Air valve pressing mechanism capable of precisely controlling different air valve angle shift-down

A technology of precise control and pressing mechanism, applied in the direction of internal combustion engine test, engine test, machine/structural component test, etc., can solve the problems of difficult displacement control, difficult to fix displacement sensor, complex structure, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

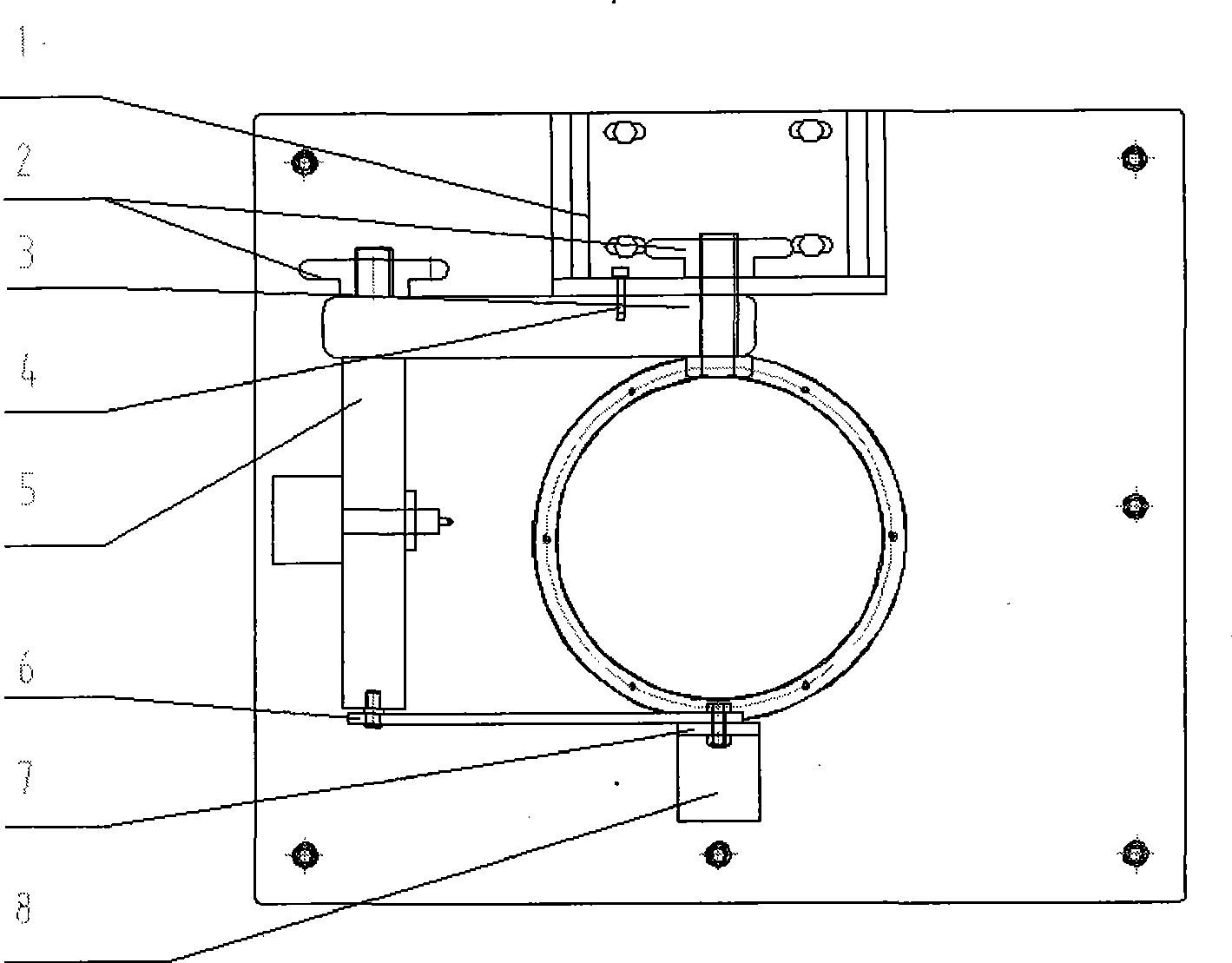

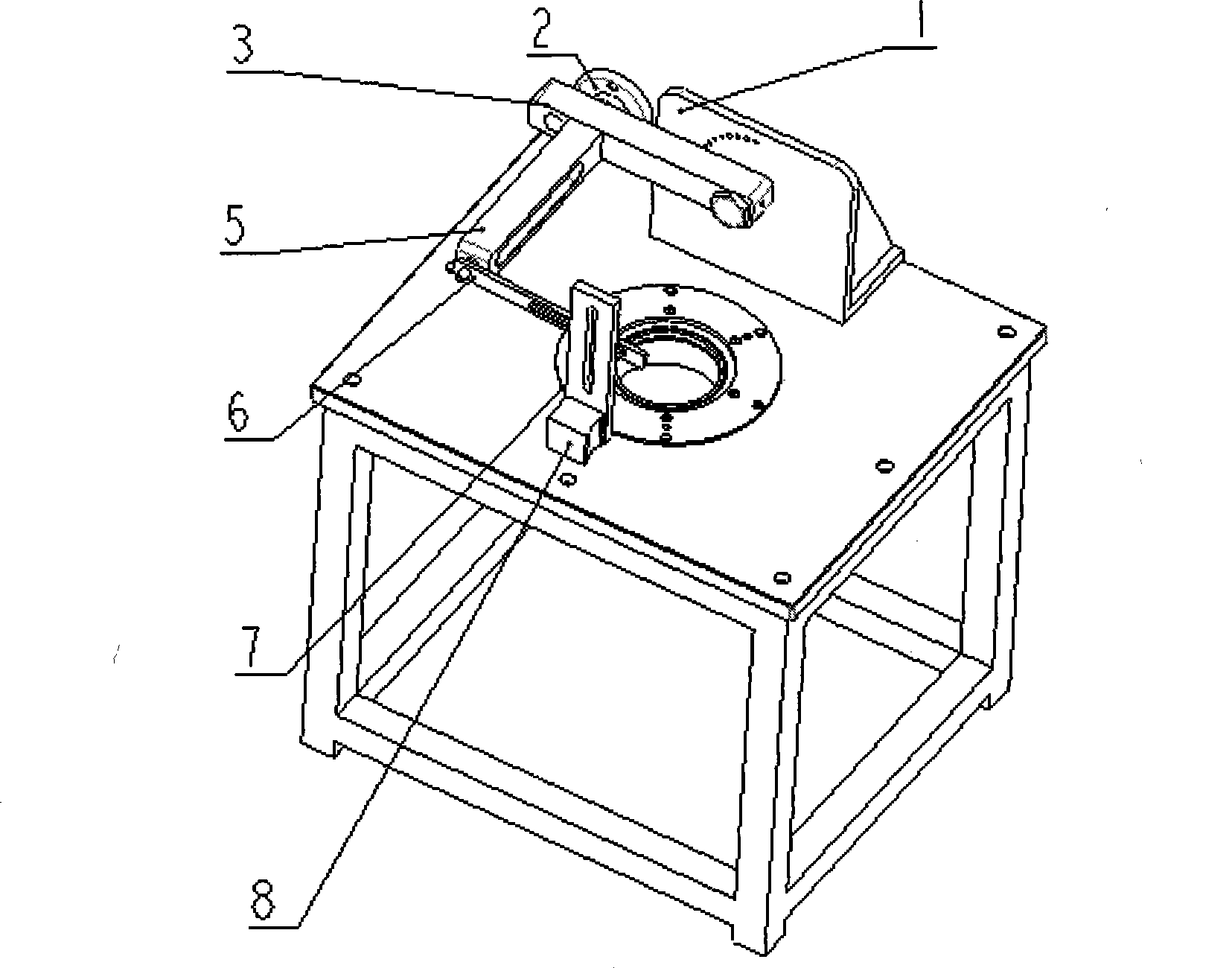

