Frame spinning semi-tight spinning process

A ring spinning machine, semi-compact technology, applied in the spinning machine, continuous winding spinning machine, textile and paper making, etc., can solve the defect of three-dimensional twisting triangle area, increase spinning breakage rate, yarn Improve the anti-pilling level of the fabric, reduce hairiness and spinning breakage rate, and improve the evenness of yarn dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention adopts the imported spinning frame Zinser 319, the spinning count is Nm36, and the trial spinning raw material is semi-combed wool.

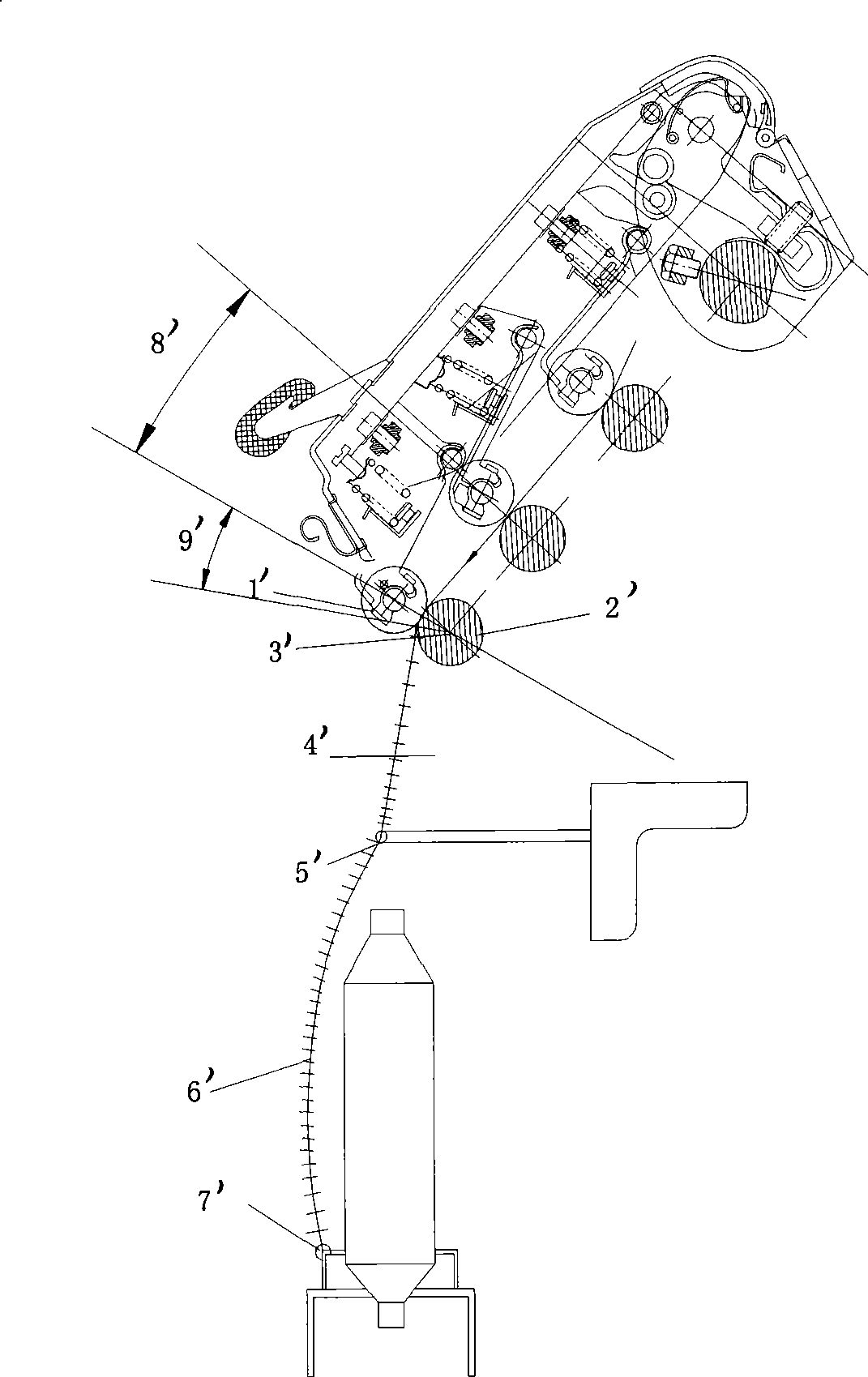

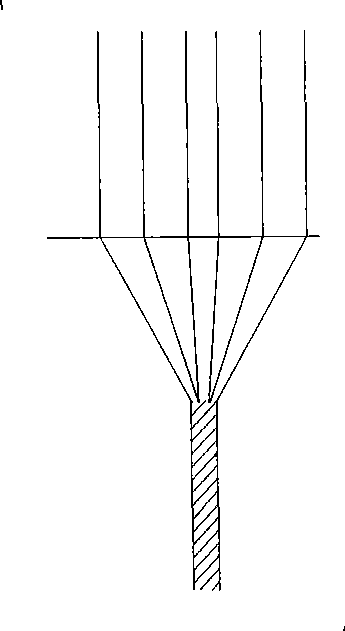

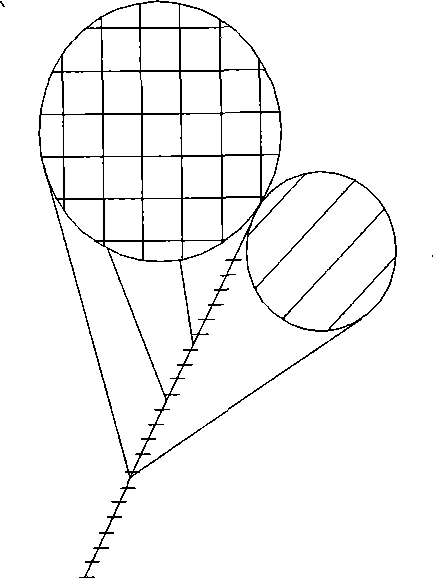

[0037] see Figure 4 It is the structural representation of the semi-compact spinning device of the present invention and Figure 5 for Figure 4 As shown in the A-A sectional view of the ring spinning semi-compact spinning method, the roving is drafted and twisted by the front bottom roller nip of the original ring spinning machine, and the front rubber roller and the front bottom roller of the original ring spinning machine A draft zone and a weak twist zone are formed at the roller, and a semi-compact spinning device that can adjust the length of the traction zone and the length of the weak twist zone is installed downstream of the original front rubber roller 2 and the original front bottom roller 3 of the original ring spinning machine. The described semi-compact spinning device comprises a yarn drawing roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com