Soybean curd discharging device for bean products production device

A technology for production equipment and bean products, which is applied in the field of bean product production equipment, can solve the problems of uncontrollable speed, low production efficiency, and reduced quality, and achieve the effect of increasing the discharge speed and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

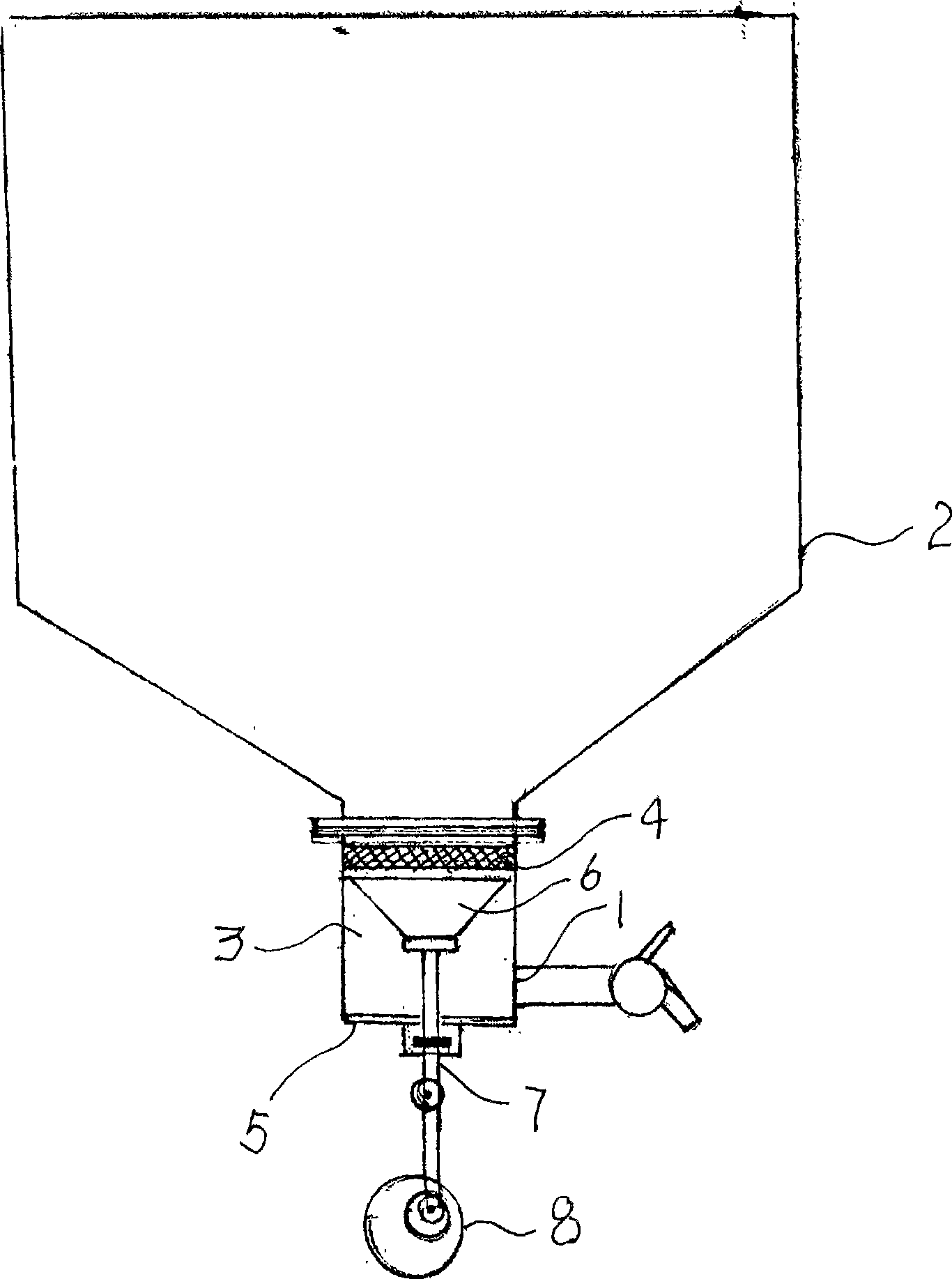

[0009] As shown in the figure, the lower brain device used for soybean product production equipment according to the present invention includes a material holding cylinder 2 provided with a discharge port 1; The discharge port 1 is arranged at the lower part of the side wall of the brain stirring chamber 3; in the brain stirring chamber 3, a screen 4 is horizontally arranged at the position where the brain stirring chamber 3 connects with the material storage cylinder 2, and a screen 4 is arranged between the screen 4 and the bottom of the brain stirring chamber. A piston 6 that reciprocates up and down is arranged between the walls 5 . The piston 6 has an inverted cone structure. The piston rod 7 of the piston 6 extends out of the bottom wall 5 of the churning ventricle and is connected with the driving mechanism 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com