Multifunctional bundling machine for multi-layer bundling of metal pressure container

A pressure vessel and wrapping machine technology, which is applied in the field of wrapping machines, welding, and multi-layer steel sheet wrapping, can solve problems such as start-up, stop and operation instability, failure to achieve clamping effect, inconvenient inspection and maintenance, etc., to facilitate inspection and maintenance. Maintenance, saving lifting auxiliary equipment and man-hours, good effect

Active Publication Date: 2011-01-12

云南大为化工装备制造有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing problems of the existing single-column mobile bandaging machine are: 1. The base is driven by ordinary electricity, the walking speed cannot be adjusted, the start, stop and operation are not stable, and the bandaging machine shakes greatly

In addition, the electric drive mechanism of the base is installed in the base, which is inconvenient for inspection and maintenance; 2. There is no lifting device on the truss, and the lifting and transportation of the wrapped workpiece need the assistance of other lifting equipment, and the work efficiency is low; 3. The clamping on the clamping device There is only one pair of claw teeth. When the clamping force is large, the edge of the claw tooth hole on the wrapping laminate is often stretched and deformed due to excessive tension, and the clamping effect cannot be achieved; 4. The whole wrapping machine is not equipped with a welding system. After wrapping the laminates, it is necessary to manually weld the longitudinal seam and the circular seam with a welding machine, and the work efficiency is very low; Tensioning, clamping of wrapping laminates, etc., due to the large number of control contents, there are many switches on the electric control box, which is prone to misoperation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

