Neural network control method for direct-blowing type coal mill

A kind of neural network control and neural network technology, which is applied in the field of neural network control of direct blowing coal mills, can solve the problems of automatic control systems such as inability to control optimally, large time lag, and large inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

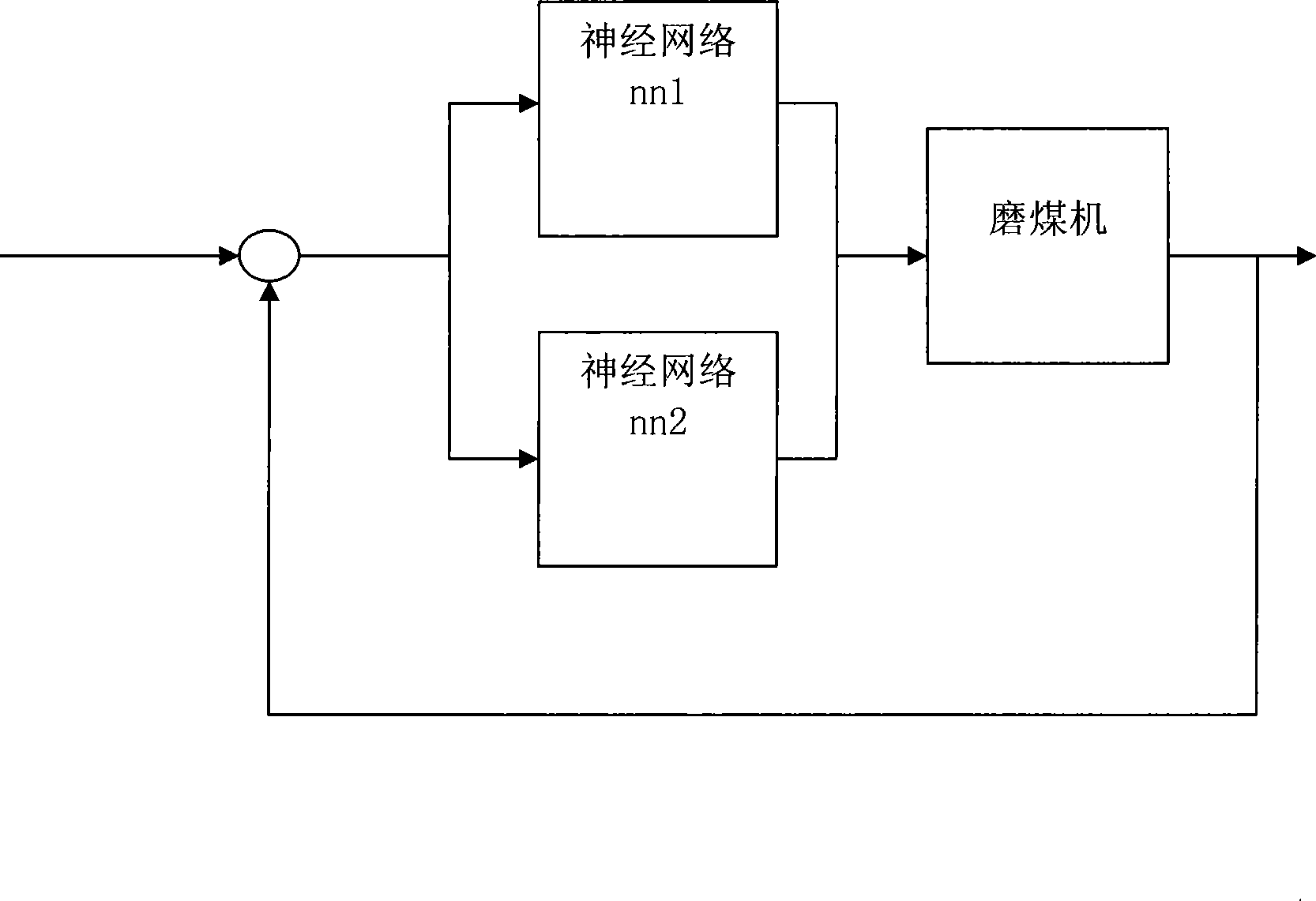

[0006] 1. The present invention is implemented using an intelligent neural network control method.

[0007] 2. The neural network control method referred to in the present invention is realized jointly by a single neural network and a neural network series network.

[0008] 3. The realization form of the single neural network referred to in the present invention is:

[0009] (1) Read the working characteristic parameters of the steel ball mill;

[0010] (2) According to the test results of the comprehensive parameters of the steel ball mill load in the previous stage, the weight and threshold of the neural network are given appropriate initial values;

[0011] (3) Ant particle swarm algorithm is used to learn the weight of the linear part in the neural network;

[0012] (4) The weight of fixed linear part, adopts BP algorithm to train the weight and threshold of dynamic recursive neural network in network;

[0013] (5) If the error function meets the requirements, stop the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com