Automatic/semi-automatic measurement method for depth-hardness curve of rolled steel and device thereof

A measurement method and a technology of a measurement device, which are applied in the direction of testing metals, material inspection products, and testing material hardness, etc., can solve problems such as error-prone, affecting the accuracy of results, and low efficiency, so as to improve displacement accuracy, improve work efficiency, The effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

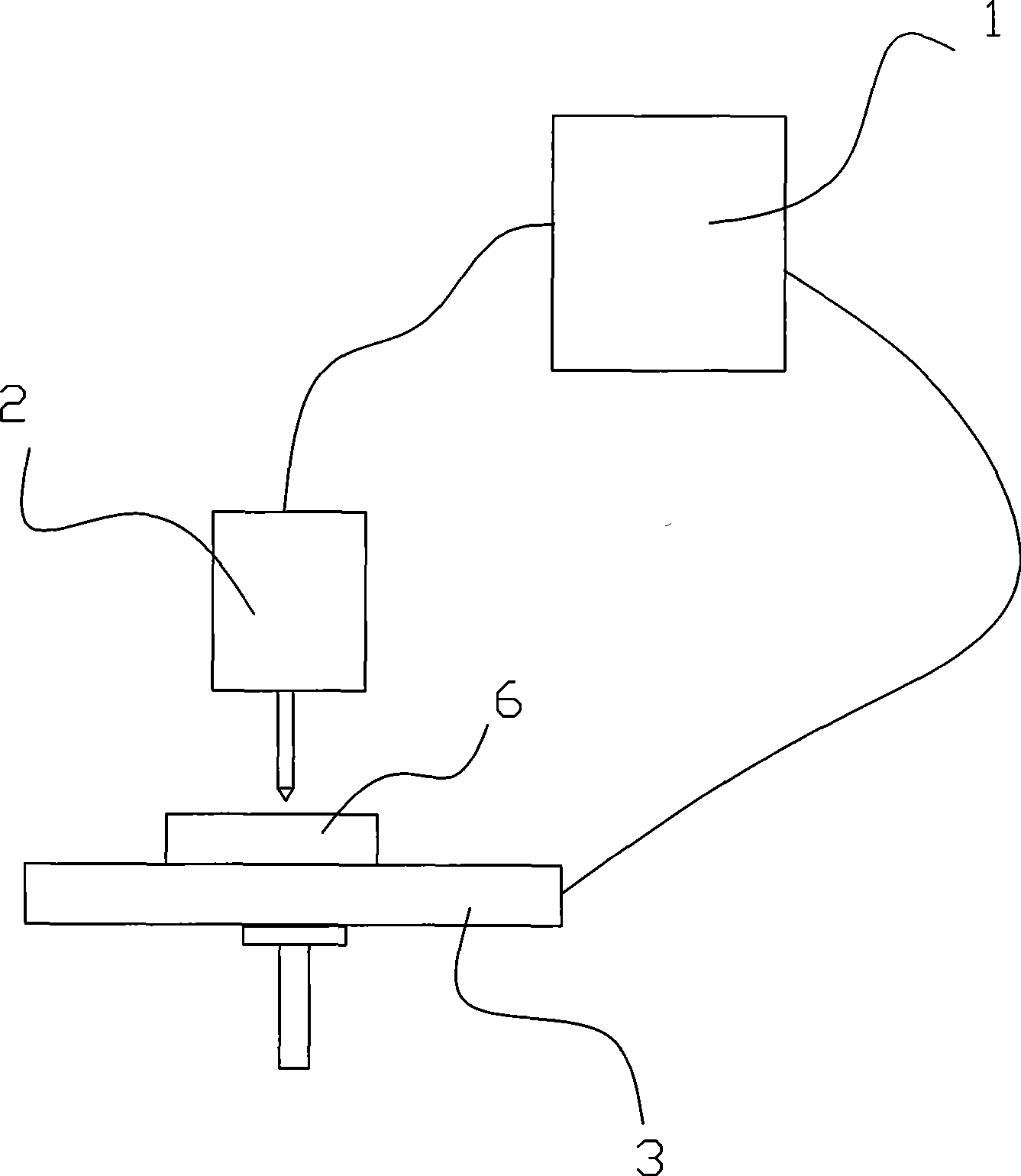

[0103] Such as figure 1 As shown, the automatic measuring device of the present invention includes a computer 1 , a hardness tester 2 and a specimen clamping mechanism 3 .

[0104] Among them, computer 1 is a computer equipped with software for controlling the plane movement of the specimen clamping mechanism, hardness tester startup control and data reading, and hardness tester 2 is an ordinary desktop hardness tester.

[0105] The computer 1 is electrically connected with the data communication interface (such as RS232 port) on the hardness tester 2, controls the displacement of the specimen clamping mechanism and automatically collects the hardness measurement data into the memory in the computer.

