Plasma deposition apparatus and method for making solar cells

A solar cell, plasma deposition technology, applied to circuits, electrical components, coatings, etc., to achieve high built-in potential, eliminate two-step process, and high throughput rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

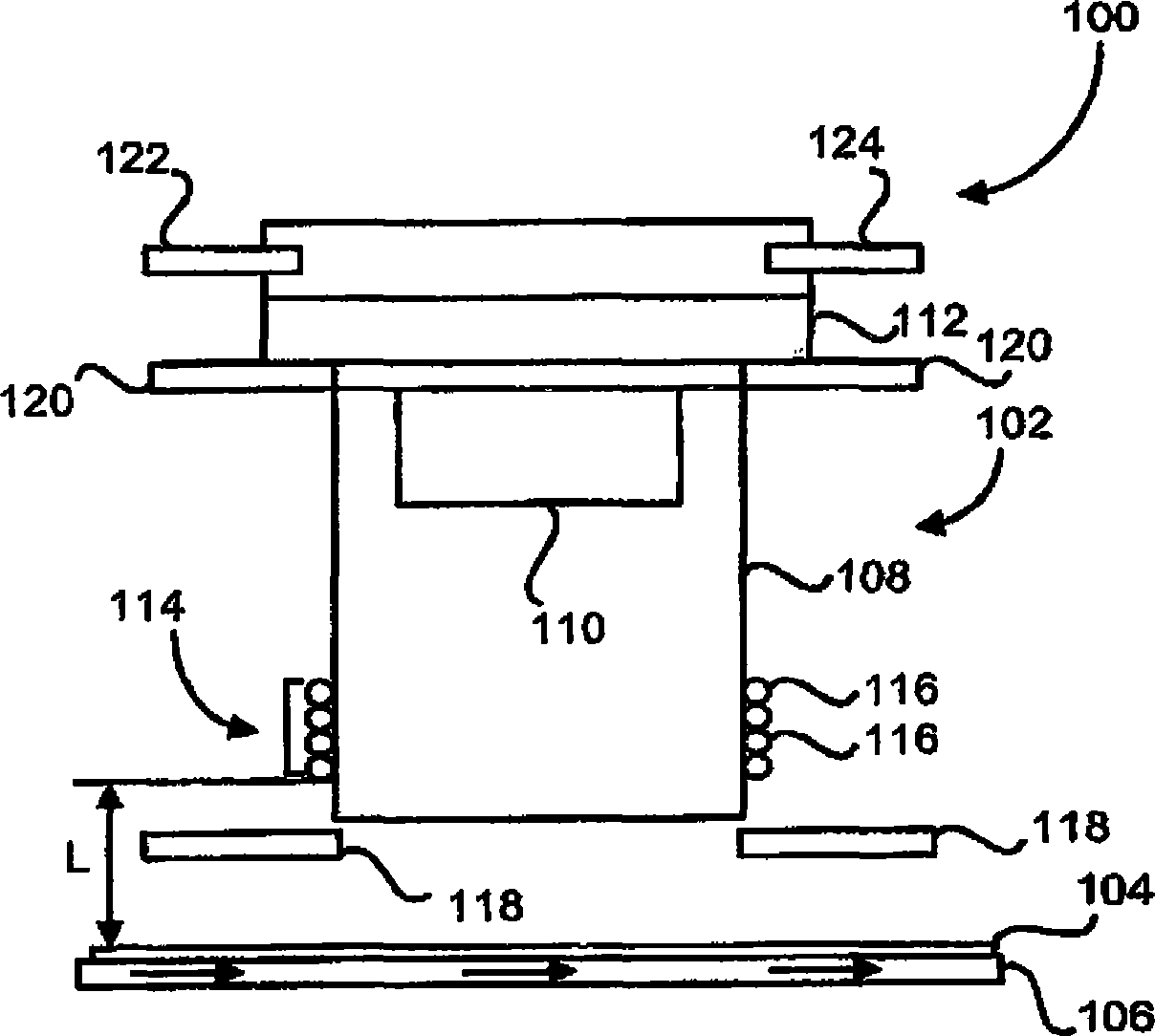

[0030] figure 1 An embodiment 100 of a plasma deposition apparatus including an inductively coupled plasma torch 102 positioned above a substrate 104 supported on a conveyor 106 is shown. In this embodiment, inductively coupled plasma torch 102 is aimed downward to deposit reaction products on substrate 104 . In another embodiment, the ICP torch 102 may be aimed or oriented in another manner or direction relative to the substrate 104 . The inductively coupled plasma torch 102 consists of two quartz tubes: an outer quartz tube 108 and a shorter inner quartz tube 110 , which are shown attached to a stainless steel chamber 112 .

[0031] Conveyor 106 has a definition as with image 3 The longitudinal axis parallel to the direction of the arrow shown in . Conveyor 106 may be a fixed platform or a moving conveyor. Preferably, it provides support for one or several substrates 104 and presents these substrates to the ICP torch 102 at a desired distance depending on the ICP torch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com