Three-roller tube-rolling machine

A technology of three-roll rolling and pipe mills, which is applied in the direction of metal rolling stands, metal rolling mill stands, rolls, etc., can solve the problems of reducing the performance of the reducer, poor frame rigidity, and long time, so as to improve the product quality. quality, improved bite conditions, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

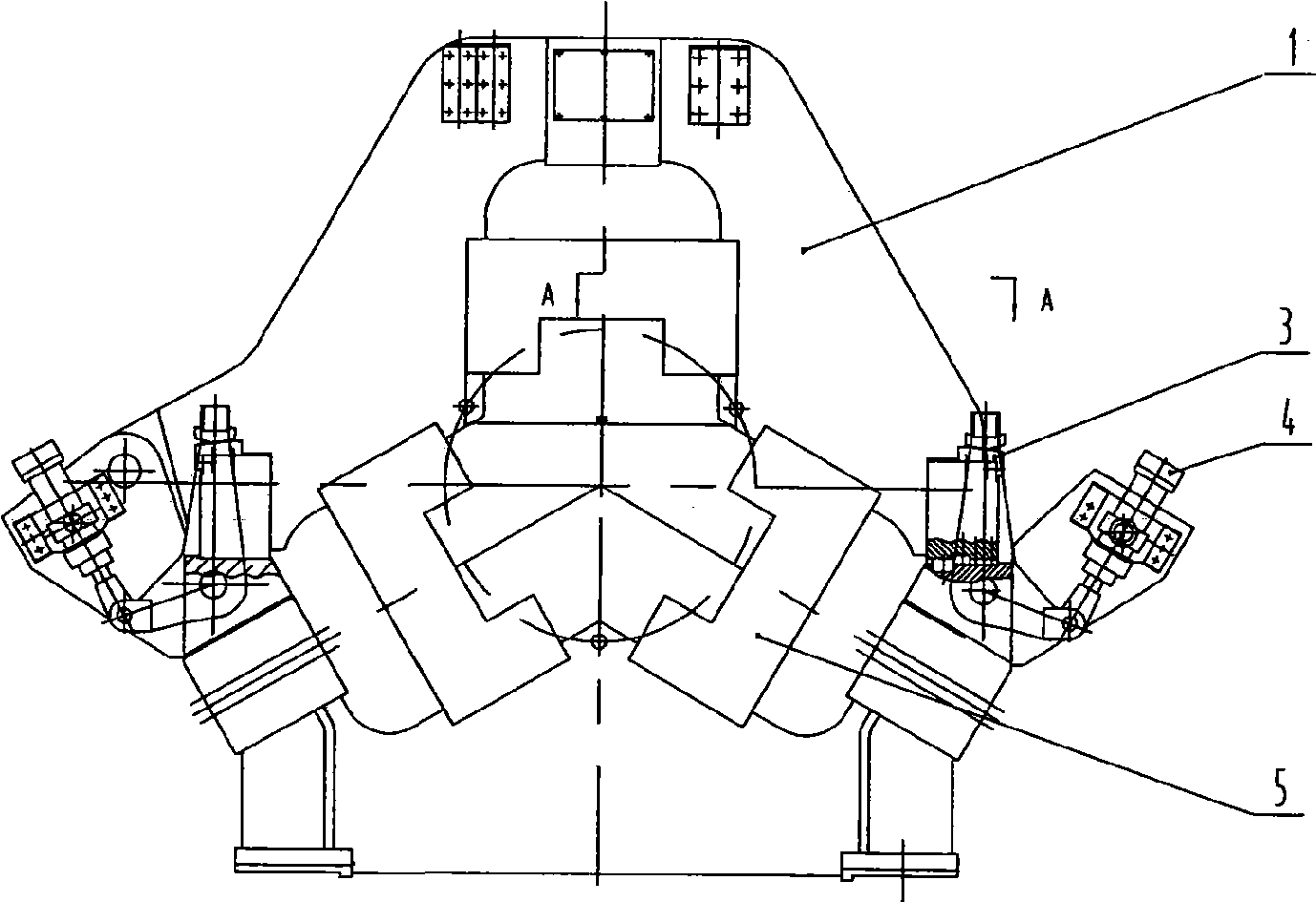

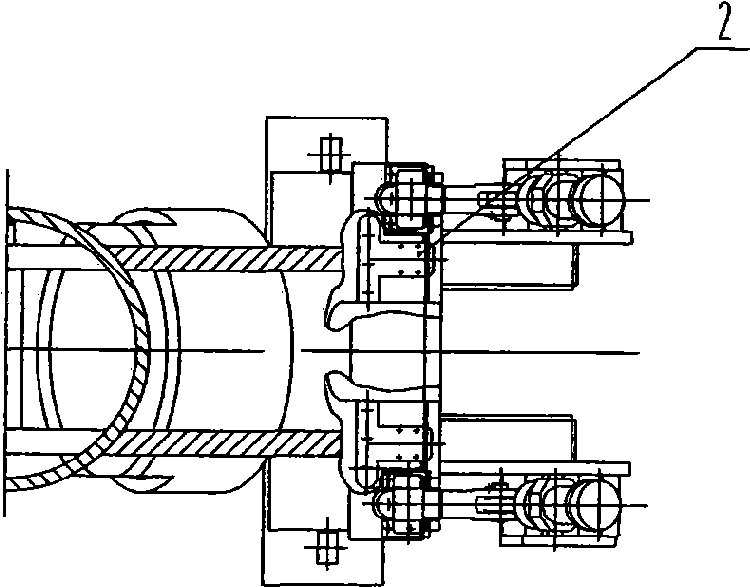

[0026] Such as figure 1 , 2 , 3, 4, 5, and 6, a three-roll pipe mill includes: a frame 1, three drums 6 placed in the frame, and three rolls 10 respectively installed on the drums, The main motor 11 is connected with the main transmission shaft 13 and the roller 10 through the main speed reducer 12 .

[0027] The frame 1 is a welded structure with upper and lower splits, and the connection and positioning of the upper and lower frames are guaranteed by four groups of T-keys 2; The above-mentioned four pull rod wedge mechanisms can keep self-locking after being locked, and their opening and closing are driven by four hydraulic cylinders 4 .

[0028] The frame 1 has three cylinders 5 with an angle of 120° to each other, and precise bore holes are arranged in the cylinders 5 for installing the rotating drum 6 . This structure can increase the rigidity of the frame and ensure the matching accuracy of the drum 6, so as to improve the stability of the three-roll pipe mill during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com