Tool and method for burning/recording liquid crystal display panel

A technology of liquid crystal display panel and burning method, which is applied in the direction of instruments, electrical digital data processing, etc., and can solve problems such as redundant operation steps, missed burning, and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

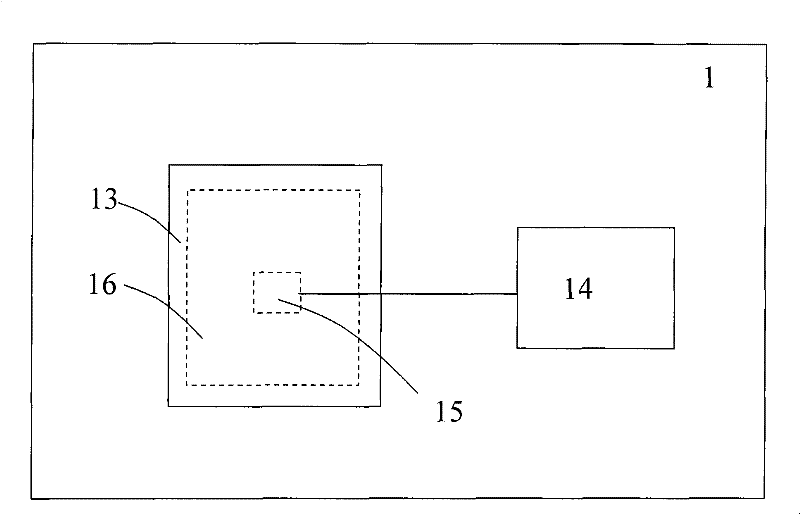

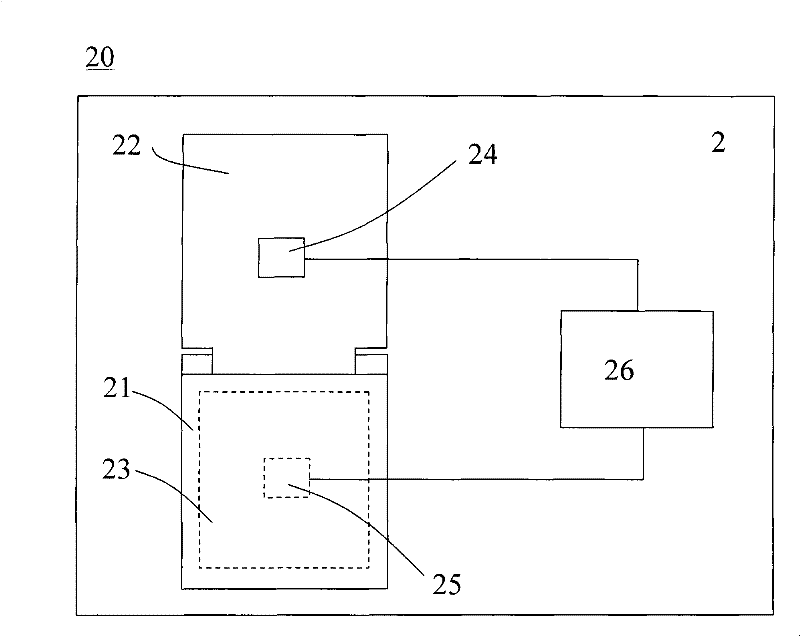

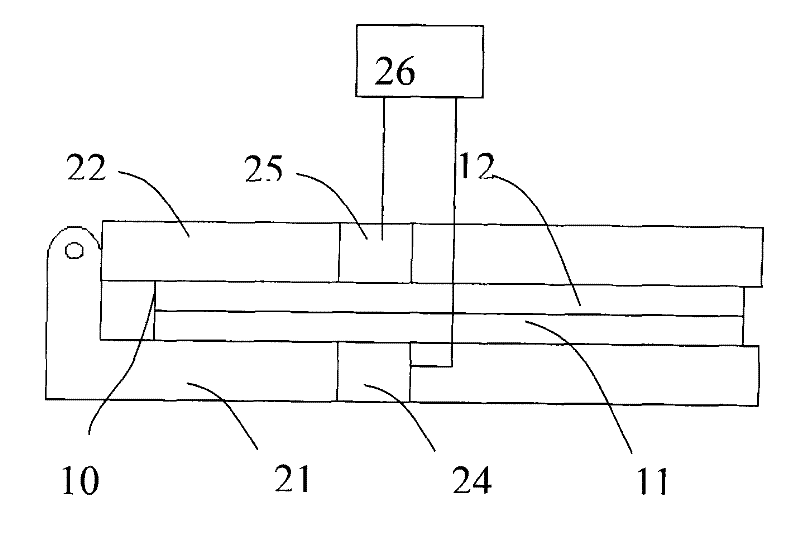

[0014] see figure 2 and image 3 , figure 2 It is a schematic diagram of a liquid crystal display panel burning jig according to the present invention, image 3 It is a schematic diagram of the combination of the burning fixture and the liquid crystal display panel when burning the liquid crystal display panel according to the present invention. In this embodiment, the liquid crystal display panel 10 has a first display screen 11 and a second display screen 12, the first display screen 11 and the second display screen 12 are arranged oppositely, and the liquid crystal display panel burning fixture 20 includes a base 2 , a first part 21 , a second part 22 , a first sensor 24 , a second sensor 25 and an information processing device 26 . The first part 21 is disposed on the base 2 , the second part 22 is rotatable to cover the first part 21 , and the placement area 23 of the liquid crystal display panel 10 is disposed on the first part 21 . It can be understood that the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com