Structure for drawing out lead wires from a coil device

A technology of coil device and lead-out structure, which is applied to the parts, coils, valve devices and other directions of the connection device, can solve the problems of fracture and hidden dangers in strength, and achieve the effect of preventing the wire portion from breaking and maintaining the connection state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention will be described below with reference to the drawings. In addition, in the following description, the present invention is applied to Figure 9 The electric valve shown is driven by the coil device 65 of the stepper motor used.

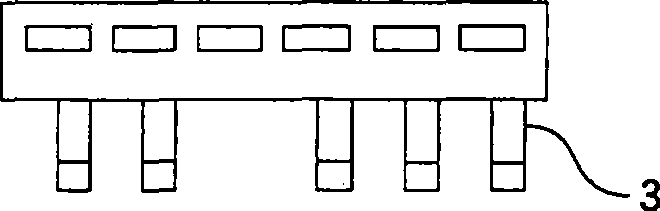

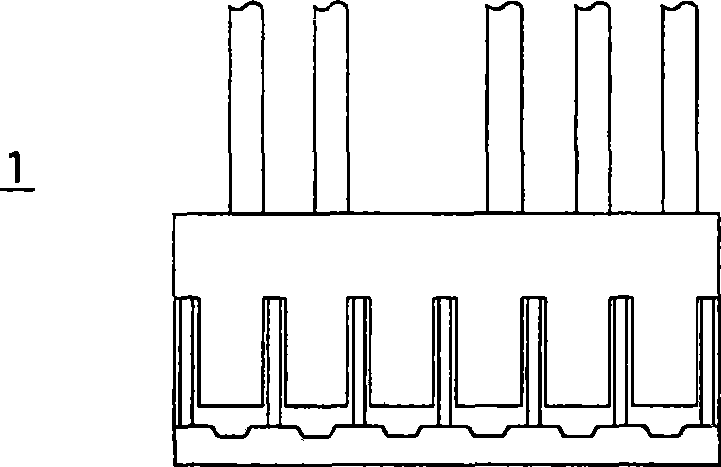

[0055] Figure 1(a)-Figure 1(e) It shows a connector constituting the lead-out structure of the coil device of the present invention. The connector 1 consists of a lead wire 2, a crimp terminal 3 mounted on the top end of the lead wire 2, and a housing that engages with the crimp terminal 3 and holds the lead wire 2. 4 constitute.

[0056] The crimp terminal 3 is formed of a thin metal plate such as Figure 2(a)-Figure 2(c)Shown includes: a wire holding portion 3a holding the wire portion 2a of the lead wire 2 (refer to FIG. 1 ); a covering holding portion 3b holding the covering portion 2b of the lead wire 2; protruding perpendicularly to the axial direction of the wire portion 2a of the lead wire 2 Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com