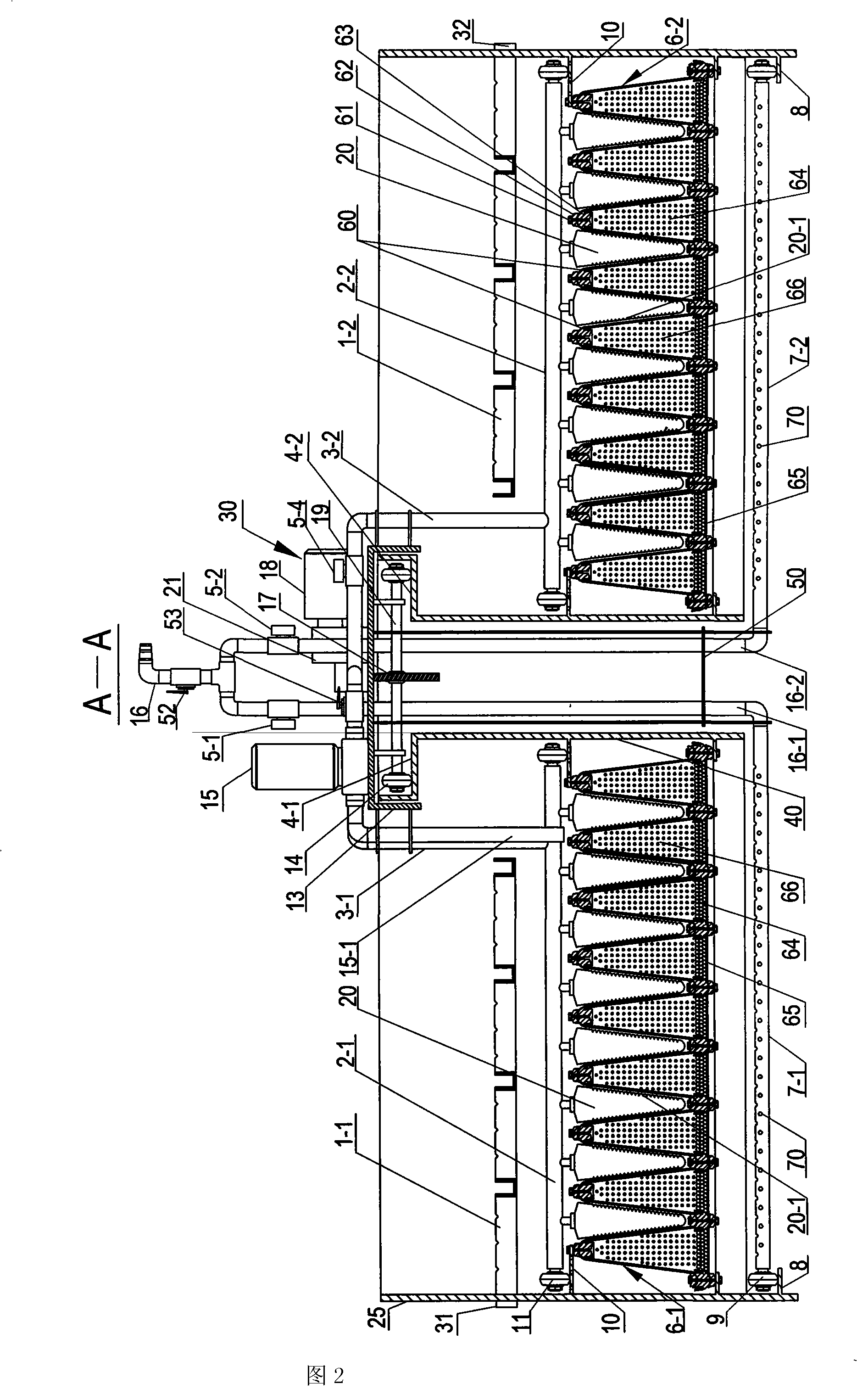

[0023] Fig. 1-Fig. 2 shows a kind of V-shaped groove type cubic micro-grid module that continuously updates dynamic film, comprises the micro-grid net body of supporting dynamic film, is characterized in that also is provided with box-shaped casing 25, T-shaped section guide rail 40. Backwashing water pipes 2-1, 2-2, jet flushing pipes 7-1, 7-2, water collection weirs 1-1, 1-2, running mechanism 30; 300-500-mesh micro-grids with different apertures are superimposed and fixed according to the skeleton to form a cubic micro-network body formed by connecting multiple rows of V-shaped grooves side by side. Some longitudinal strip-shaped closed mesh chambers formed between the V-shaped groove and the bottom net are separated into several segmented closed mesh chambers by a plurality of transverse partition orifice plates 66 arranged on the skeleton, and 2 ~3 layers of commercially available ceramsite balls 64 that can bounce under the upward thrust effect, the ceramsite balls are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com