Infrared light transmission sandwich structure composite material based on silver dendritic structure

A composite material and dendritic technology, which is applied in the field of infrared light-transmitting composite materials and their preparation, can solve the problems that the preparation structure cannot overcome the limit of lithography, damage the structure and morphology, and the preparation cost is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

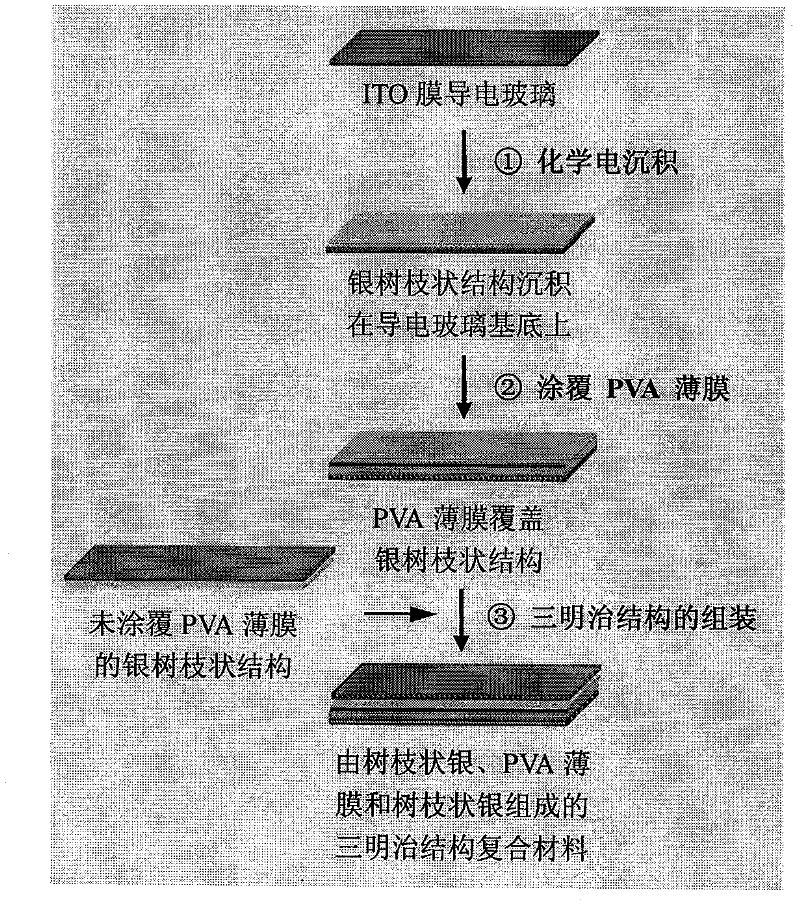

[0020] 1. Preparation of silver dendritic structure: adopt chemical electrodeposition method, with indium tin oxide (ITO) transparent conductive glass as cathode, with smooth surface, the silver sheet that purity is 99.9% is anode, the distance between two flat electrodes is 0.6mm. AgNO at a concentration of 0.589mM 3 The ultrapure aqueous solution is the electrolyte, and it is energized at a DC voltage of 0.4-0.8V for 1 minute, and a cell diameter of 0.5-6.5 μm and a distribution density of 5.76×10 can be obtained on the conductive glass substrate. 4 -4.58×10 5 piece / mm 2 nanobranched silver dendrites.

