Improved terminal, particularly for automatic circuit breakers

An automatic circuit breaking and terminal technology, which is used in the manufacture of protective switch terminals/connections, circuits, and contacts, and can solve the problems of low crimping torque and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

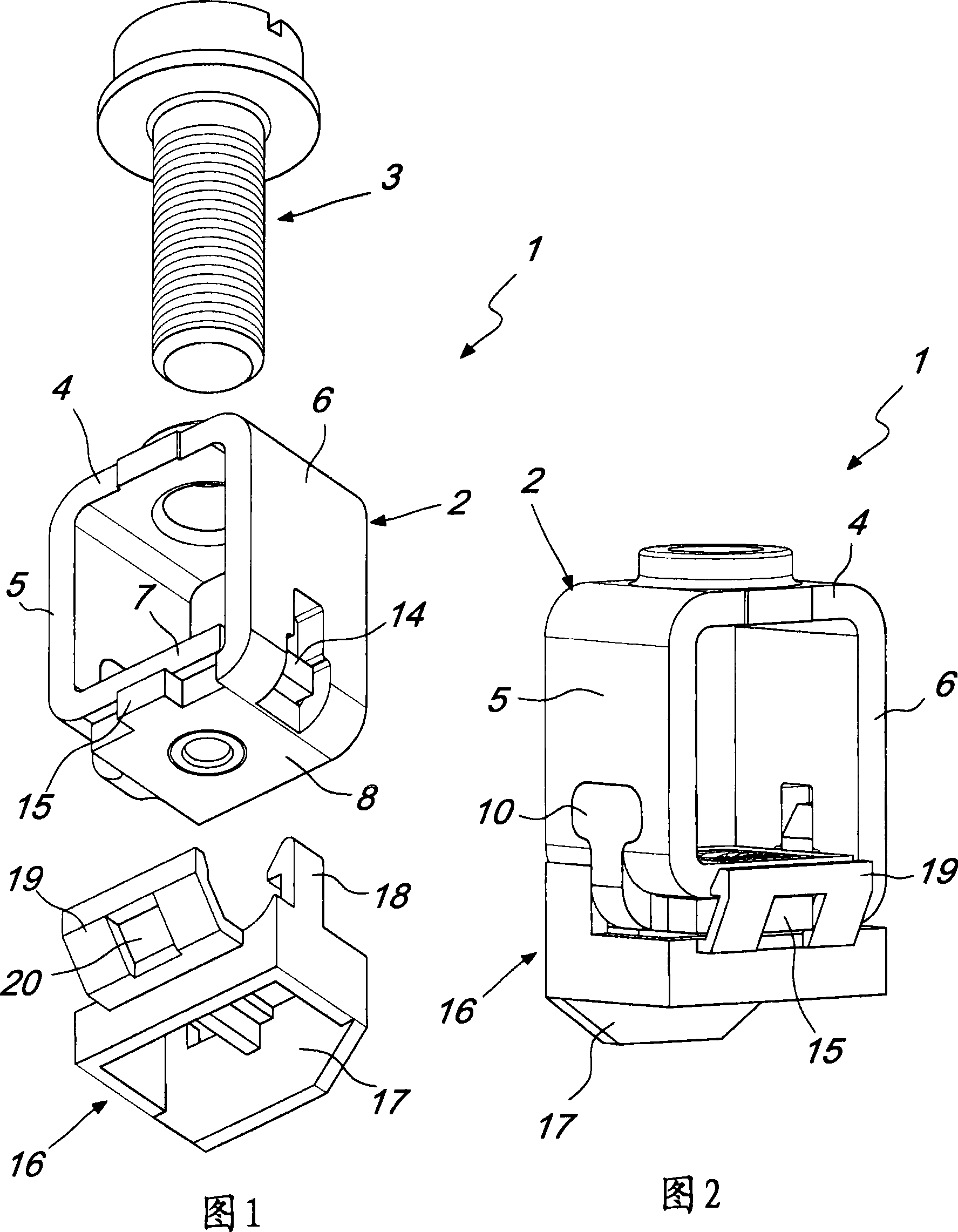

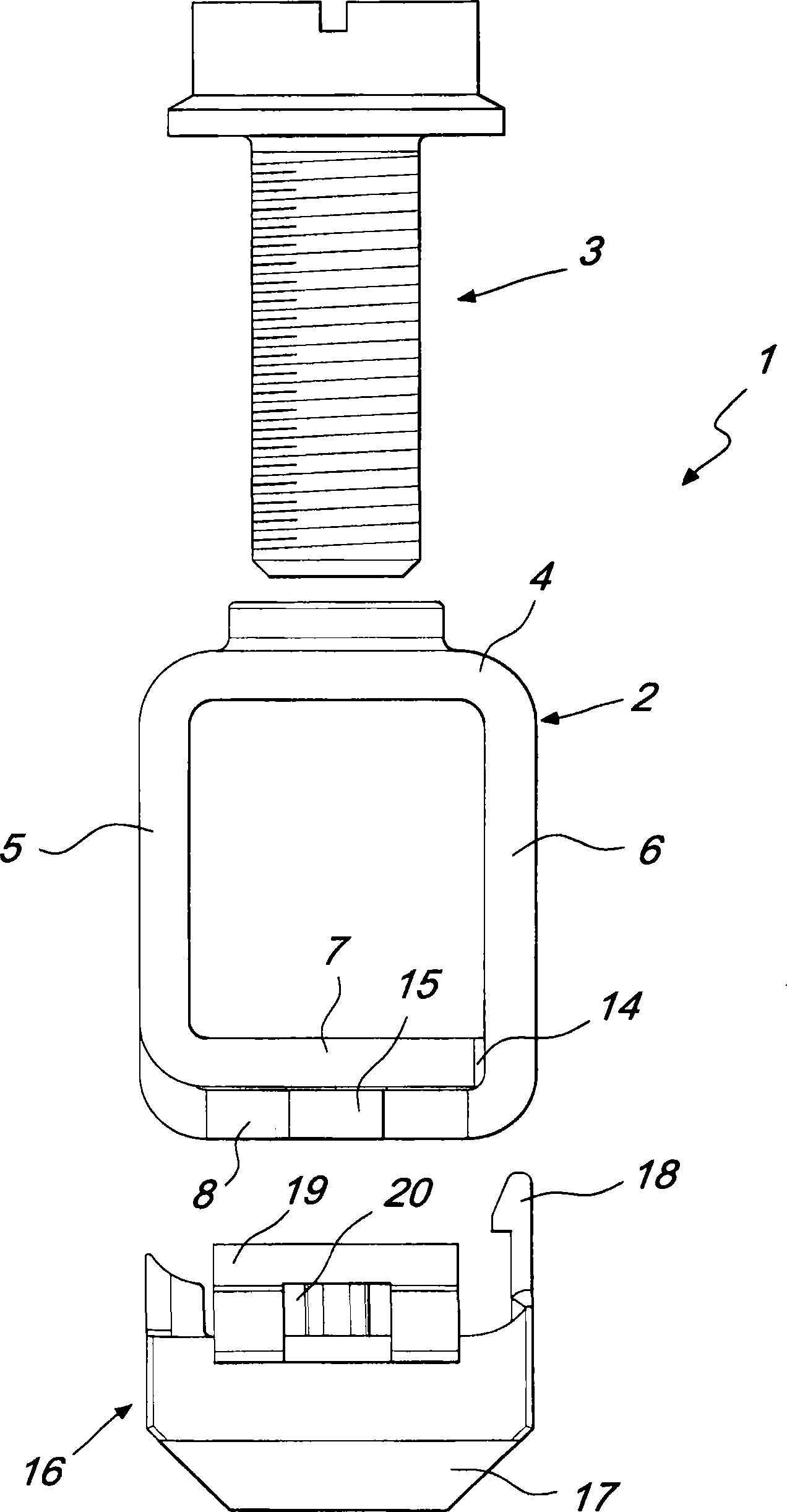

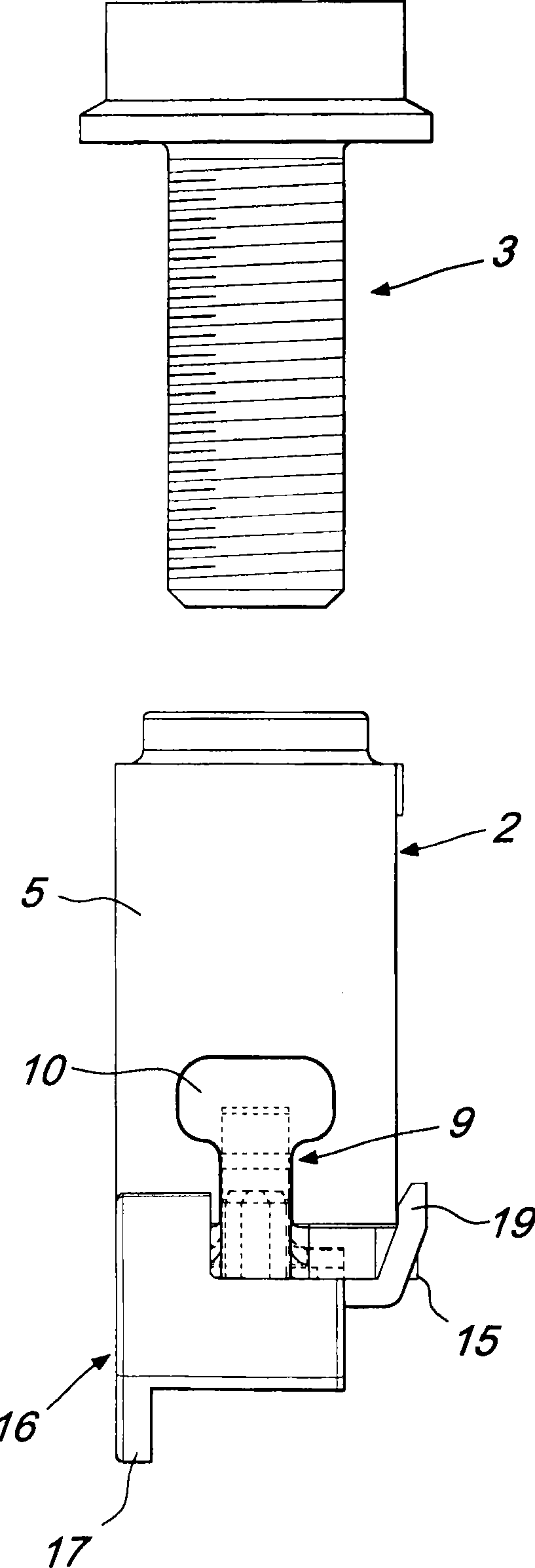

[0031] Referring to the above-mentioned figures, the terminal according to the invention is generally designated by the numeral 1 and comprises a parallelepiped-shaped body 2 and a clamping screw 3 . The pressing screw 3 is connected with the body 2, so that the end of the conductive cable (not shown in the figure) can be pressed against by acting on the screw, so that the end of the cable is located in the body 2 inside the parallelepiped 2 between the bottom of the connector and the end of the terminal strip (not visible in the figure).

[0032] The parallelepiped 2 is formed from a single metal sheet which has been punched and bent.

[0033] The body 2 is composed of an upper surface 4 and two side walls integrated with the upper surface, the two side walls are respectively a first side wall 5 and a second side wall 6 .

[0034] The end of the first side wall 5 has an inner underside 7 and the end of the second side wall 6 has an outer underside 8 .

[0035] The two under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com