Steel-core aluminum deoxidizing agent blocks and method for producing the same

A technology for an aluminum deoxidizer block and a manufacturing method, which is applied in the field of steelmaking and can solve the problems of complex production of steel core aluminum deoxidizer block, unstable aluminum content, rough appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

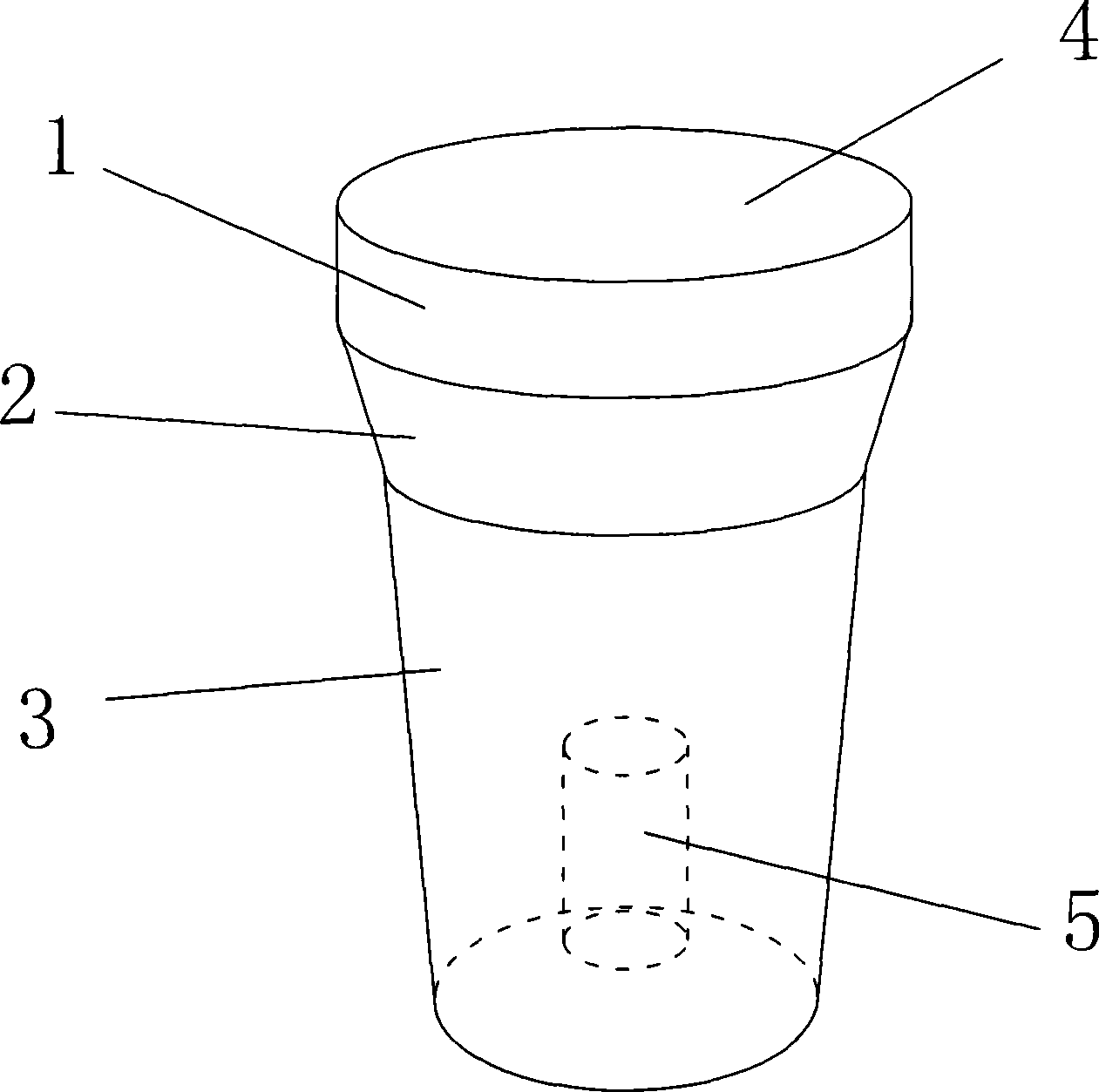

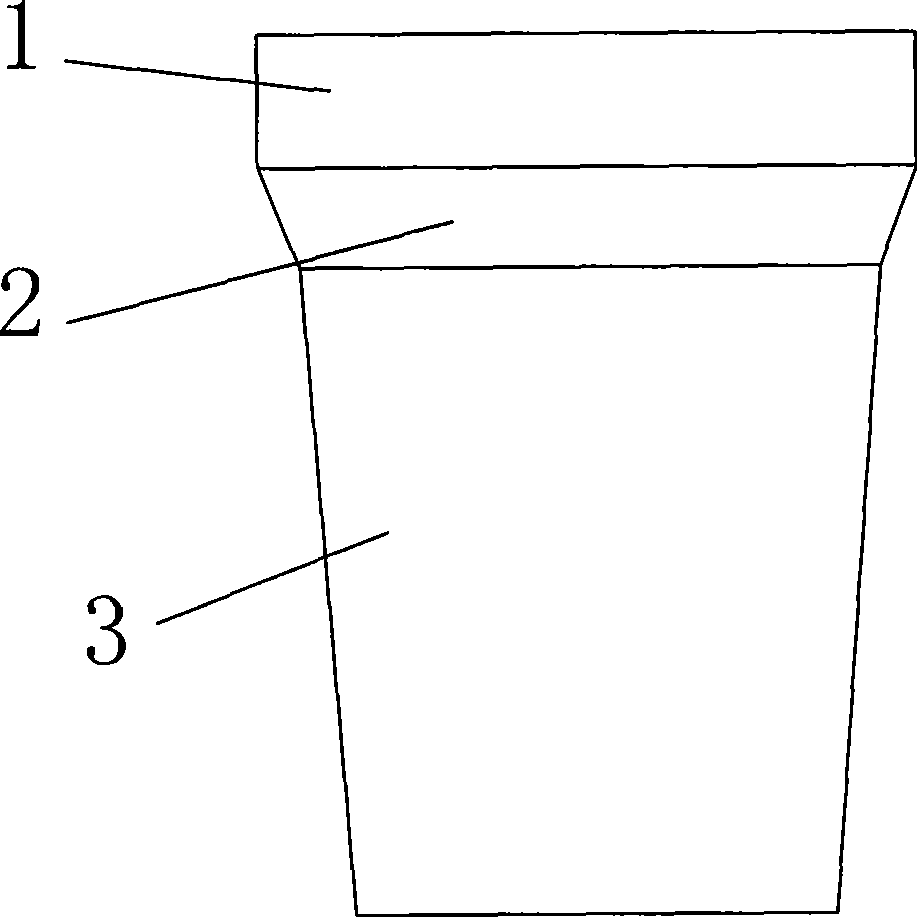

[0008] Embodiment 2: The steel-cored aluminum deoxidizer block of the present invention is composed of an outer layer and an inner layer, the outer layer 4 is wrapped outside the inner layer 5, there is no gap between the inner layer and the outer layer, and the outer layer is composed of the lower layer 3, the transition layer 2 and the upper layer 1 Composition, there is a transition layer on the upper end of the lower layer, and an upper layer on the upper end of the transition layer. The preparation method is to add 200kg of pure aluminum ingots into the KGPS-200 / 1 intermediate frequency furnace, heat and melt to make aluminum liquid, and then add 0.4kg of fluoroaluminic acid Remove slag from sodium, purify aluminum water, inject 450g of purified aluminum water into the mold with a tool, pour clean aluminum water to the top of the lower layer of the mold, stop casting, put 550g steel core vertically into the clean aluminum water in the mold, and naturally After cooling, unm...

Embodiment 3

[0009] Embodiment 3: The steel-cored aluminum deoxidizer block of the present invention is composed of an outer layer and an inner layer, the outer layer 4 is wrapped outside the inner layer 5, there is no gap between the inner layer and the outer layer, and the outer layer is composed of the lower layer 3, the transition layer 2 and the upper layer 1 Composition, there is a transition layer on the upper end of the lower layer, and an upper layer on the upper end of the transition layer. The preparation method is to add 200kg of pure aluminum ingots to the KGPS-200 / 1 intermediate frequency furnace, heat and melt to make aluminum liquid, and add 0.6kg of sodium fluoroaluminate Remove slag, purify the aluminum water, pour 650g of purified aluminum water into the mold with a spoon, pour the aluminum water to the top of the lower layer of the mold, stop casting, put the 350g steel core vertically into the clean aluminum water in the mold, and naturally After cooling, unmold and ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com