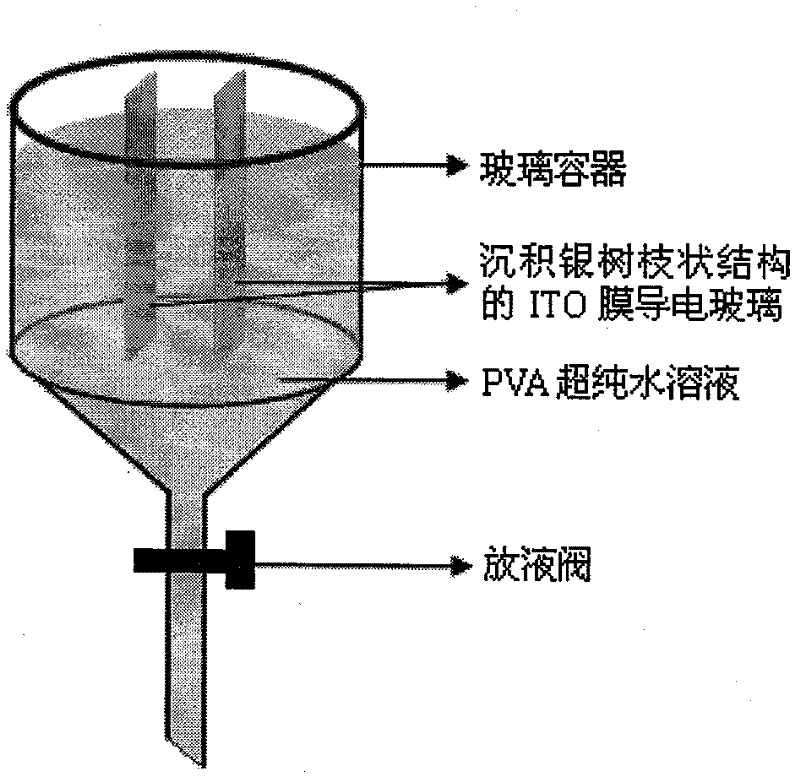

[0021] 2. Preparation of PVA film: Utilizing the principle of vertically pulling the coating film, using a self-designed liquid level drop coating device, using 3% (w / v) PVA ultra-pure aqueous solution as the coating liquid, at room temperature 25 ° C, Hang the sample deposited with silver dendritic structure in the coating solution, and adjust the falling speed of the co...

Embodiment 1

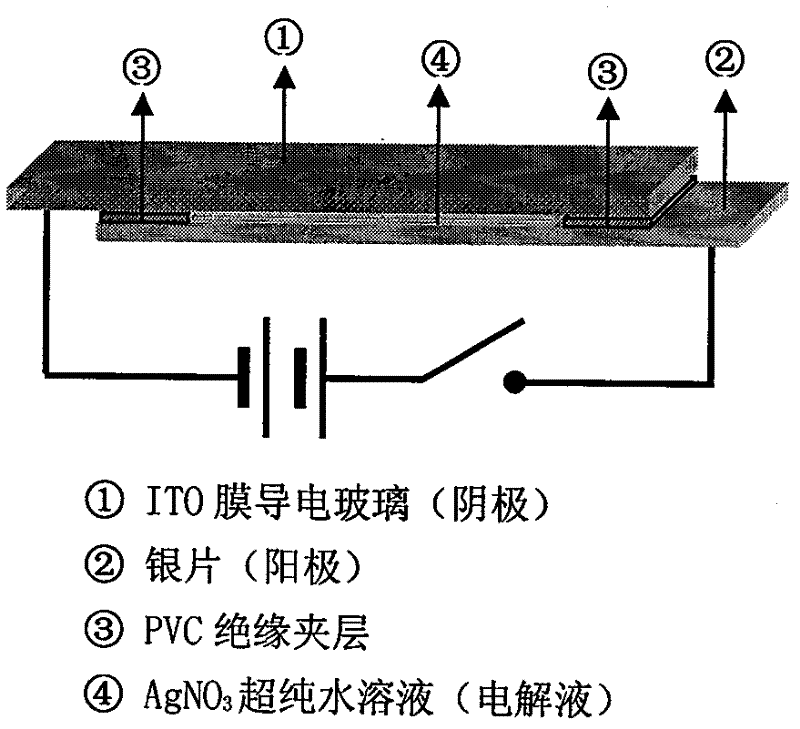

[0025] Embodiment 1: In the process of preparing the silver dendritic structure, a flat conductive glass with a square resistance of 17Ω was cut and cleaned according to the specification of 8 mm×4 mm by chemical electrodeposition method, and used as a cathode. A silver sheet (purity of 99.9%) with the same size specification as the cathode and a flat surface is used as the anode. Two plate electrodes are attached figure 2 The device shown is separated by two sheets of polyvinyl chloride with a thickness of 0.6 mm, so that the distance between the two electrodes is maintained at 0.6 mm. Accurately weigh 500mgAgNO 3 (Analytical pure) Add to a 50ml volumetric flask, then add ultrapure water with a resistivity of 18.24MΩ-cm to the scale, this solution is used as the electrolyte mother solution; use a 1ml pipette to accurately measure 1ml and add 100ml of capacity bottle, and then diluted to the mark with the same ultrapure water, this solution is the electrolyte solution, and ...

Embodiment 2

[0027] Embodiment 2: In the process of preparing the PVA film, a self-designed liquid level drop coating device is used to coat the PVA film on the surface of the silver dendritic structure prepared according to the conditions of Example 1. Accurately weigh 7.5g of polyvinyl alcohol (analytically pure) into a 250ml beaker, add 250ml of ultrapure water, stir and heat until boiling, stop heating after the polyvinyl alcohol is completely dissolved, and transfer the solution to a 250ml volumetric flask after cooling to room temperature , add ultrapure water to the scale (part of the water is evaporated when heated and dissolved), and then the coating solution (3% PVA ultrapure aqueous solution) used for the coating film is obtained. Add the coating liquid as image 3 In the glass container (capacity is 250m1) on the upper part of the film coating device shown, and then press the sample image 3 Hang in the coating liquid as shown, adjust the liquid discharge valve, control the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com