Centrifugal subsidence mixed dirt remover

A centrifugal sedimentation and mixing technology, which is applied in the direction of the swirling device and the swirling device in which the axial direction of the swirl can be reversed, can solve the problems of difficult removal of impurities, low decontamination efficiency of the decontamination device, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

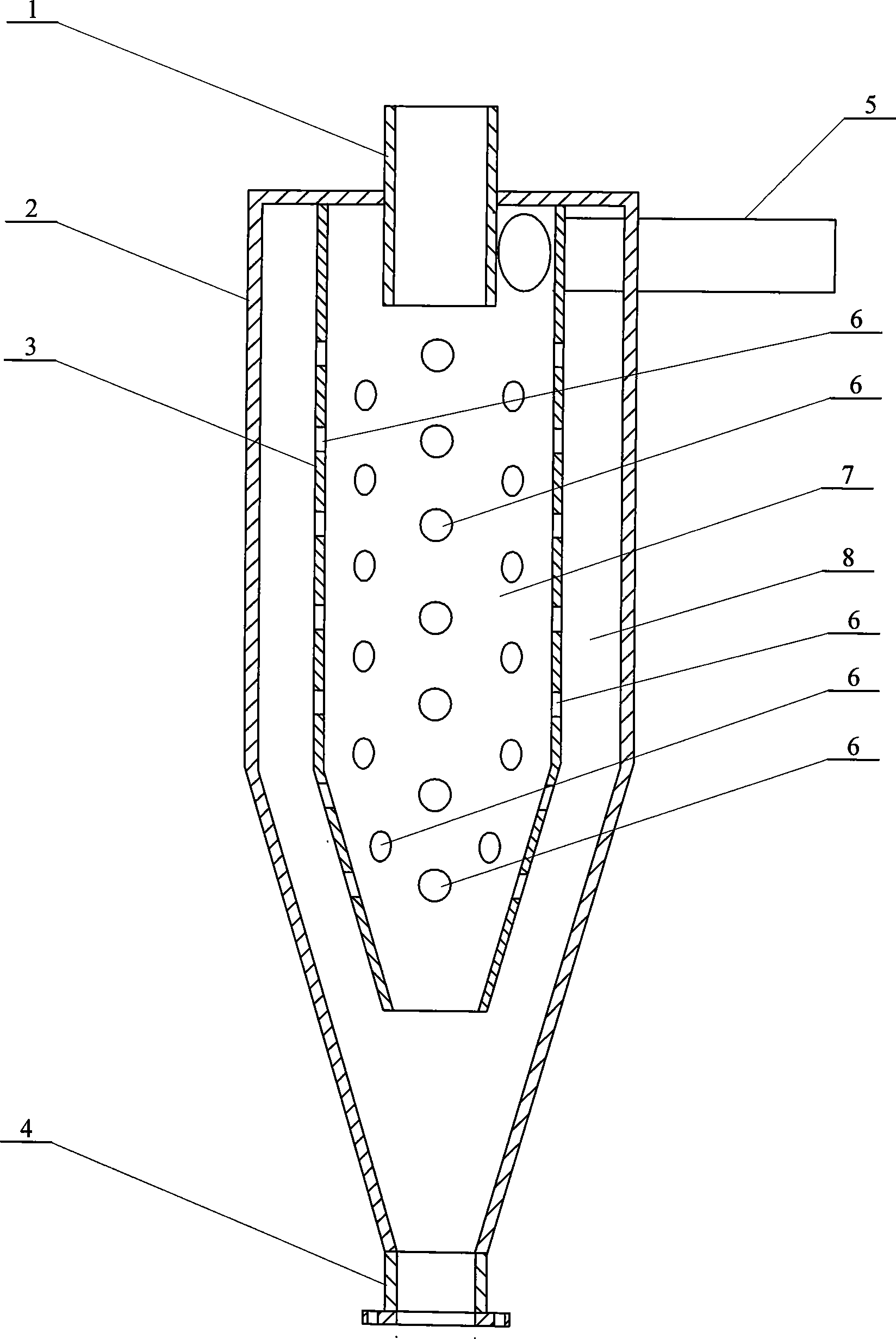

[0006] Specific implementation methods: (see figure 1 and figure 2 ) This embodiment consists of a water outlet pipe 1, an outer cylinder 2, an inner cylinder 3, a dirt discharge pipe 4 and a water inlet pipe 5. The dirt discharge pipe 4 communicates with the lower end of the outer cylinder 2. The top is connected, the inner cylinder 3 is set in the outer cylinder 2, the inner cylinder 3 is coaxial with the outer cylinder 2, the upper end of the inner cylinder 3 is fixedly connected with the inner wall of the top cover of the outer cylinder 2, and a through hole is opened on the wall of the inner cylinder 3 6. The inner space of the inner cylinder 3 is the swirl zone 7, the space between the inner cylinder 3 and the outer cylinder 2 is the settlement zone 8, one end of the water inlet pipe 5 is connected to the upper side wall of the inner cylinder 3, and the water inlet pipe 5 is cut It enters the inner cylinder 3 and communicates with the swirl zone 7 inside the inner cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com