[0106] The specimen clamping mechanism 3 adopts an electric translation platform, which is an existing technology, equipped with a standard RS232 interface, connected with a computer, and can control the displacement through the computer with the control software. The electric ...

Embodiment 2

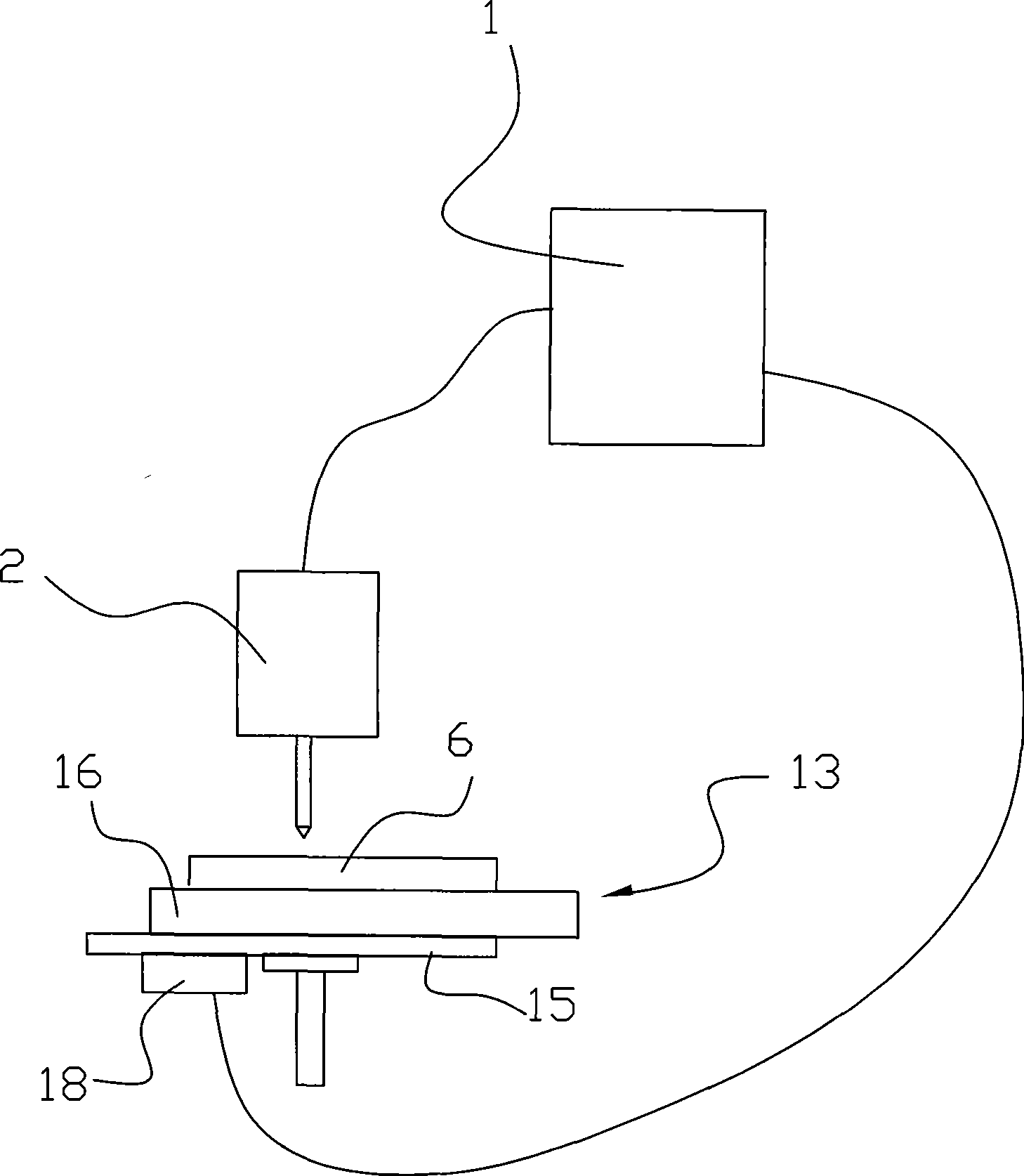

[0112] Such as figure 2 As shown, in order to realize the semi-automatic measurement device of the present invention, it includes a computer 11, a hardness tester 12, and a specimen clamping mechanism 13.

[0113] Among them, the computer 1 is a computer equipped with special software, the hardness tester 2 is an ordinary desktop hardness tester, and the computer 1 is connected with a special computer interface (such as an RS232 interface) on the hardness tester 2 to collect the hardness measurement data on the computer.

[0114] The displacement and hardness values obtained by the computer 1 can be processed by software to automatically obtain the required measurement curve.

[0115] The specimen clamping mechanism 13 includes a fixed seat 15 and a V-shaped groove 16 , and the V-shaped groove 16 is horizontally matched with the fixed seat 15 . The fixing seat 15 is fixed under the pressure head of the hardness tester, the test piece 6 is fixed on the V-shaped groove 16, a...

