Structured OLED with micro optics for generating directed light

A lighting equipment and optical collimation technology, which is applied in the directions of optics, nonlinear optics, electroluminescent light source, etc., can solve the problems of expensive and complicated manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

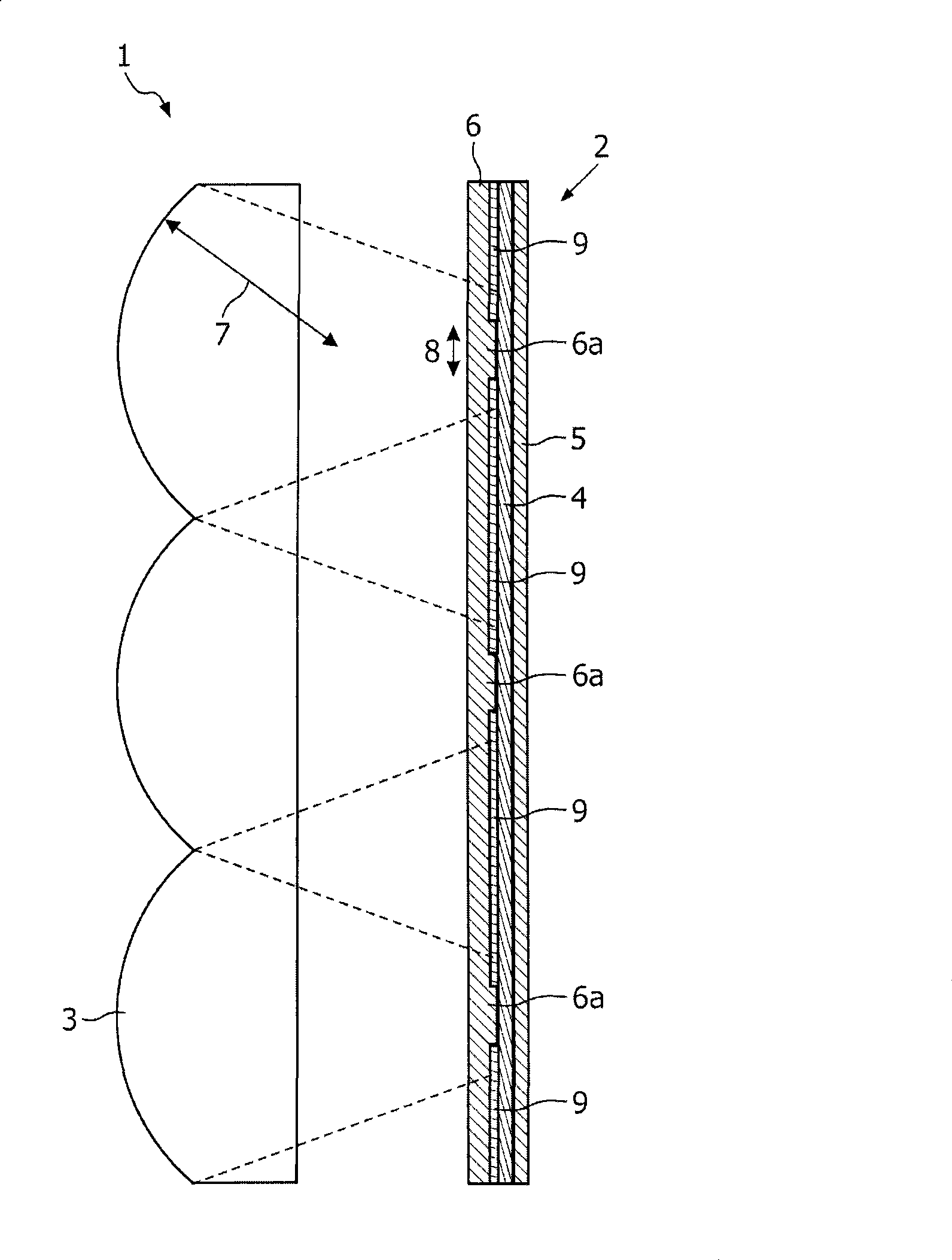

[0030] refer to figure 1 , the lighting device 1 is formed by a stacked OLED 2 and a collimating lens array 3 . The lens array 3 is made of PMMA (polymethylmethacrylate), which is transparent in the visible wavelength range. Each single lens of the lens array 3 exhibits an acceptance angle such as figure 1 Indicated by the dotted line.

[0031] Separated from the lens array 3, the OLED stack 2 is arranged within a prescribed proximity. The OLED stack 2 comprises at least an OLED layer 4 and a first continuous electrode layer 5 arranged on the back side of the OLED layer 4 . A second electrode layer 6 is provided on the front side of the OLED layer 4 .

[0032] The second electrode layer 6 is continuous but is in contact with the OLED layer 4 only in sections 6 a which are within the acceptance angle of the lenses of the lens array 3 . Between these sections there is an insulating layer 9 . For this reason, the generation of light in the OLED layer 4 is only stimulated wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com