Bearing ring digital control lathe clamper

A technology for CNC lathes and bearing rings, applied in the field of machine tool parts, can solve problems such as inconvenient disassembly and installation, increased replacement costs, and impact on production progress, and achieves time-saving and labor-saving disassembly and installation, maintenance and replacement cost savings, disassembly and installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

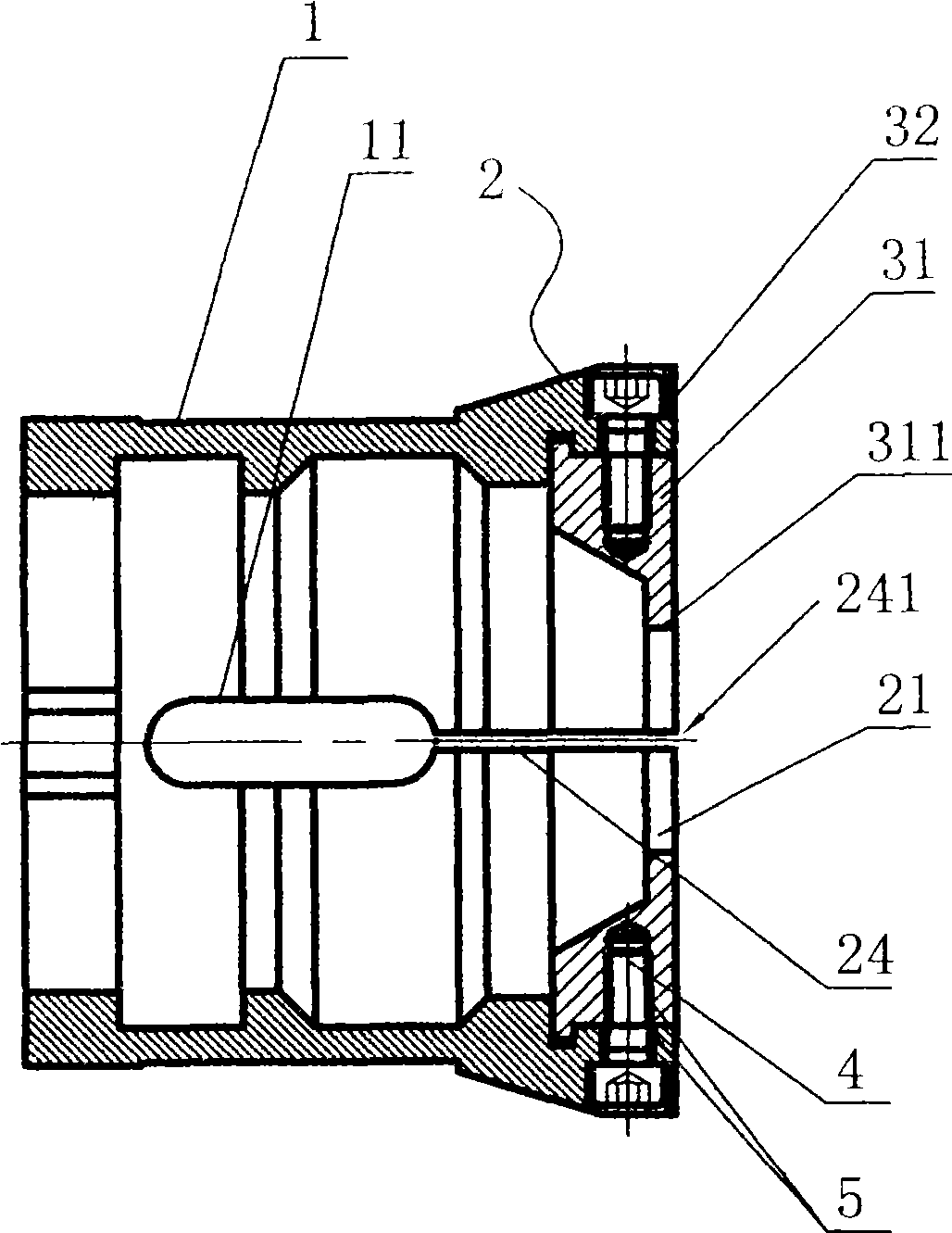

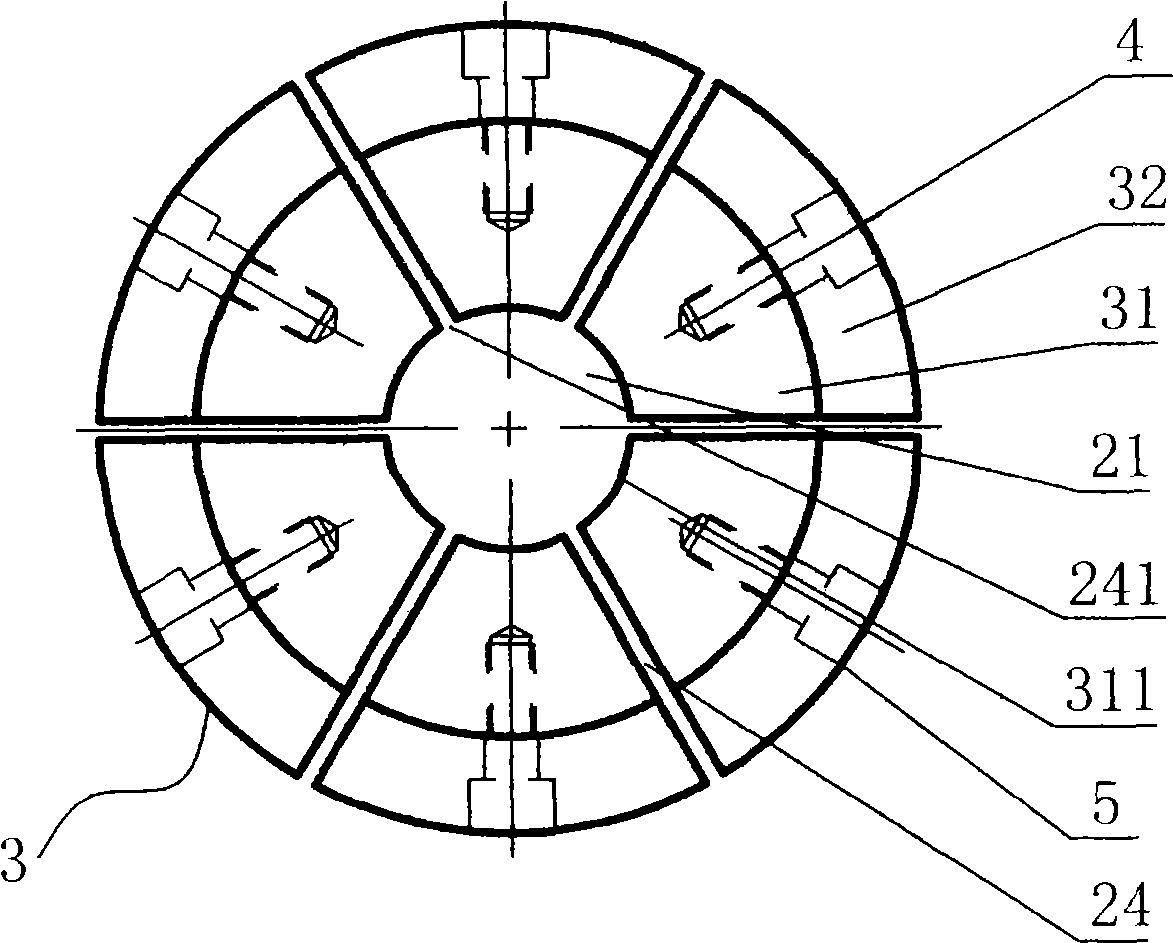

[0014] Such as figure 1 , figure 2 As shown, a fixture for a bearing ring CNC lathe, the fixture includes a base 1 fitted on one end of the lathe spindle, six waist-shaped through holes 11 are evenly distributed on the side of the base 1, and the end surface of the base 1 is fixed with an inner hole 21. Conical collet 2, this collet 2 is made up of six fan-shaped blocks 3, the gap between each fan-shaped block 3 forms elongated groove 24, and this elongated groove 24 is connected with waist-shaped through hole 11, and each fan-shaped block 3 is spliced by inner and outer sector blocks 31,32, and the inner circular arc 311 of each inner sector block 31 forms an inner hole 21 with a notch 241, and the inner and outer sector blocks 31,32 are connected by bolts 4.

[0015] The cross-sectional shape of the waist-shaped through hole 11 is such that the ends of the shorter sides of the rectangle are connected to the corresponding ends of a semicircular arc, and the long side dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com