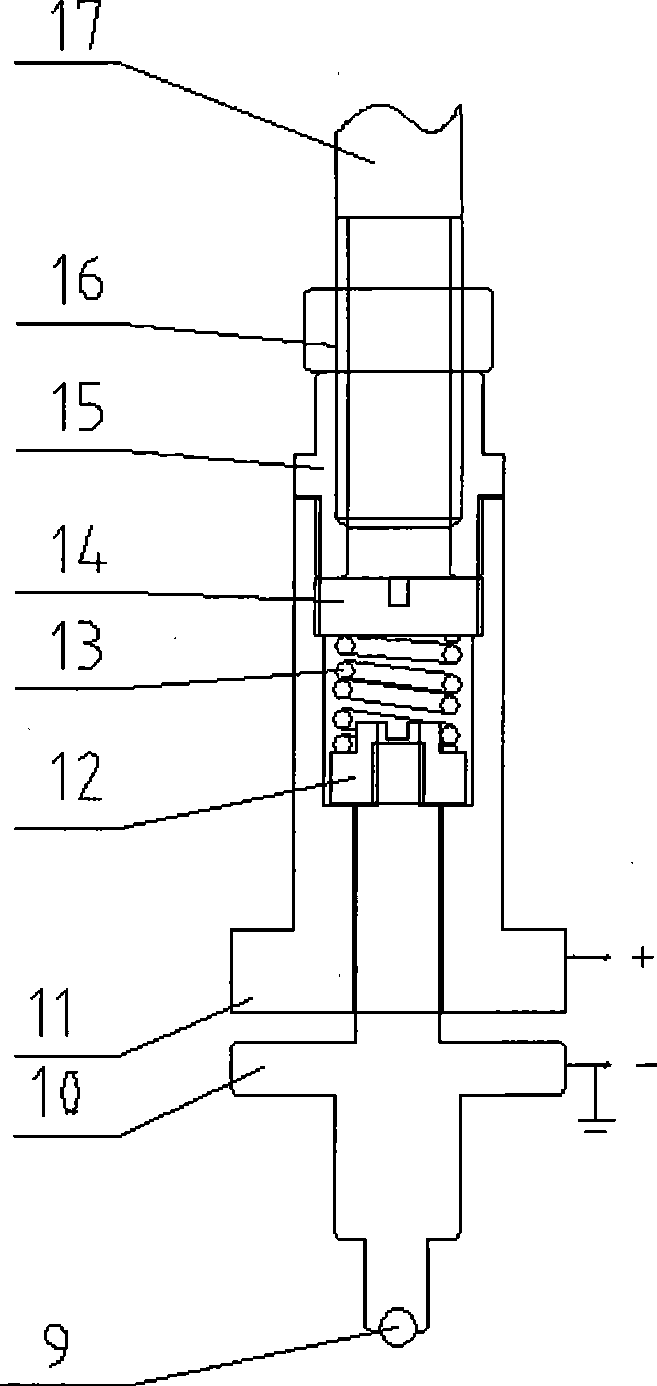

[0013] Embodiment: The cylinder head of the internal combustion engine is placed on the airway test bench, and the vertical arm 3 and the cross arm 5 are rotated and adjusted so that the spherical indenter 9 can be vertically pressed into the valve, and then the vertical arm and the vertical plate shaft are fixed with bolts and locking wheels , and at the same time use the positioning pin 4 to place the small hole on the vertical plate 1 ( image 3 ) is connected with the arc groove on the vertical arm. The linear motor is controlled by a computer. When the detection assembly presses the valve downward through the extension shaft of the linear motor, the spherical pressure head 9 remains stationary due to the certain rigidity of the valve spring in the cylinder head of the internal combustion engine, so the upper end surface of the connector is also Keep it still, and the detection piece moves downward. When the spring 13 in the detection assembly is fully compressed, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com