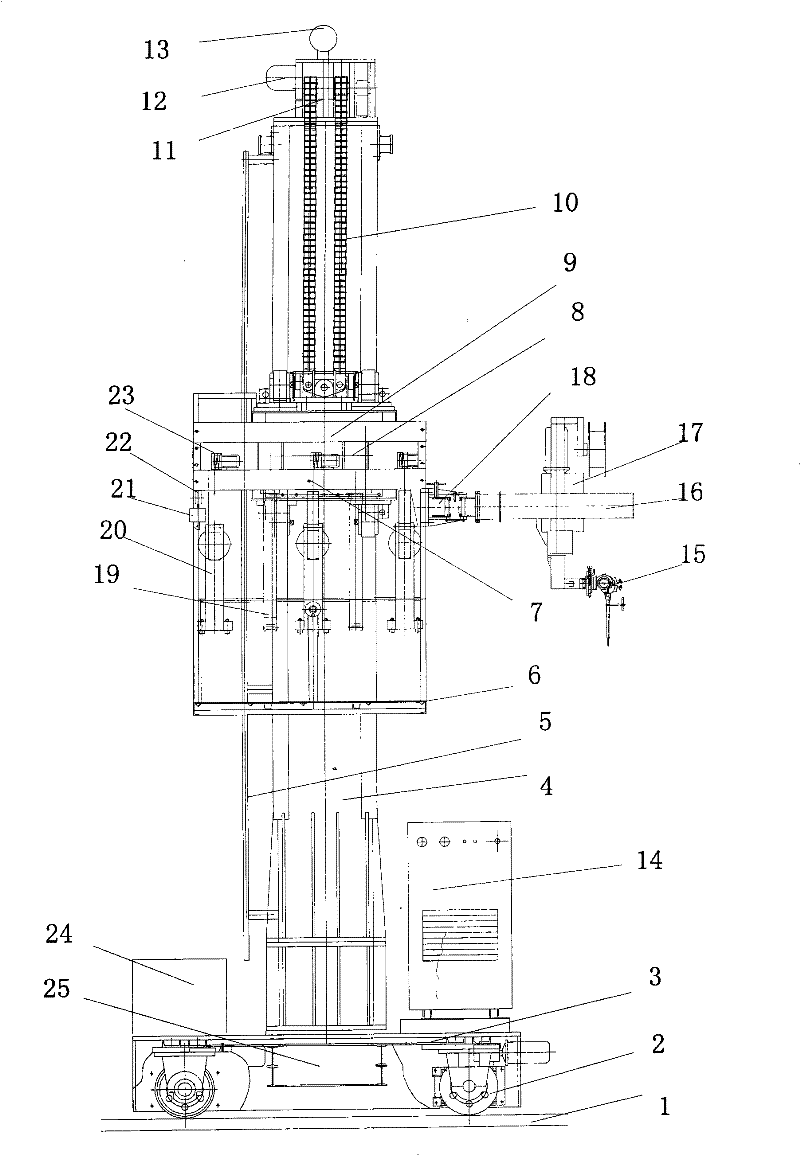

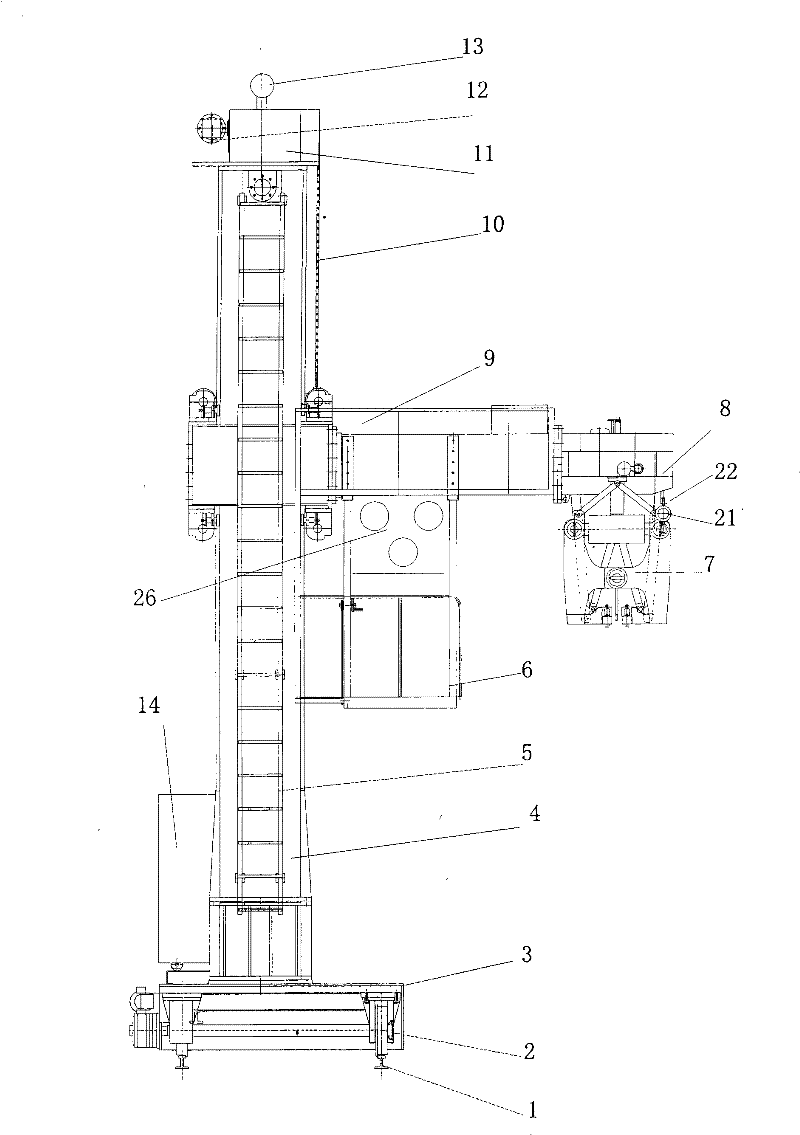

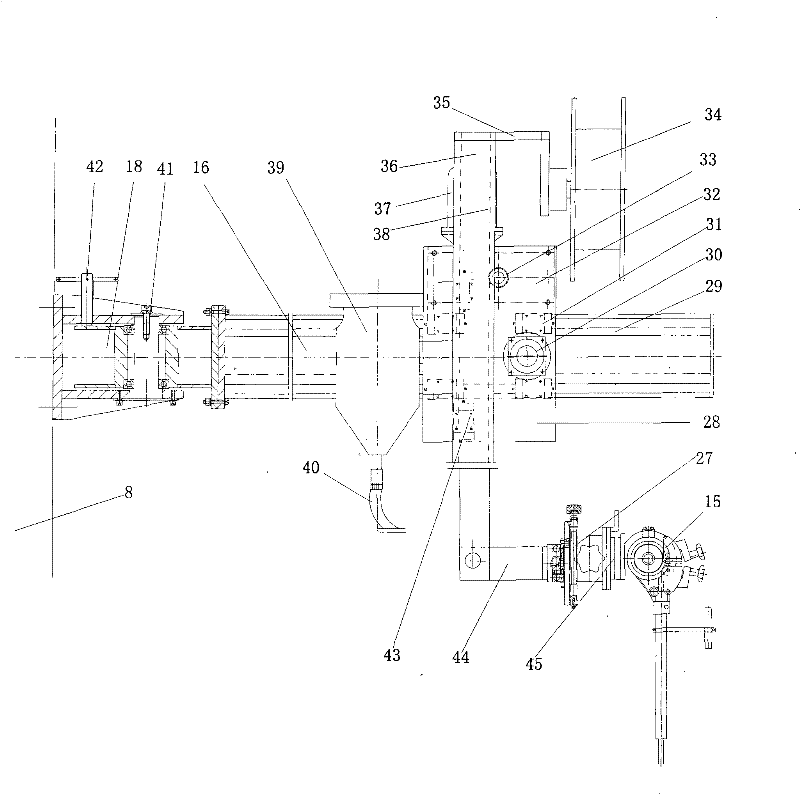

A multifunctional bundling machine which is used for multi-layer bundled metal pressure container is mainly used for bundling and welding of multi-layer bundled metal pressure container in manufacturing pressure container. According to the invention, the running of base (3) adopts a frequency-conversion speed-adjustment control. An electric driving device is positioned at the outside of base (3).A clamping mechanism (20) adopts double clamping teeth and the clamping is reliable. A longeron (8) is additionally installed with a welding machine transverse arm (16) which can rotate for 180 DEG on the horizontal plane. A welding device (17) can complete the automatic welding of longitudinal and transverse welding line of bundling laminated board. A hoisting device (22) is respectively installed at four corners of base of longeron (8). The hoisting and conveying of workpiece before bundling and after bundling can be executed. An electronic control box is three independent electric control boxes which respectively control the running of base (flat car) (3), lifting of transverse beam and welding of system. The multifunctional bundling machine of the invention can realize a plurality of functions of bundling, welding, hoisting, conveying, etc. of multi-layer bundled metal pressure container and has the advantages of high efficiency, excellent quality, smooth running and convenient operation maintenance.

Description

technical field [0001] The invention relates to a wrapping machine for multilayer wrapping metal pressure vessels, which is mainly used for wrapping and welding multilayer steel plates of multilayer wrapping metal pressure vessels in the manufacture of pressure vessels, and belongs to the field of metal pressure vessel manufacturing. Background technique Large pressure vessels, especially reaction vessels that are required to work under high temperature, high pressure and strong corrosive media, due to high pressure and strong corrosion of the medium, in order to ensure the safety of the container, the wall thickness of the container is designed to be very thick. It is a corrosion-resistant high-alloy material, which is not only difficult to process and produce, some even cannot be manufactured, and the price is very high. This type of container generally adopts a multi-layer wrapping method, that is, an inner cylinder is first made of ordinary carbon alloy steel, and a co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23P23/04

Inventor 谢梅生李亚民王坚李忠元赵泽斌

Owner 云南大为化工装备制造有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com