Circulating fluidized bed boiler ignition apparatus and method thereof

A circulating fluidized bed and boiler technology, which is applied to combustion methods, combustion ignition, lighting and heating equipment, etc., can solve the problems of frequent furnace shutdowns for maintenance and wear, and achieve the effects of reducing start-up costs, saving fuel, and being easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

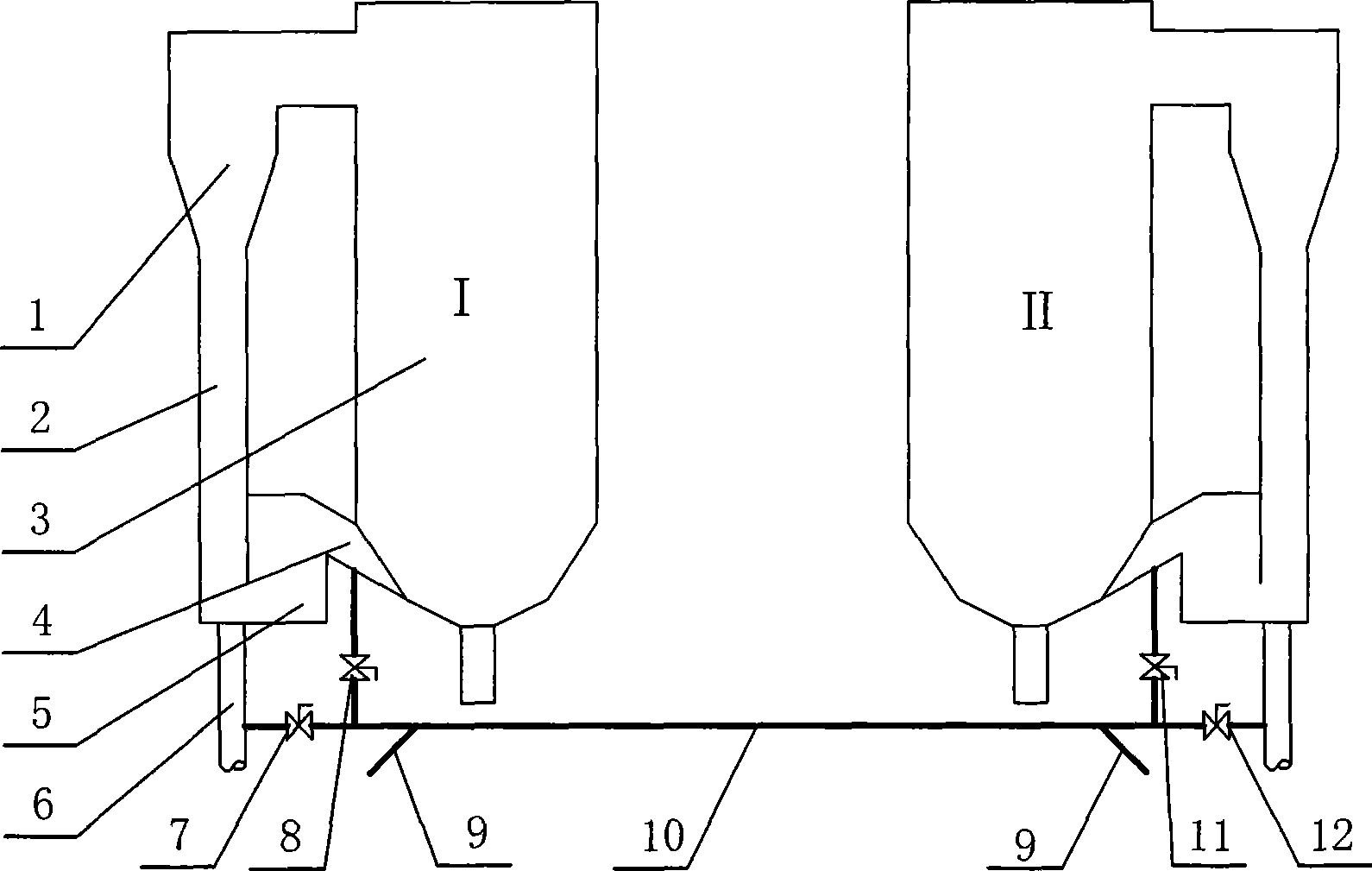

[0011] Such as figure 1 As shown, the left side is No. I circulating fluidized bed boiler, and the right side is No. II circulating fluidized bed boiler. Each circulating fluidized bed boiler includes a cyclone separator 1, a standpipe 2 and a feeder 5 installed under the cyclone separator. A red slag conveying device is connected to the slag discharge pipe 6 at the lower end of the feeder 5 of the two boilers. The device is a pneumatic conveying device, and valves are respectively installed between the pneumatic conveying device and the slag discharge pipe 6 . The outlet 4 connecting the feeder and the boiler is respectively connected with branch pipelines connected with the power conveying device, and valves are respectively installed on the branch pipelines.

[0012] When the No. I circulating fluidized bed boiler needs to be ignited and started after overhaul, the valve I7 and valve III11 are closed, and the valve II8 and valve IV12 are opened. At this time, the high temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com