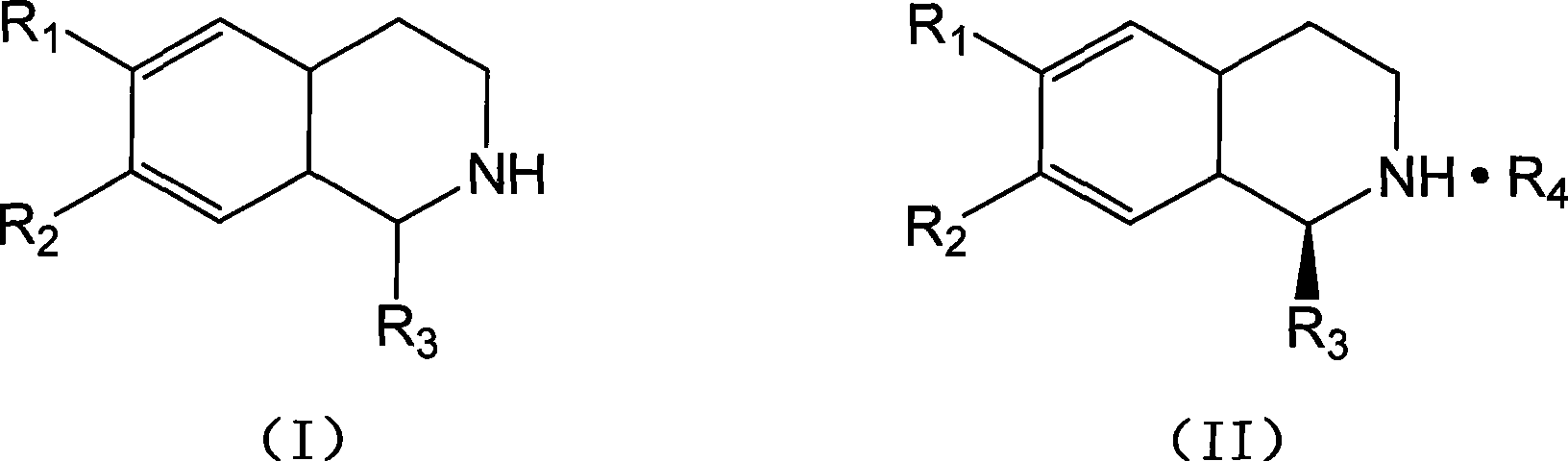

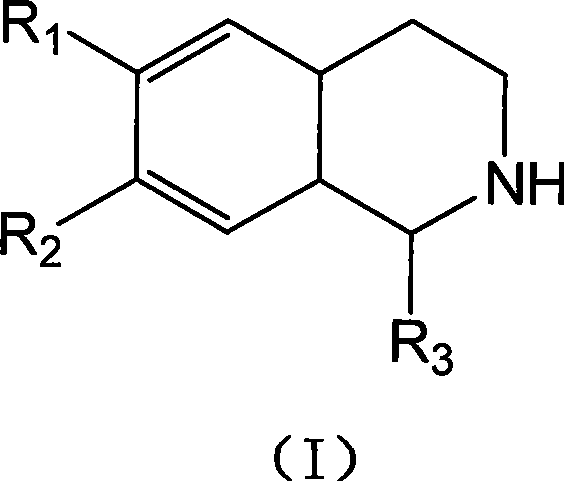

Mixed solvent crystallization resolution method for tetrahydrochysene isoquinoline racemate

A technology of tetrahydroisoquinoline and racemate, which is applied in the direction of organic chemistry, can solve the problems of complex operation, unfavorable industrial scale-up, and long splitting time, so as to simplify the operation process, simplify equipment, and shorten the splitting time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

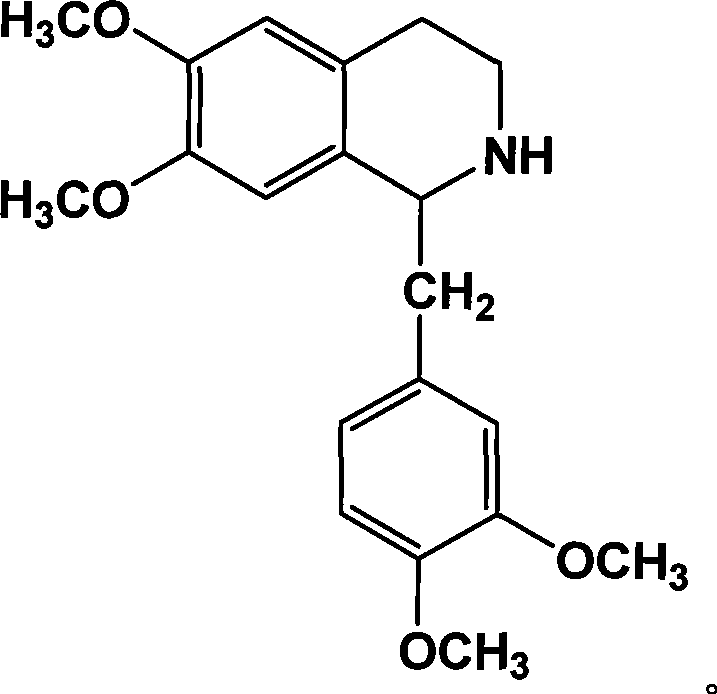

Embodiment 1

[0039] Example 1: Add 500 g of tetrahydropapaverine oil, 10 L of methanol, and 250 g of N-acetyl-L leucine into a 20 L glass reactor, start stirring, heat to 60 ° C, and react for 40 to 60 minutes. After the end, the temperature was lowered, and the reaction solution was added into a 50L glass reactor with 40L ether, stirred, and a white solid was precipitated, filtered, and dried to obtain 250 g of R-type tetrahydroisoquinoline salt crude product.

[0040] 5L of methanol dissolves the above-mentioned crude product, and after dissolving, it is added into a 50L glass reactor with 20L of ether, stirred, and a white solid is precipitated, filtered, and dried to obtain 110g of R-type tetrahydroisoquinoline salt, and the HPLC detection R% content is greater than 95%, yield 30%.

Embodiment 2

[0041] Embodiment 2: substantially identical with embodiment 1, but wherein the polar solvent described in (1) step uses acetone instead; Polar solvent: tetrahydroisoquinoline racemate=1:60. The non-polar solvent is changed to petroleum ether; polar solvent / non-polar solvent=1:25. The ratio of tetrahydroisoquinoline racemate to resolving agent adopts a molar ratio of 1:1.

Embodiment 3

[0042] Embodiment 3: substantially the same as Example 1, but wherein the polar solvent described in (1) step uses ethanol instead; Polar solvent: Tetrahydroisoquinoline racemate=1:10; Resolving agent Use N-acetyl-D-leucine instead; use isopropyl ether as the non-polar solvent; polar solvent / non-polar solvent=1:10. The ratio of the tetrahydroisoquinoline racemate to the resolving agent is a molar ratio of 1:1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com