Complex optical film series and method for producing the same

A composite film and optical film technology, applied in optics, nonlinear optics, layered products, etc., can solve the problems of anti-vibration, anti-humidity and heat of optical film components, increase optical film systems, etc., and improve the ability to resist complex environments power, high optical transmittance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

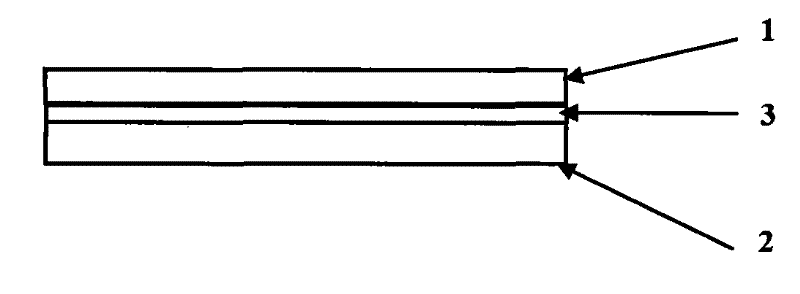

[0024] refer to figure 1 , use a film sticking machine to stick the DBEF film (1) on the double-sided anti-reflective glass (2) evenly, and no air bubbles and sundries should enter;

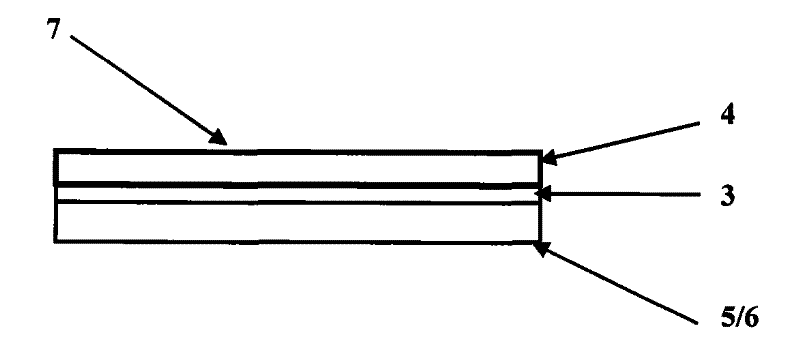

[0025] refer to figure 2 , use the same method to compound two pieces of BEF film (4) on two pieces of double-sided anti-reflective glass (5, 6), pay attention to the prism side of the BEF film facing upward, and ensure that the direction of the two pieces of mirror prism is vertical after compounding ;

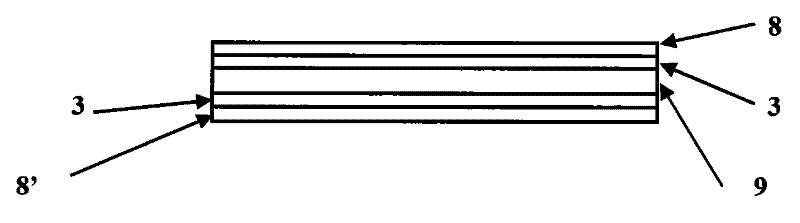

[0026] refer to image 3 , compounding two diffusion films (8, 8 ') on the infrared cut filter (9);

[0027] Finally follow Figure 4 Glue the above four pieces of composite film together in sequence and seal them with sealing glue.

[0028] If bubbles are encountered during the compounding process, the bubbles can be removed under high temperature and high pressure with a defoaming machine.

[0029] The manufacturing method of the composite film system is carried out according to the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com