Energy type mixed feed instead of corn and method for producing the same

A mixed feed and energy-based technology, applied in animal feed, animal feed, application, etc., can solve the problems of spilling on the fields, on both sides of the road, shortage of corn resources, and environmental pollution, so as to reduce feed cost, reasonable composition, The effect of increasing the sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

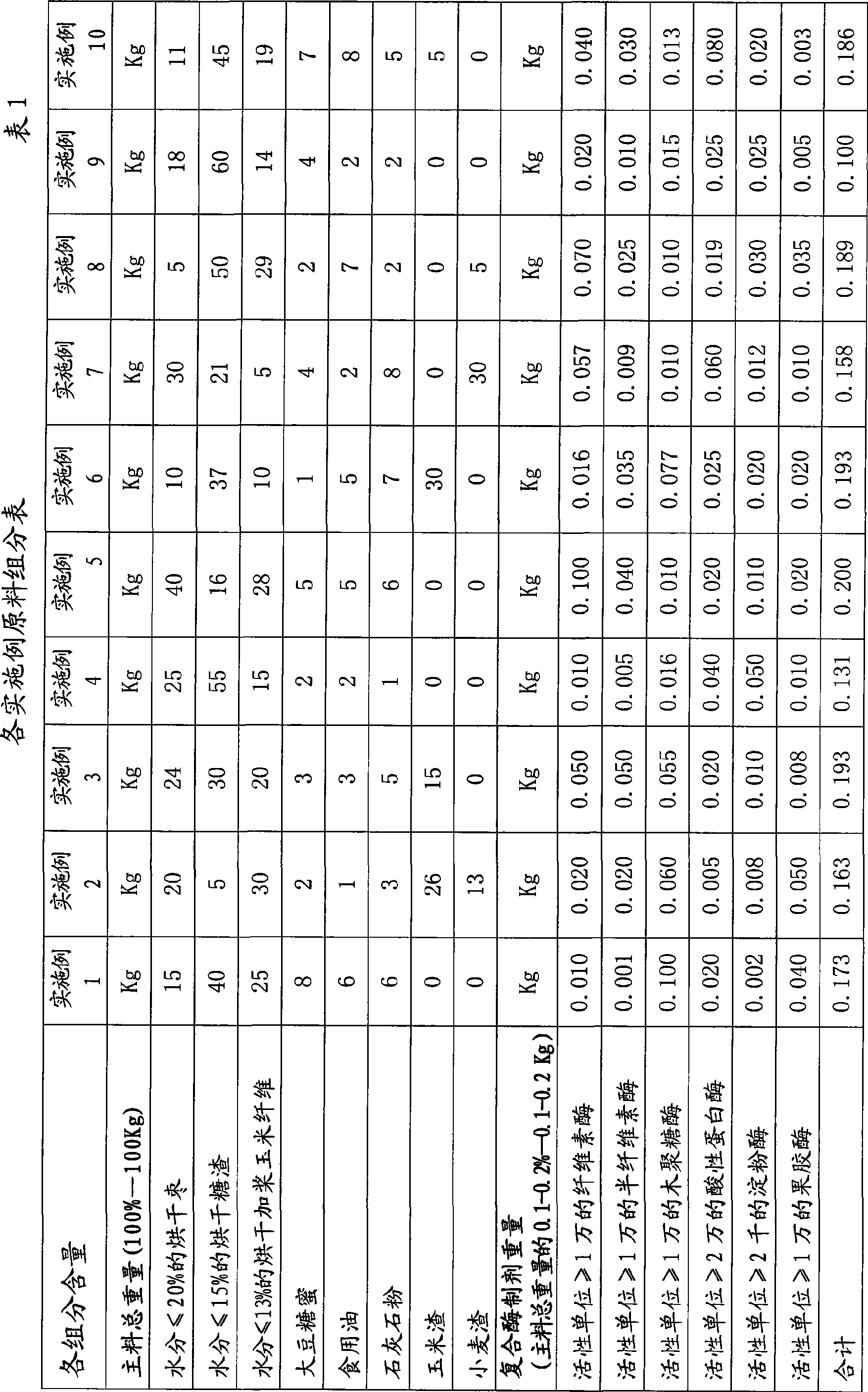

[0033] 1. The content of each component of the main ingredient and the compound enzyme preparation in the energy type mixed feed batching instead of corn, according to the total weight of the main ingredient 100Kg is 100%, the weight of the compound enzyme preparation added is 0.1-100% of the total weight of the main ingredient 0.2%, that is, 0.1-0.2Kg, as shown in the data of Example 1 in Table 1.

[0034] 2. The manufacturing steps are as follows:

[0035] (1). The above-mentioned components of the composite enzyme preparation and the limestone powder in the main ingredient are weighed according to the content of each component in Table 1 and put into a mixer for uniform mixing until the coefficient of variation is ≤ 5, and the composite enzyme is obtained. premix.

[0036]

[0037] (2). Weigh the dried jujube, dried sugar slag, and dried paddle corn fiber according to the content of each component in Table 1 and put them into a pulverizer. The soybean molasses, edible ...

Embodiment 2

[0039] 1. The content of each component of the main ingredient and the compound enzyme preparation in the energy type mixed feed batching instead of corn, according to the total weight of the main ingredient 100Kg is 100%, the weight of the compound enzyme preparation added is 0.1-100% of the total weight of the main ingredient 0.2%, i.e. 0.1-0.2Kg, as shown in the data of Example 2 of Table 1, compared with Example 1, the main ingredients of this example have increased corn dregs and wheat dregs, which can further reduce feed costs while ensuring nutritional components .

[0040] 2. The manufacturing steps are as follows:

[0041] (1). With embodiment 1;

[0042] (2). Weigh the dried jujube, dried sugar slag, dried paddle corn fiber, corn dregs and wheat dregs according to the content of each component in Table 1 and put them into a grinder, and grind them to 20-80 mesh , and put into the mixer evenly mixed with soybean molasses, edible oil and compound enzyme premix prepar...

Embodiment 3

[0044]1. The content of each component of the main ingredient and the compound enzyme preparation in the energy type mixed feed batching instead of corn, according to the total weight of the main ingredient 100Kg is 100%, the weight of the compound enzyme preparation added is 0.1-100% of the total weight of the main ingredient 0.2%, i.e. 0.1-0.2Kg, as shown in the data of embodiment 3 of table 1, compared with embodiment 1, the main ingredient of this example has increased corn dregs, which can further reduce the feed cost while ensuring nutrition.

[0045] 2. The manufacturing steps are as follows:

[0046] (1). With embodiment 1;

[0047] (2). Weigh the dried jujube, dried sugar slag, dried paddle corn fiber, and corn dregs according to the content of each component in Table 1 and put them into a pulverizer. The soybean molasses, edible oil and compound enzyme premix prepared by step (1) weighed according to the content of each component in Table 1 are put into a mixer and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com