Injection cylinder in injection apparatus for molding metal material

一种金属材料、注射装置的技术,应用在压注缸领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

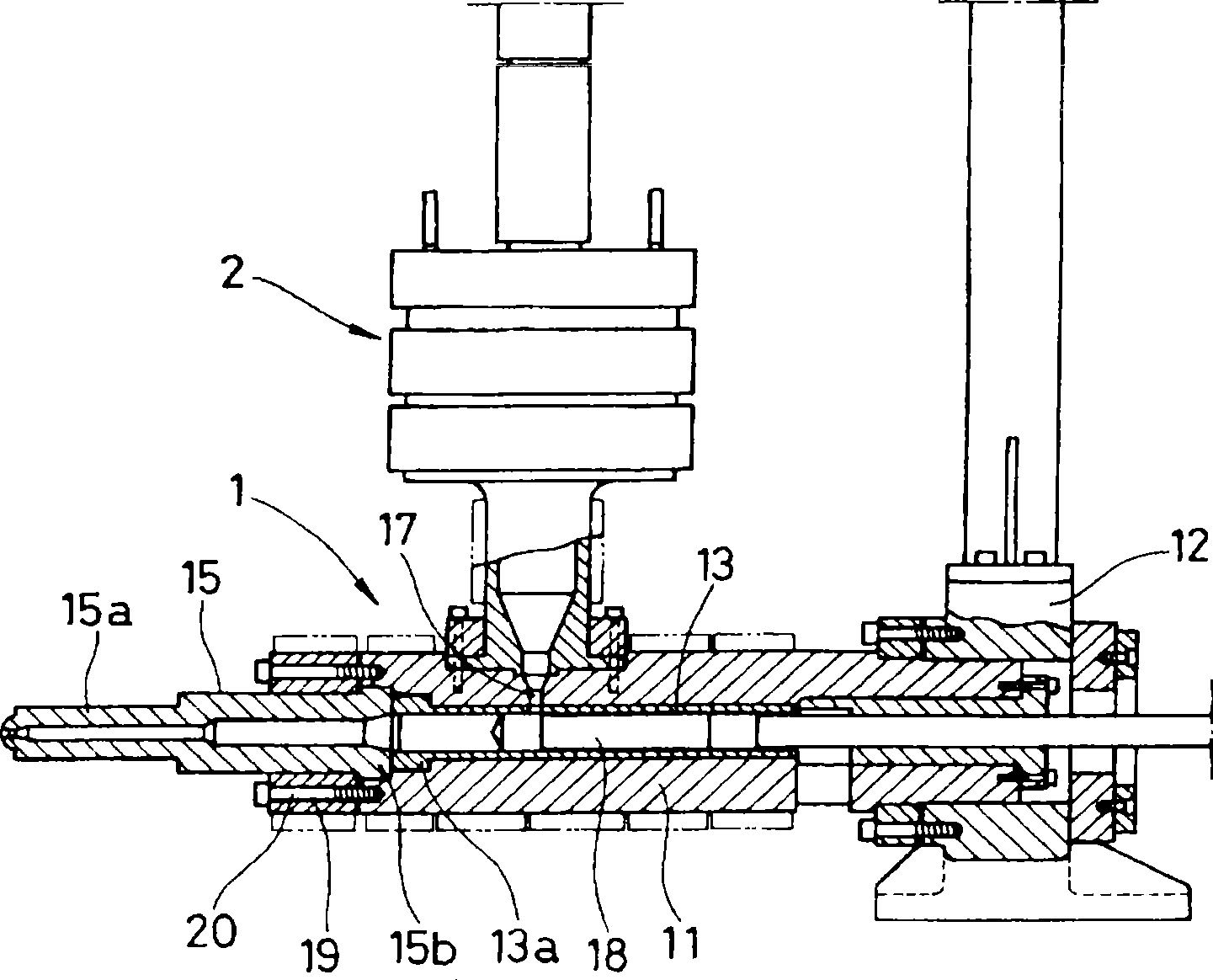

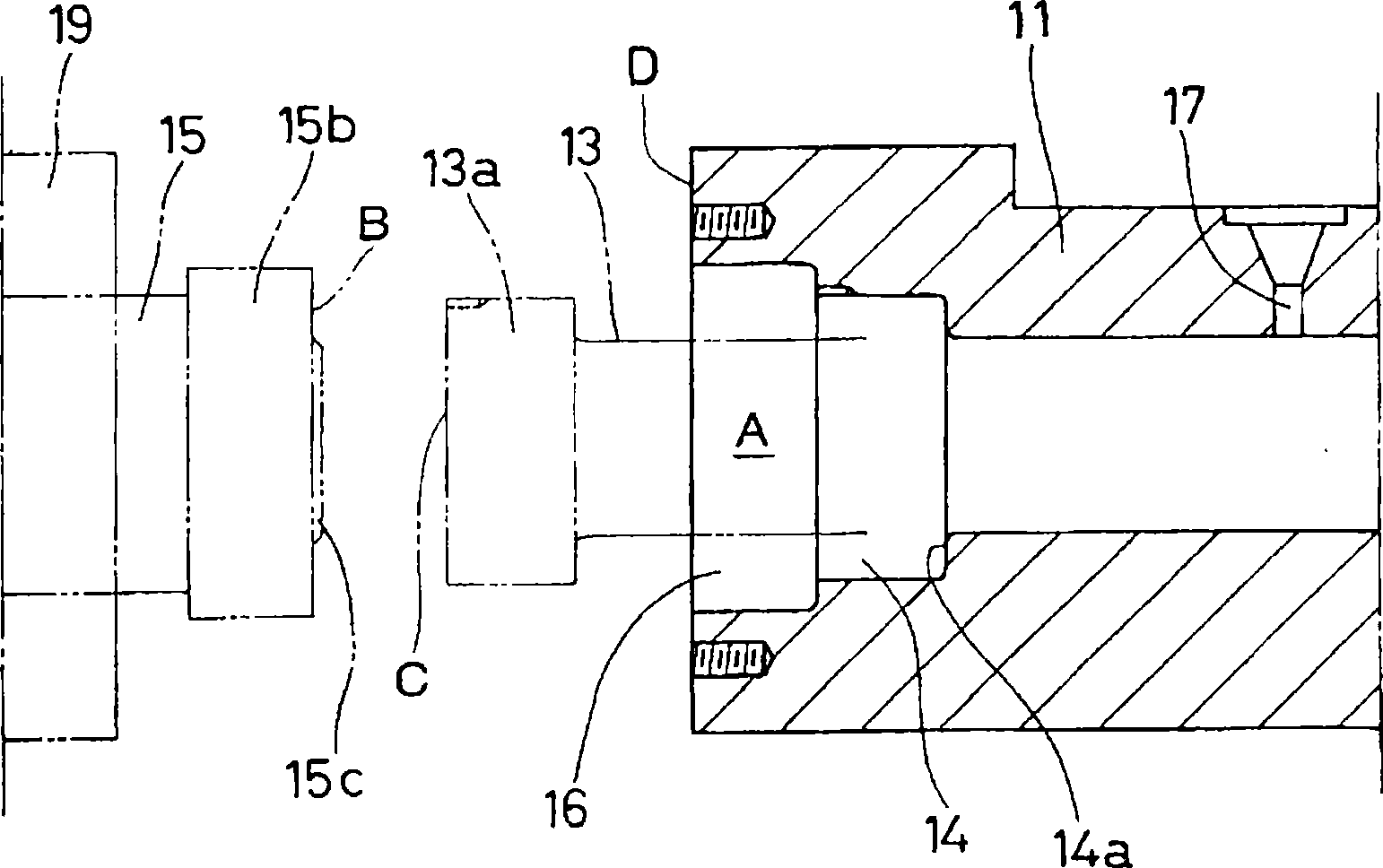

[0028] exist Figure 1-4 Among them, reference numeral 1 indicates an injection cylinder, which is placed horizontally on a base not shown, and the rear end of the cylinder body 11 passes through and is fixed on the holding plate 12 . The cylinder 11 has heating means on its circumference. Reference numeral 2 designates a material melting and storage unit, which is arranged at the front of the cylinder 11 .

