Stapler

A stapler and staple technology, applied in binding and other directions, can solve problems such as danger and achieve the effect of reducing operating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

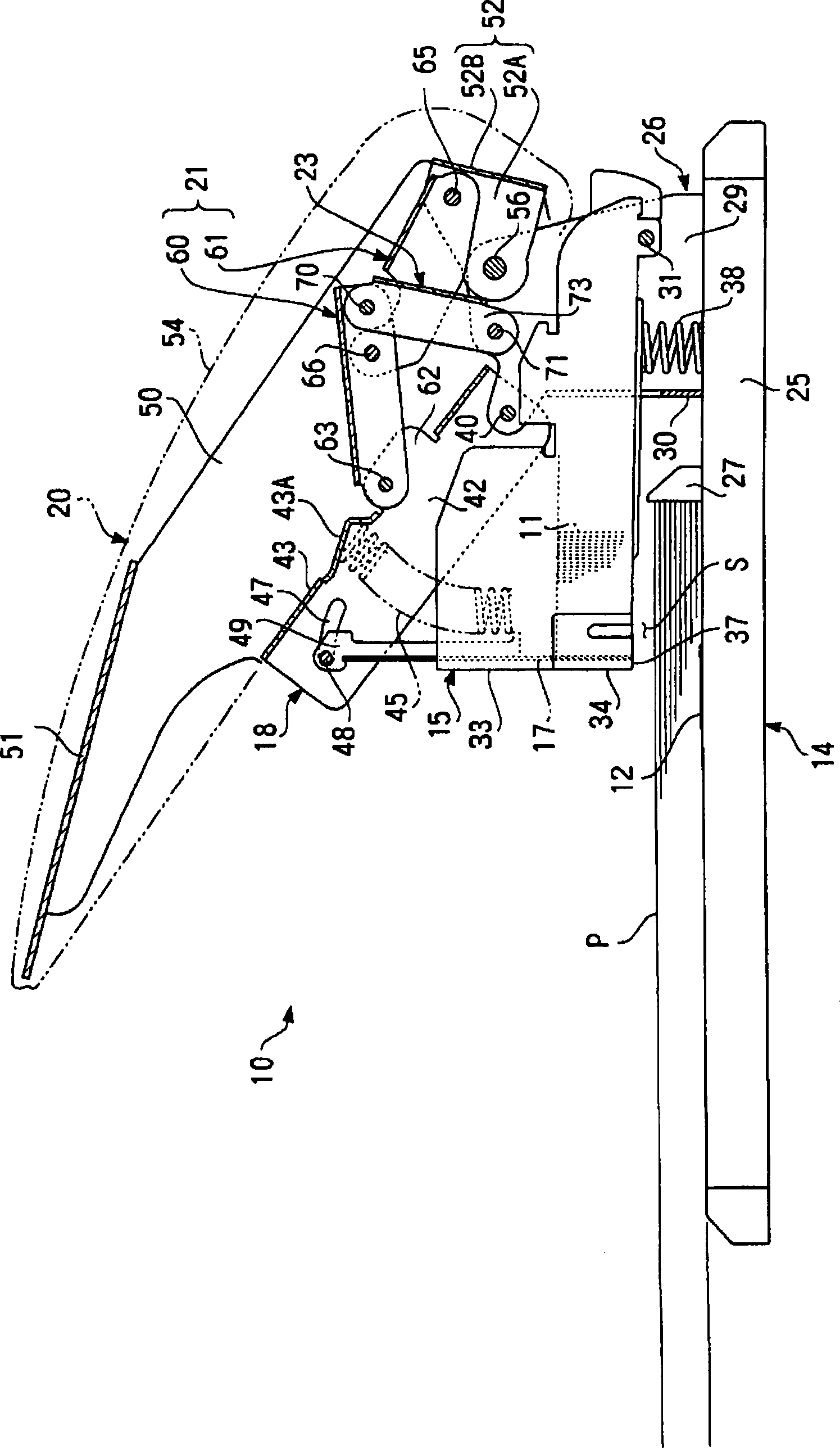

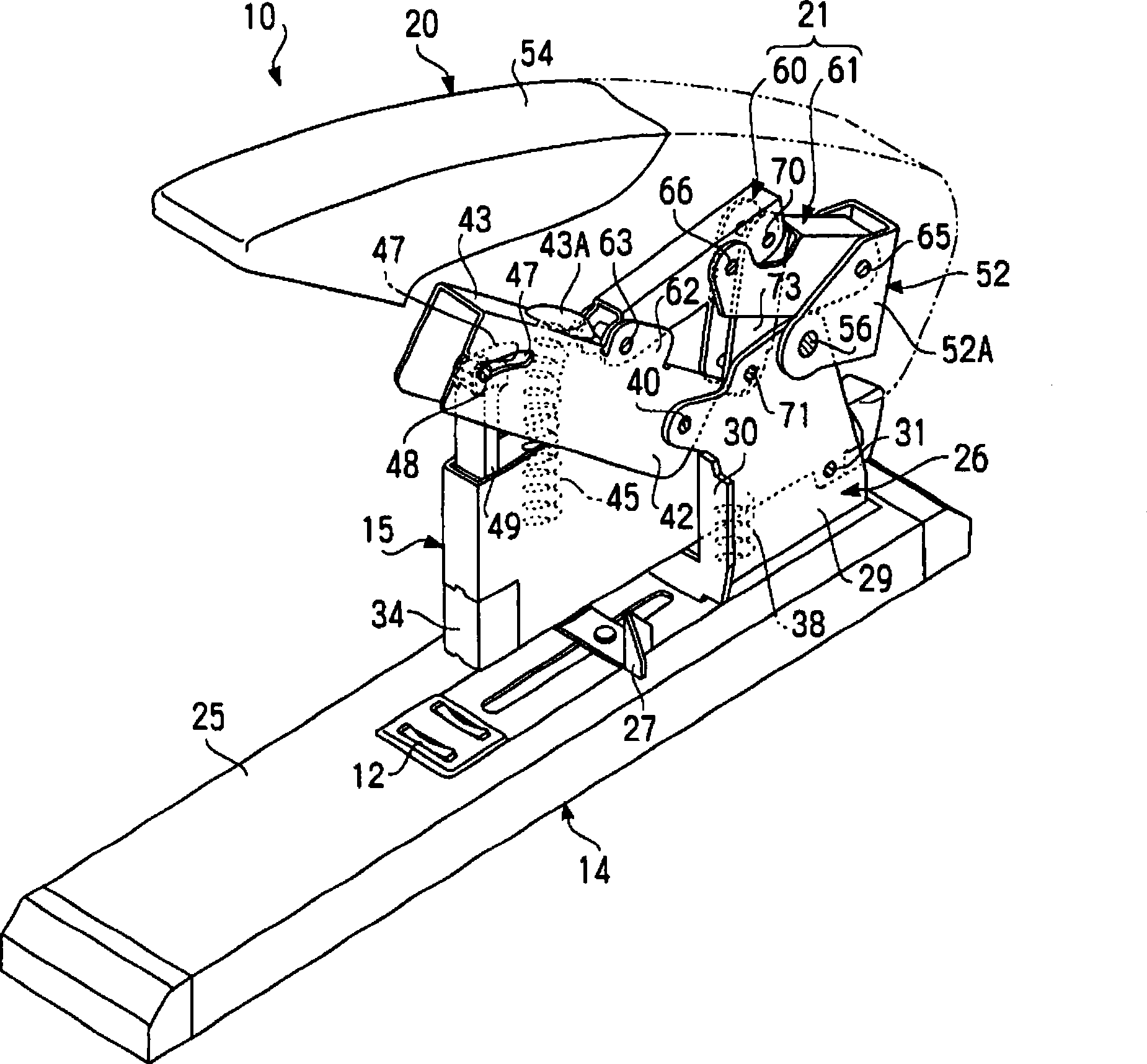

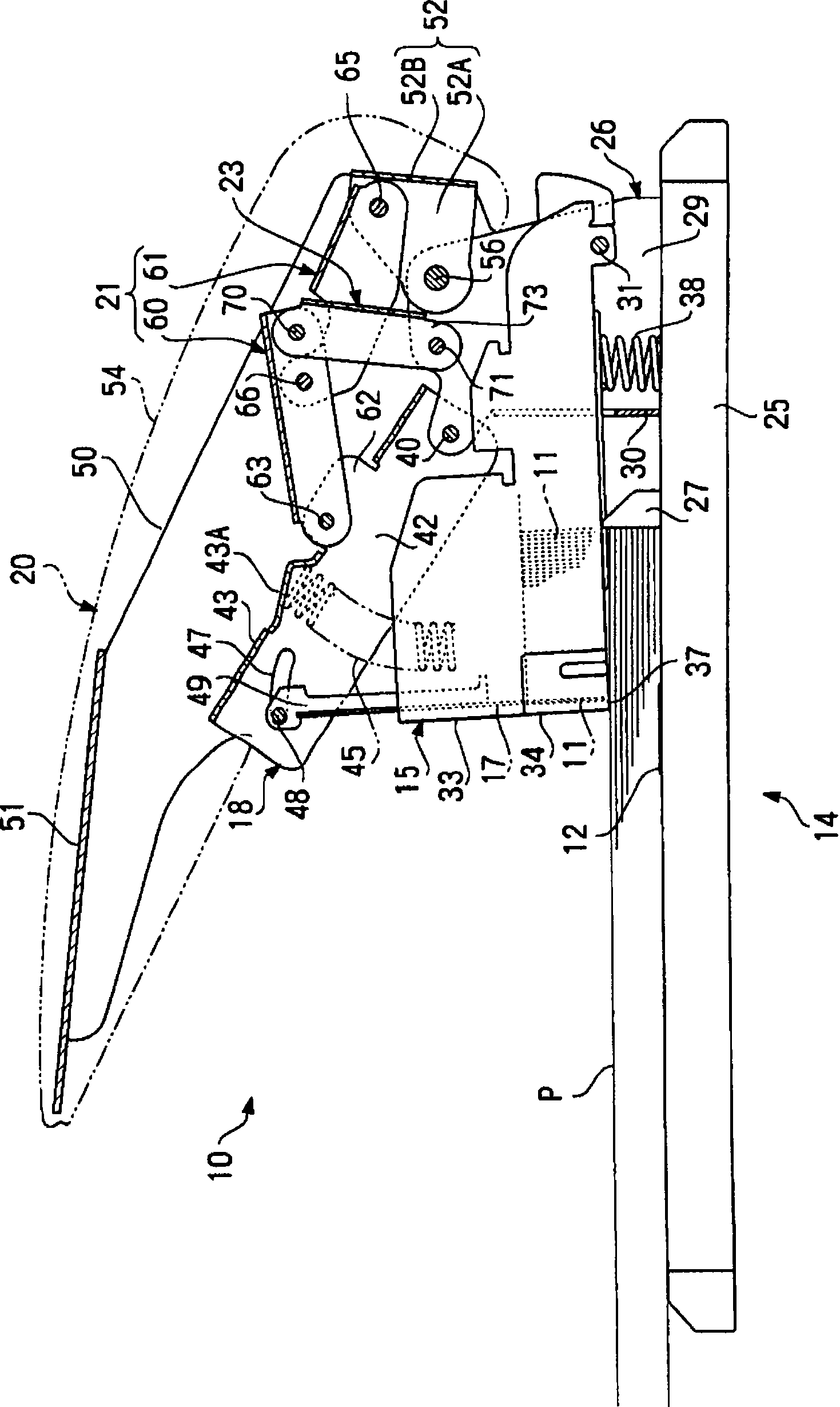

[0033] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, in this specification, terms indicating position or direction, unless otherwise specified, are referred to as figure 1 as the benchmark. Therefore, the so-called "former" is used to refer to figure 1 On the left side of the middle, the so-called "rear" is used to refer to the right side in the same figure.

[0034] exist figure 1 , shows a schematic side view of the stapler of this embodiment, in figure 2 , a schematic perspective view thereof is shown. In these figures, the stapler 10 is constituted as having: a base 14 having an anvil 12 for nailing the staple 11; Between 12, an insertion space S is formed as the paper P of the binding object; an intermediate member 18 is rotatably supported by a base 14 and has a pressing blade 17 for pressing the above-mentioned staple 11 to the anvil 12; a handle 20, Its one end side is rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com