Heat exchanger

A technology of heat exchange device and heat exchange flat tube, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., which can solve the problems of large heat exchanger volume and small heat exchanger volume, and achieve heat transfer The effect of large coefficient, small volume and enhanced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

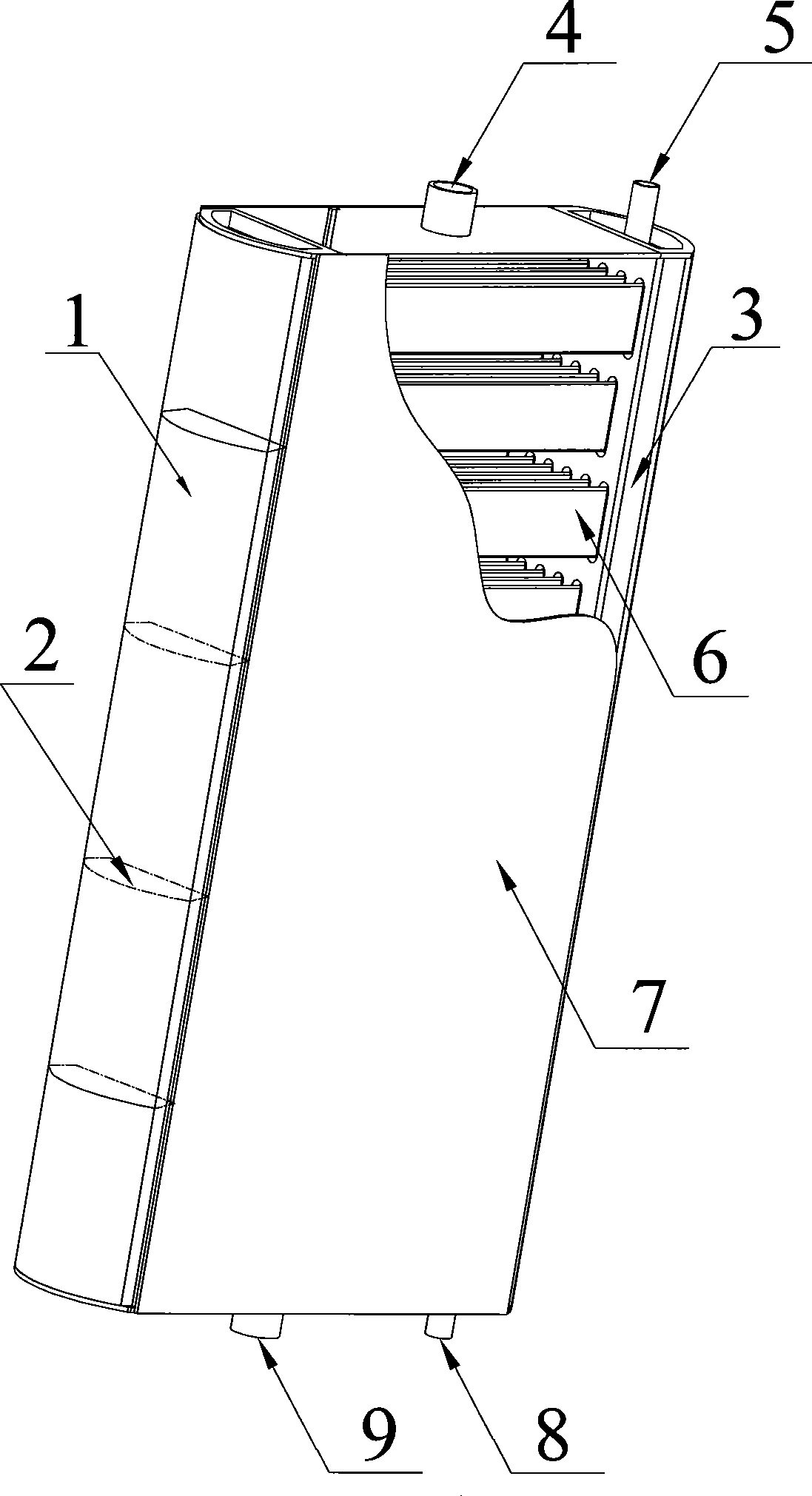

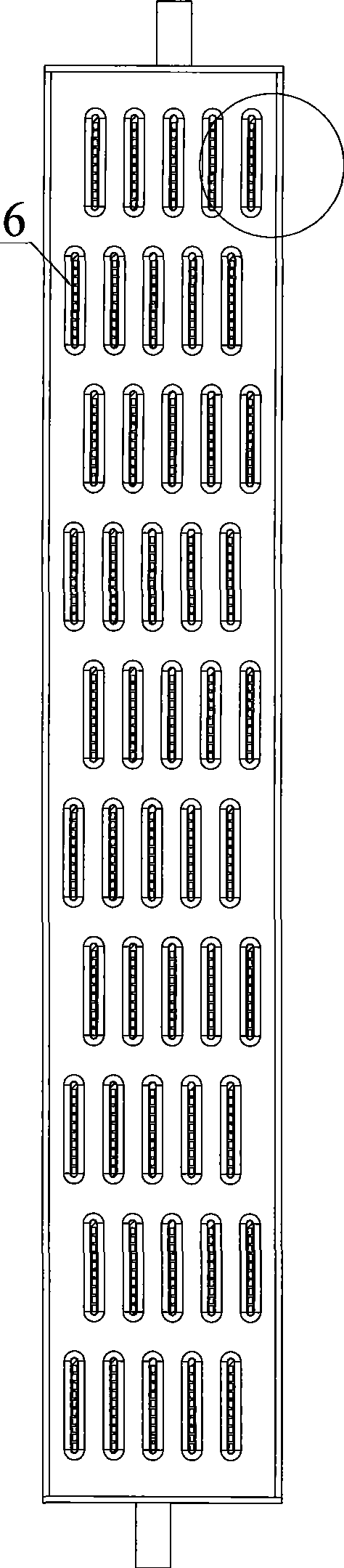

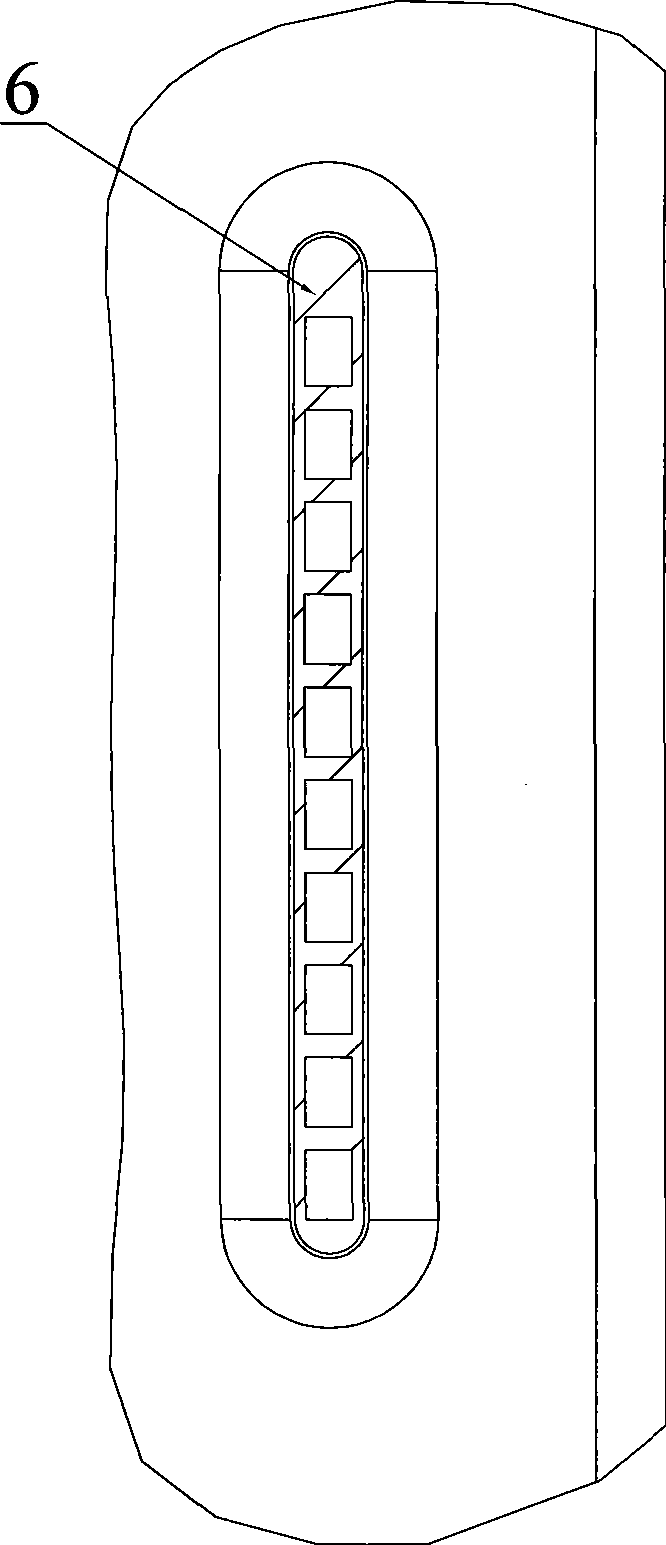

[0019] A heat exchange device such as figure 1 As shown, it includes left header 1, right header 3, heat exchange flat tube 6 and shell 7, forming a closed rectangular parallelepiped, and multiple rows of heat exchange flat tubes 6 are arranged in a rectangular shell 7 in a staggered arrangement up and down. The heating flat tube 6 is fixed to the front and rear sealing plates of the housing 7 and has reinforcing ribs. The plane of the heat exchange flat tube is parallel to the axial direction of the header. The left and right ports of the heat exchange flat tube 6 are respectively welded to the left collector. The flow pipe 1 and the right header 3 are provided with a baffle plate 2 inside the left header 1 and the right header 3, so that the left header 1, the right header 3 and the heat exchange flat tube 6 form a seal. There are also "S"-shaped circulation passages connected end to end, and there are multiple circulation passages inside the heat exchange flat tube 6; in ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com