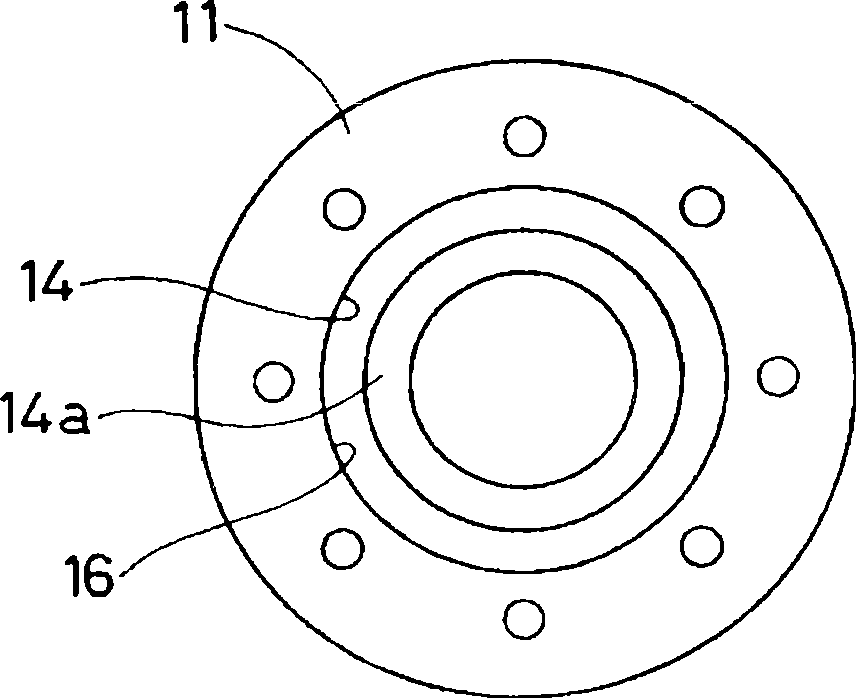

[0029] The cylinder block 11 is composed of a cylinder having a first mounting portion 14 and a second mounting portion 16 at its front end opening A. As shown in FIG. The flange 13 a of the cylinder liner 13 is mounted to the first mounting portion 14 , and the flange 15 a of the nozzle member 15 is mounted to the second mounting portion 16 . A delivery opening 17 is formed on the front top side of the cylinder 11 . As mentioned, the cylinder liner 13 passes through the cylinder. The inner wall of the cylinder liner 13 forms a cylinder hole into which a plunger 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com