Method for manufacturing metal hand tool

A manufacturing method and technology of hand tools, applied in the field of hand tools, can solve the problems of easy falling off, inconspicuous marking effect, short-term marking effect, etc., and achieve the effect of obvious marking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

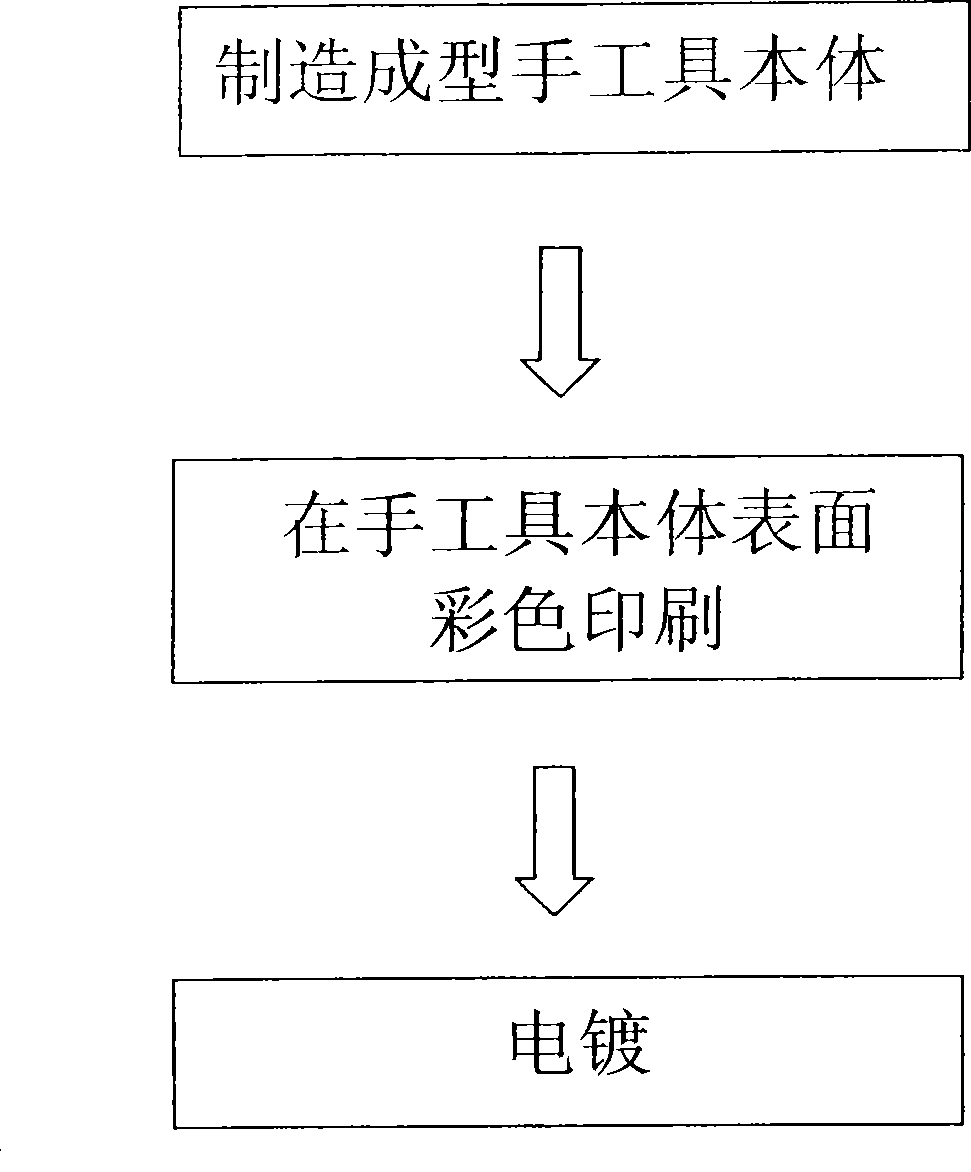

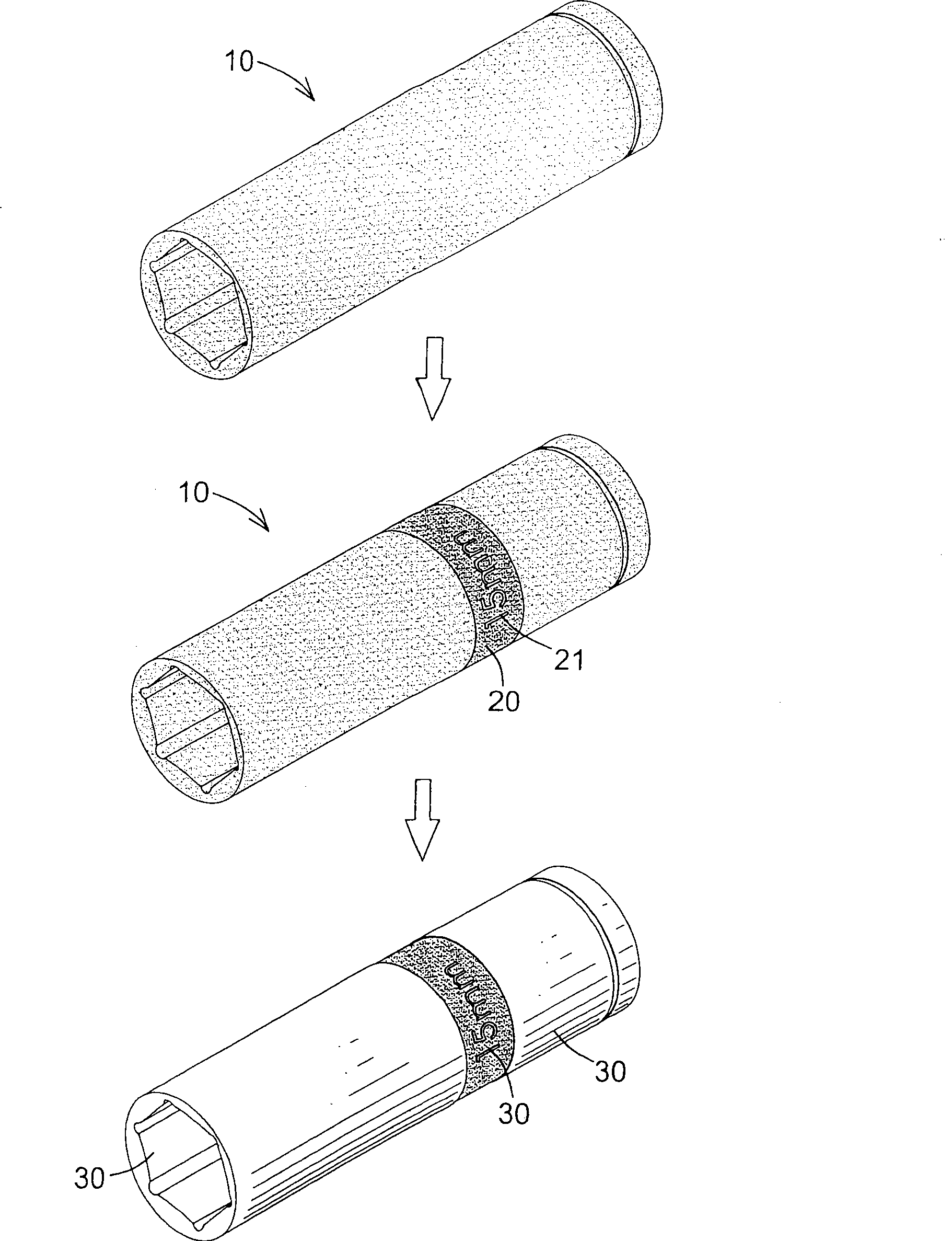

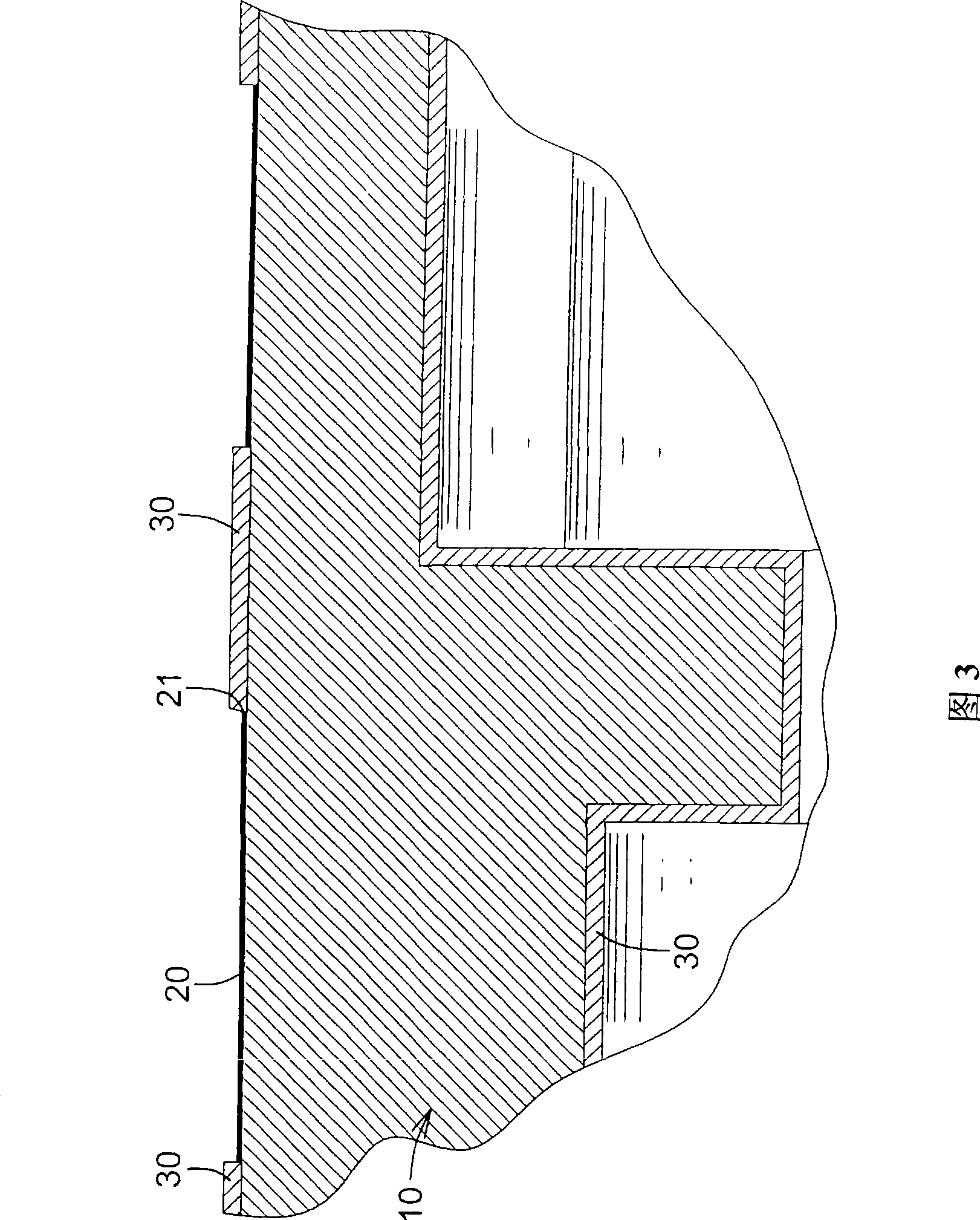

[0021] see figure 1 and figure 2 shown, where figure 2 The sleeve is taken as an example to illustrate its manufacturing method, but it is not limited to manufacturing the sleeve, it can also be applied to other metal hand tools such as wrenches or screwdrivers, so it is hereby explained first.

[0022] Manufacturing method of the present invention comprises:

[0023] 1. Manufacturing the shaped hand tool body: forming the hand tool body 10 by casting or forging;

[0024] 2. Color printing: color printing is performed on a predetermined area on the surface of the hand tool body 10 to form a printing layer 20, which can be printed in one color or multi-colored in printing. The hollowed-out graphic part 21 is formed within the range of the printing layer 20;

[0025] 3. Electroplating: electroplating on the surface of the hand tool body 10, because the pigment of the printing layer 20 is an insulator, so during electroplating, the electroplating layer 30 will not adhere to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com