Medicine bottle operation needle and processing method thereof

A technology of operation and medicine bottle, which is applied in the field of medical equipment, can solve the problems affecting the quality of medicine use, and achieve the effect of eliminating the phenomenon of rubber plug particles in the liquid, avoiding loss, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

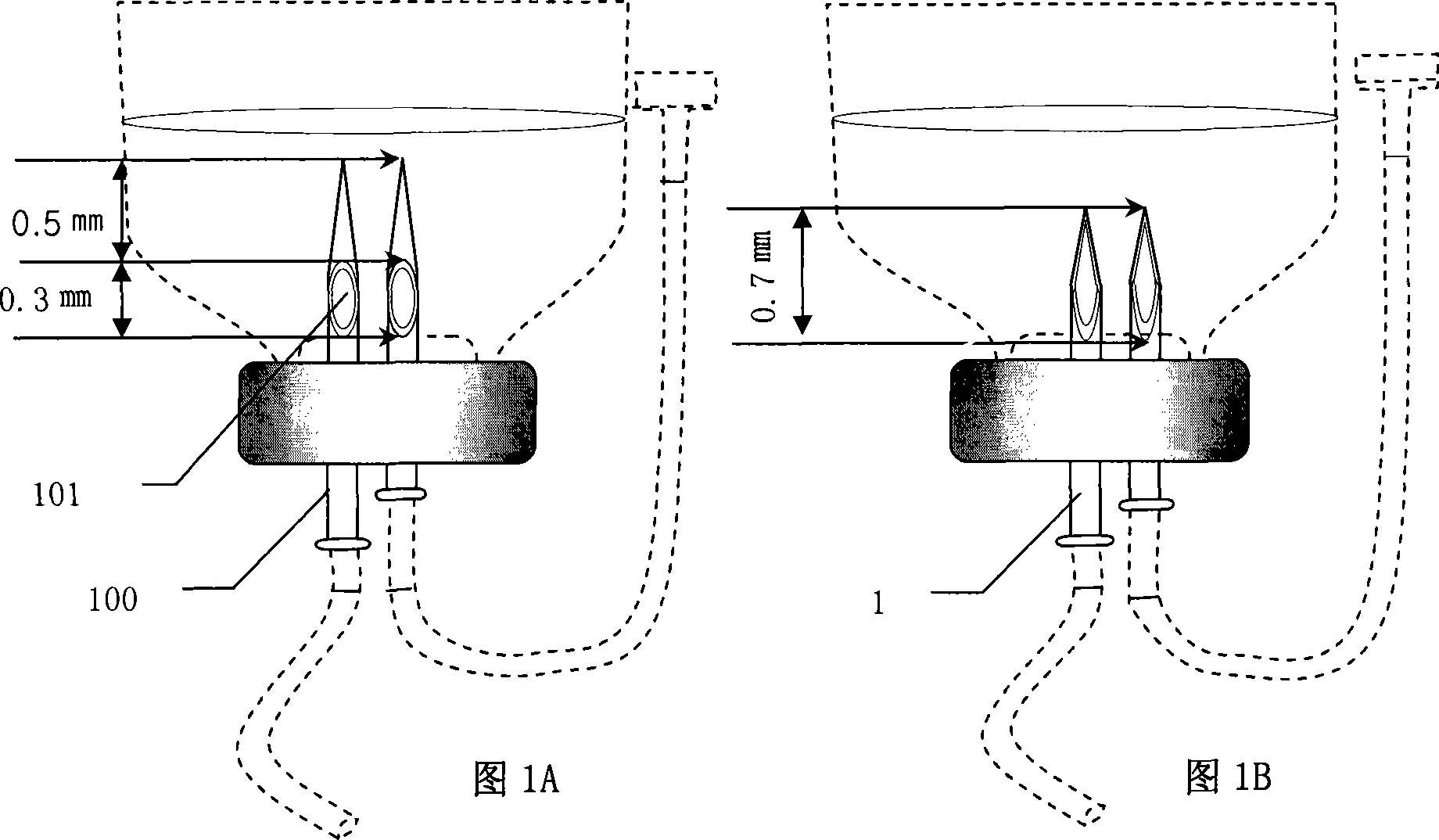

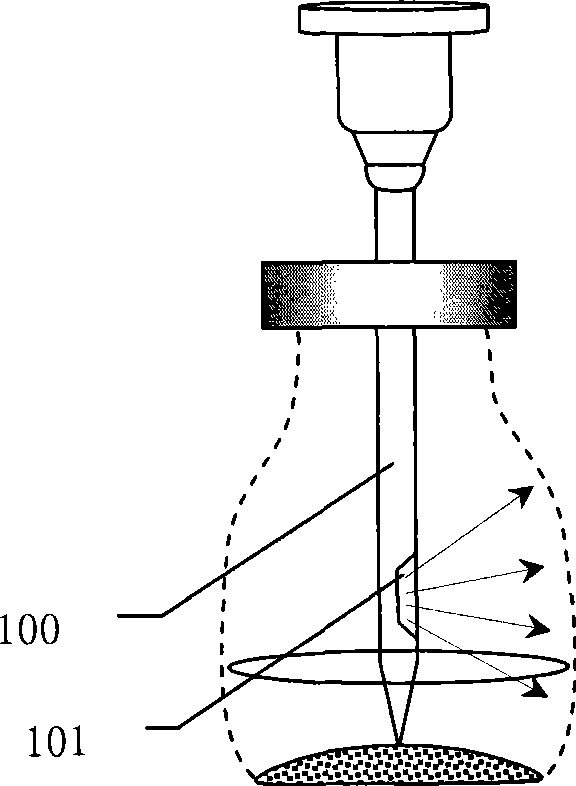

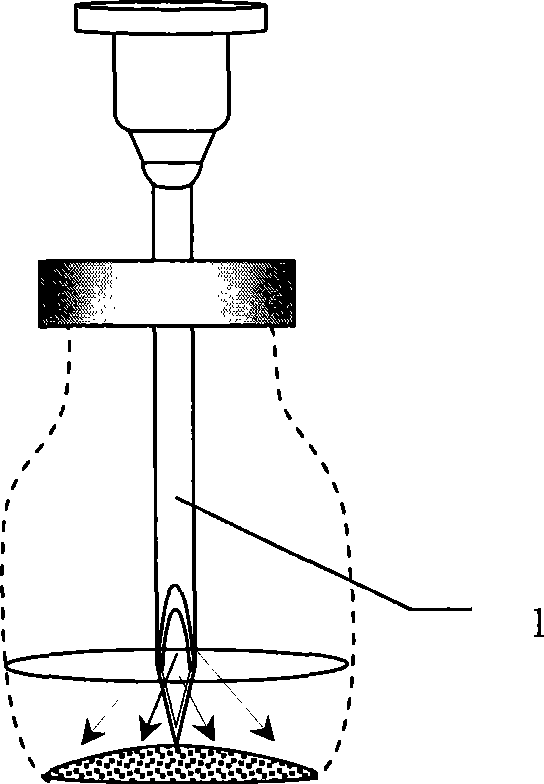

[0031] The present invention is mainly realized by improving the needle structure of operation needles such as the existing infusion bottle intake needle (referred to as the intake needle), the infusion bottle dripping needle (referred to as the bottle insert needle), and the dispensing dilution injection needle (referred to as the dispensing needle). The purpose of the invention.

[0032] For the needle structure of the working needle of the present invention, see Figure 5 As shown, first of all, the needle tip of the needle 1 is no longer closed but in an open state. The front end of the needle 1 is provided with a second inclined surface 12 close to the needle tip and a first inclined surface 11 thereafter. The first inclined surface 11 is a needle tube 14 (see Figure 3A~3C ), the first inclined surface 11 and the wall of the needle tube 14 are between 15 degrees, and the second inclined surface 12 is between 18 degrees and the wall of the needle tube; wherein, the entire edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com