Embodiment 3

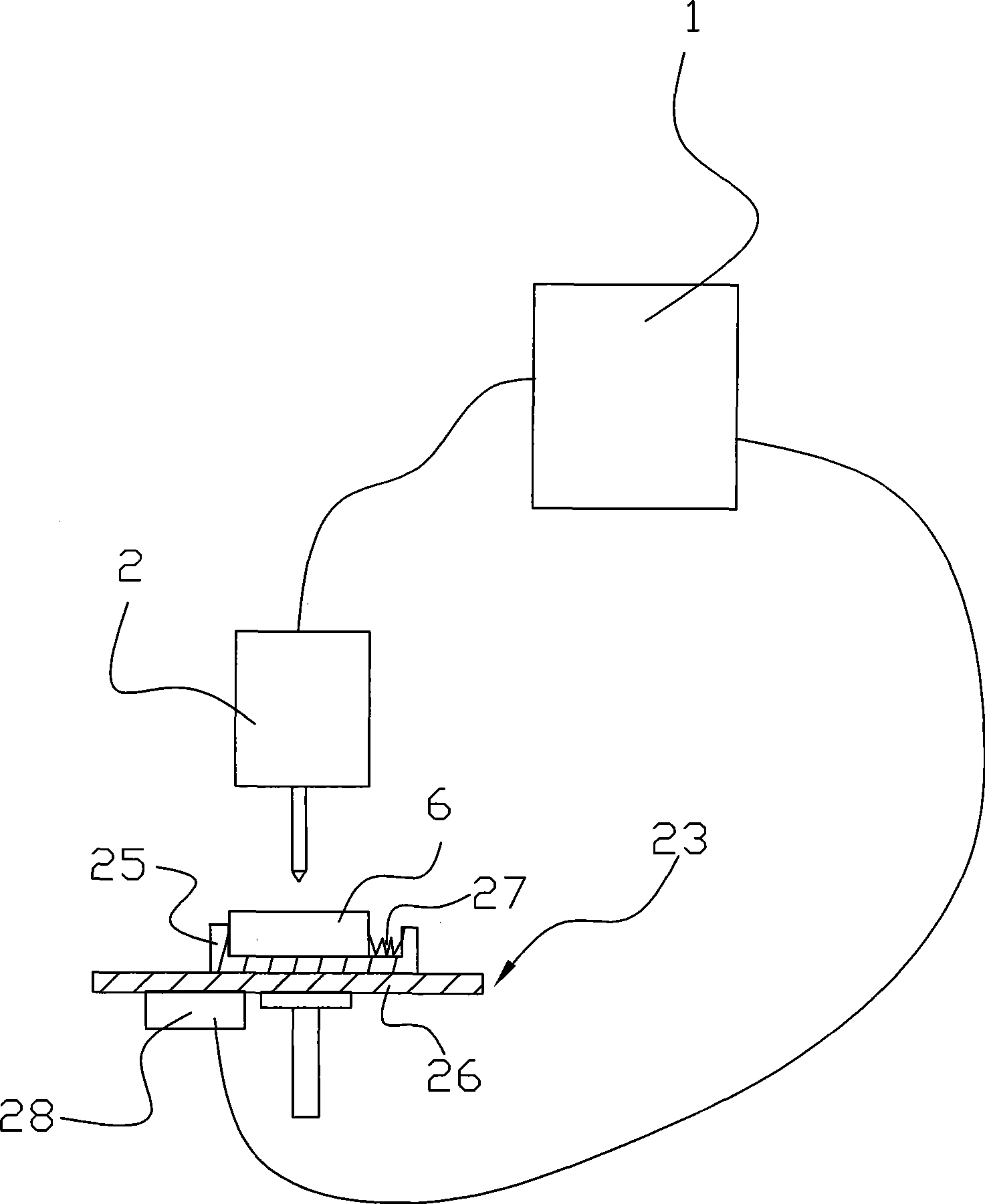

[0120] Such as image 3 As shown, the specimen clamping mechanism 23 is composed of a fixed seat 25 and a chute 26, the chute 26 and the fixed seat 25 are horizontally slidingly matched, the fixed seat 25 is fixed under the pressure head of the hardness tester, and there is a rectangular groove above the chute 26 , a spring 27 is installed at one end of the groove, and the test piece 6 is put into the groove, and the spring 27 at one end realizes pressing and fixing. The movement of the test piece is realized by manually moving the chute 26 . An electronic displacement measuring device 28 is installed on the fixed frame, and the device has a special-purpose computer interface (such as an RS232 interface), which transmits the displacement data of the specimen movement to the computer;

[0121] Then use the dedicated computer interface (such as RS232 interface) on the hardness tester to transmit the hardness measurement data to the computer.

[0122] The computer software uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com