Method for continuous producing dichlorohydrin and apparatus thereof

A technology of dichloropropanol and chlorination reaction, applied in the introduction of halogen preparation, organic chemistry, etc., can solve the problems of gasification loss, large consumption of HCl gas, long reaction time, etc., achieve easy recycling and reduce waste The amount of production and the effect of reducing waste water production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0037] The purpose of this embodiment 1-5 is in order to illustrate the influence of acetic acid concentration on the conversion rate of dichloropropanol, so only illustrate with one chlorination reaction. A 1 liter positive pressure reactor equipped with a stirring device, heating equipment, pressurized lines and components was used. Feed the feed mixture containing glycerol, aqueous hydrochloric acid and acetic acid in the amounts listed in Table 1 below into the above-mentioned reactor, and at a reaction temperature of 145° C. and a reaction pressure of 6 bar, by controlling the feed rate to be 10 ml / Minutes and the control reaction residence time are carried out the first chlorination reaction under the condition of 1.5 hours, observe that acetic acid concentration is compared to dichloropropanol conversion, and experimental result is as shown in table 1.

[0038] Table 1

[0039] Example number 1 2 3 4 5 Glycerin (g) 46 46 46 46 46 Aqueous ...

Embodiment 6-10

[0042]The purpose of this embodiment 6-10 is in order to illustrate the influence of hydrochloric acid aqueous solution concentration on the conversion rate of dichloropropanol, so only illustrate with one chlorination reaction. A 1 liter positive pressure reactor equipped with a stirring device, heating equipment, pressurized lines and components was used. The feed mixture comprising glycerol, aqueous hydrochloric acid solution and acetic acid in the amounts listed in Table 2 below was fed into the above-mentioned reactor, and at the reaction temperature shown in Table 2 and the reaction pressure of 6 bar, by controlling the feed rate to 15 milliliters / minute and control reaction residence time is that under the condition of 1.0 hour, carry out chlorination reaction for the first time, observe the presence of hydrochloric acid aqueous solution and compare dichloropropanol conversion, experimental result is as shown in table 2.

[0043] Table 2

[0044] Example numb...

Embodiment 11

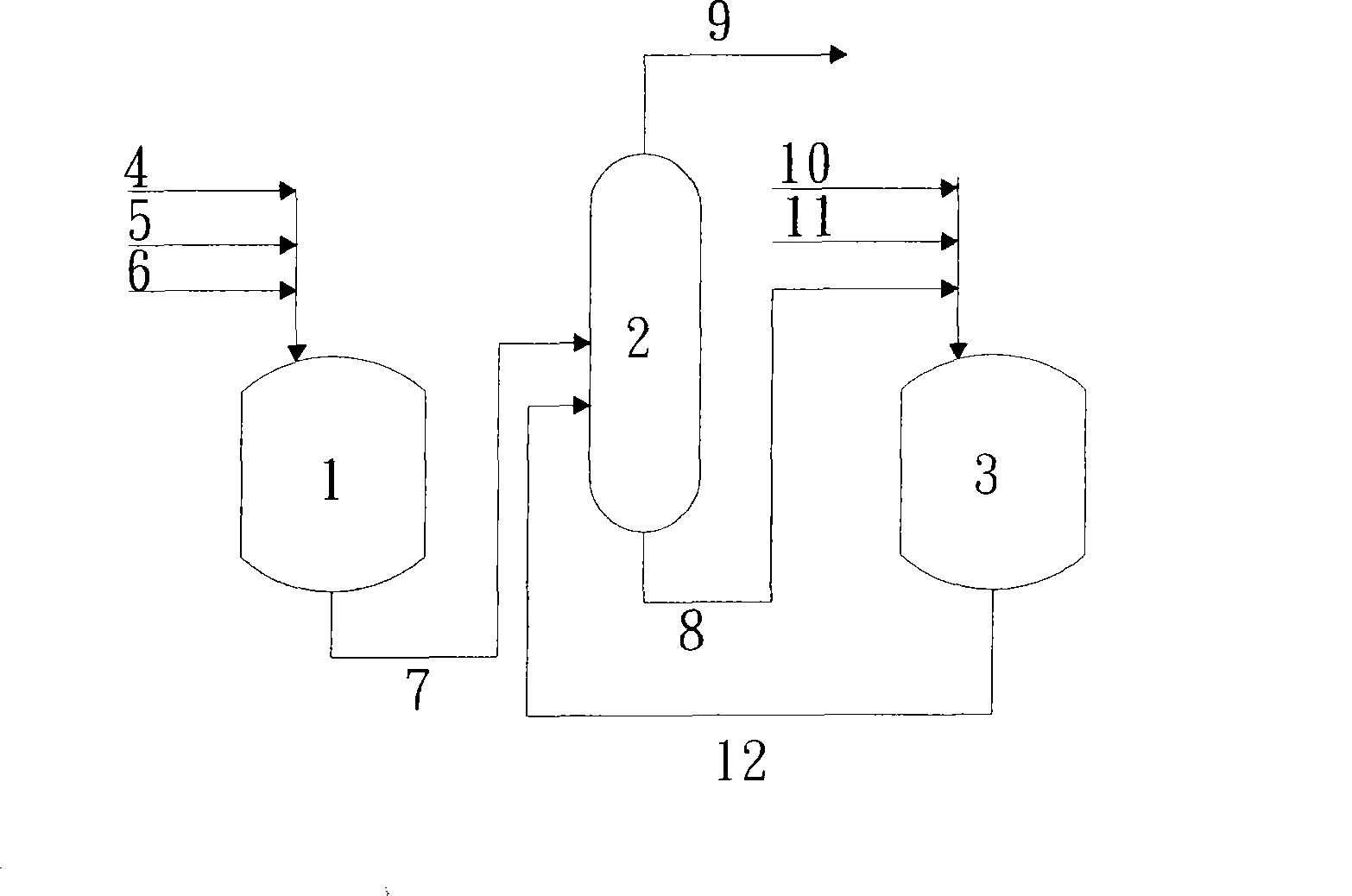

[0048] use figure 1 In the shown reaction device, the hydrochloric acid aqueous solution and the acetic acid that will comprise glycerin, the concentration are 32% by weight respectively with the speed of 1.12 milliliter / minute, 9.71 milliliter / minute and the speed of 0.67 milliliter / minute via the acetic acid feed pipe 4, hydrochloric acid aqueous solution feed Pipe 5 and glycerol feed pipe 6 are fed into the first reactor 1 (capacity is 1 liter), and simultaneously with the same speed of feeding rate, the material is discharged to maintain a fixed liquid level in the reactor (in this embodiment, the output The speed should be 1.12+9.71+0.67 ml / min). The first chlorination reaction was carried out at a reaction temperature of 140° C., a reaction pressure of 6 bar, and a reaction residence time of 1.5 hours. After the reaction, the product is fed into the middle section of the distillation tower 2 through the discharge pipe 7, and the product dichloropropanol is collected fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com