Preparation of conductive polymer / inorganic nano composite electrode modified material

A kind of electrode modification and nanotechnology, which is applied in the field of preparation of conductive polymer/inorganic nanocomposite electrode modification materials, can solve the problems of difficult cleaning of modified electrodes, and achieve the effect of simplifying the electrode processing process, good monodispersity and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A. In a 250mL Erlenmeyer flask, 0.0667g of a PAA aqueous solution with a solid content of 30wt% was added to 200mL of distilled water to configure a concentration of 0.1mg / mL PAA aqueous solution.

[0080] B. In a 50mL Erlenmeyer flask, add 0.142g EDOT monomer, 0.1093g CTAB, and 8mL, 0.1mg / mL PAA aqueous solution into 24mL distilled water, and stir magnetically at room temperature for 1 hour until the solution is completely clear.

[0081] C. Take another 50mL conical flask, put 0.81g FeCl 3 ·6H 2 O was dissolved in 8 mL of distilled water.

[0082] D. Add the solution obtained in step C to the solution obtained in step B, stir evenly, then transfer to a constant temperature water bath at 50°C and let it stand for reaction for 20 hours.

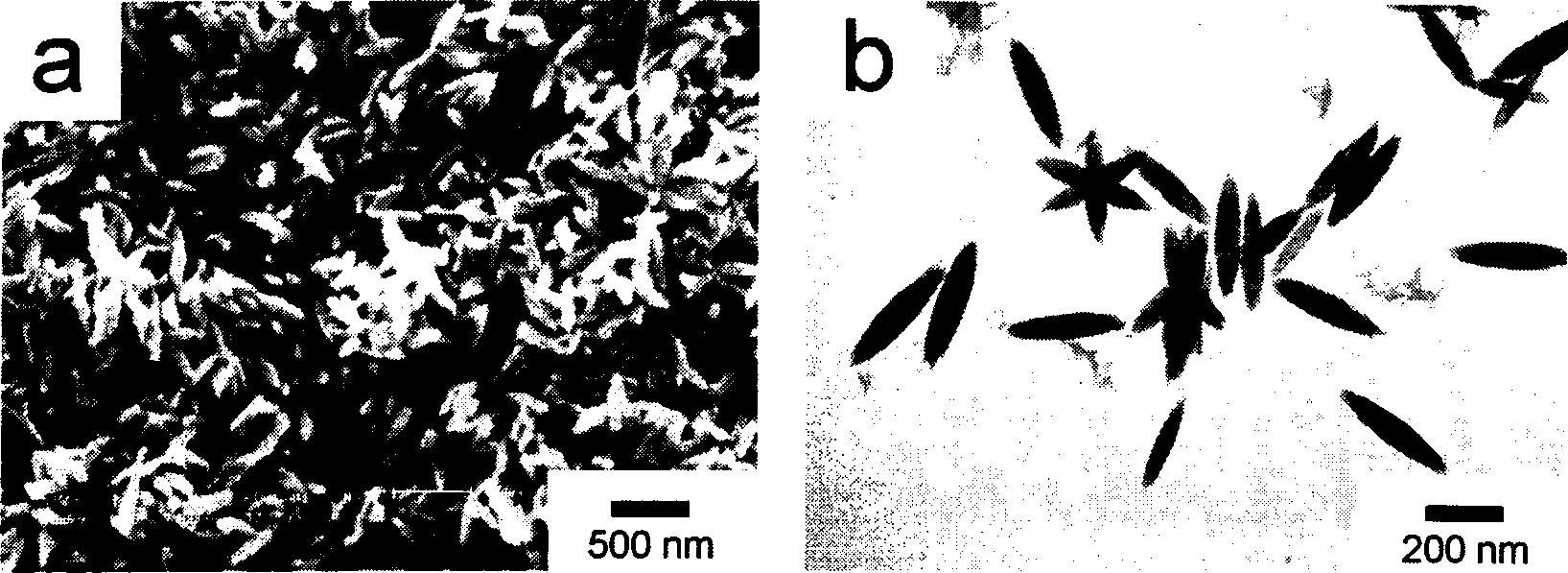

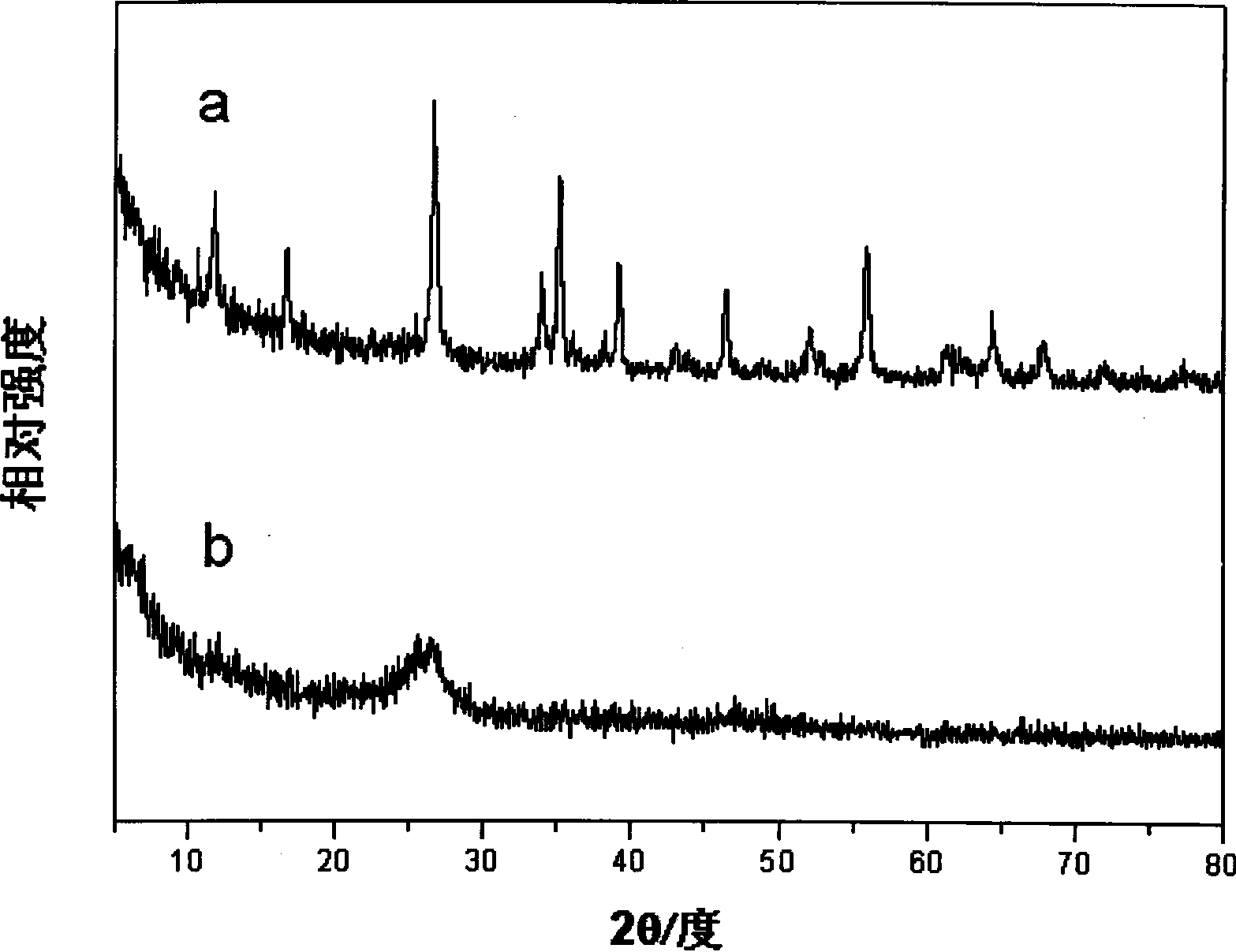

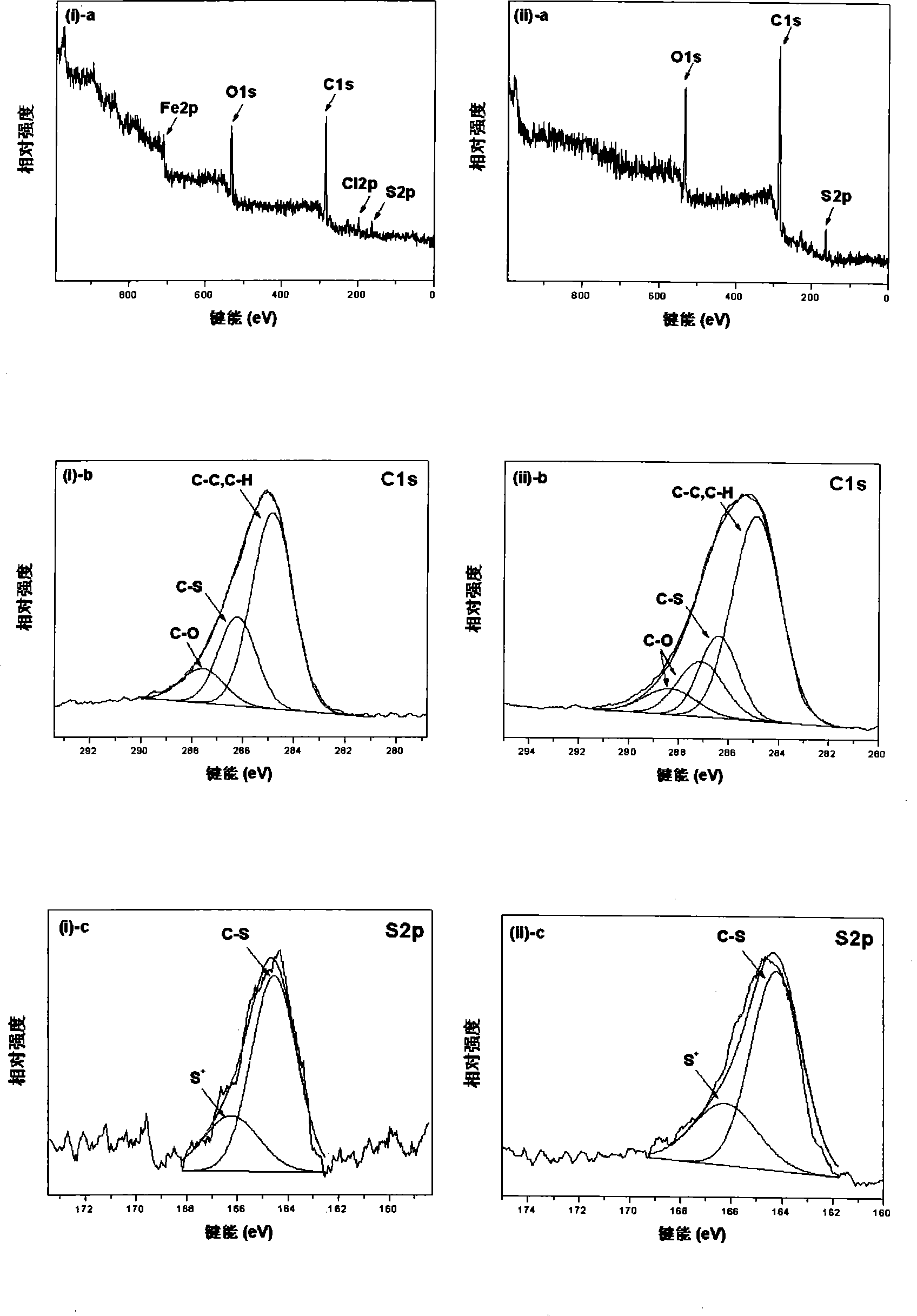

[0083] After the reaction was completed, the obtained dark blue flocculent precipitate was collected by centrifugation, washed several times with distilled water and ethanol to remove surfactant (CTAB) and by-products with lower mole...

Embodiment 2

[0085] Ultrasonic dispersion of the electrode modification material obtained in Example 1 into 7mL of ethanol, configured to a concentration of 3.45mg / mL PEDOT / β-Fe 3+ Ethanol dispersion of O(OH,Cl) nanospindles. Use a sample gun to take 6 μL of the above dispersion solution and drop it on the surface of the polished glassy carbon electrode. After the ethanol is completely evaporated at room temperature, PEDOT / β-Fe 3+ O(OH,Cl) nanospindle modified electrodes.

[0086] Configure 0.1M HClO 4 Aqueous solution, and 0.1M HClO with KI concentration of 0.1mM, 1mM, 10mM 4 Aqueous solution, CV test.

[0087] Such as Figure 8 As shown, compared with the polished but unmodified glassy carbon electrode, the obtained PEDOT / β-Fe 3+ O(OH,Cl) nanospindle modified electrode in 0.1M HClO 4 The response current in aqueous solution increases significantly, and has a good electrocatalytic response to KI, the current increases, and the peak position changes ( Figure 9 ). Such as Figure ...

Embodiment 3

[0089] Same as the method for preparing the modified electrode in Example 2, obtain PEDOT / β-Fe 3+ O(OH,Cl) nanospindle modified electrodes. Configure 0.1M HClO 4 Aqueous solution, and KIO3 concentration of 0.1mM, 1mM, 10mM 0.1M HClO 4 Aqueous solution, CV test.

[0090] Such as Figure 12 As shown, compared with the polished but unmodified glassy carbon electrode, the obtained PEDOT / β-Fe 3+ O(OH,Cl) nanospindle modified electrode in 0.1M HClO 4 KIO in aqueous solution 3 It has a good electrocatalytic response, the current increases, and the peak position changes ( Figure 13 ). Such as Figure 10 As shown, the prepared PEDOT / β-Fe 3+ O(OH, Cl) nanospindle-modified electrodes containing different concentrations of KIO 3 0.1M HClO 4 CV curves in aqueous solution: (a) 0, (b) 0.1, (c) 1, (d) 10 mM. It can be seen that the response current increases with the increase of KI concentration. Such as Figure 14 As shown, the prepared PEDOT / β-Fe 3+ O(OH,Cl) nanospindle mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com