Coating density ultrasonic measurement method based on pressure reflection coefficient phase spectrum

A technology for sound pressure reflection coefficient and ultrasonic measurement, which is applied in measurement devices, specific gravity measurement, instruments, etc., and can solve problems such as laboratory research only and expensive laser ultrasonic systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

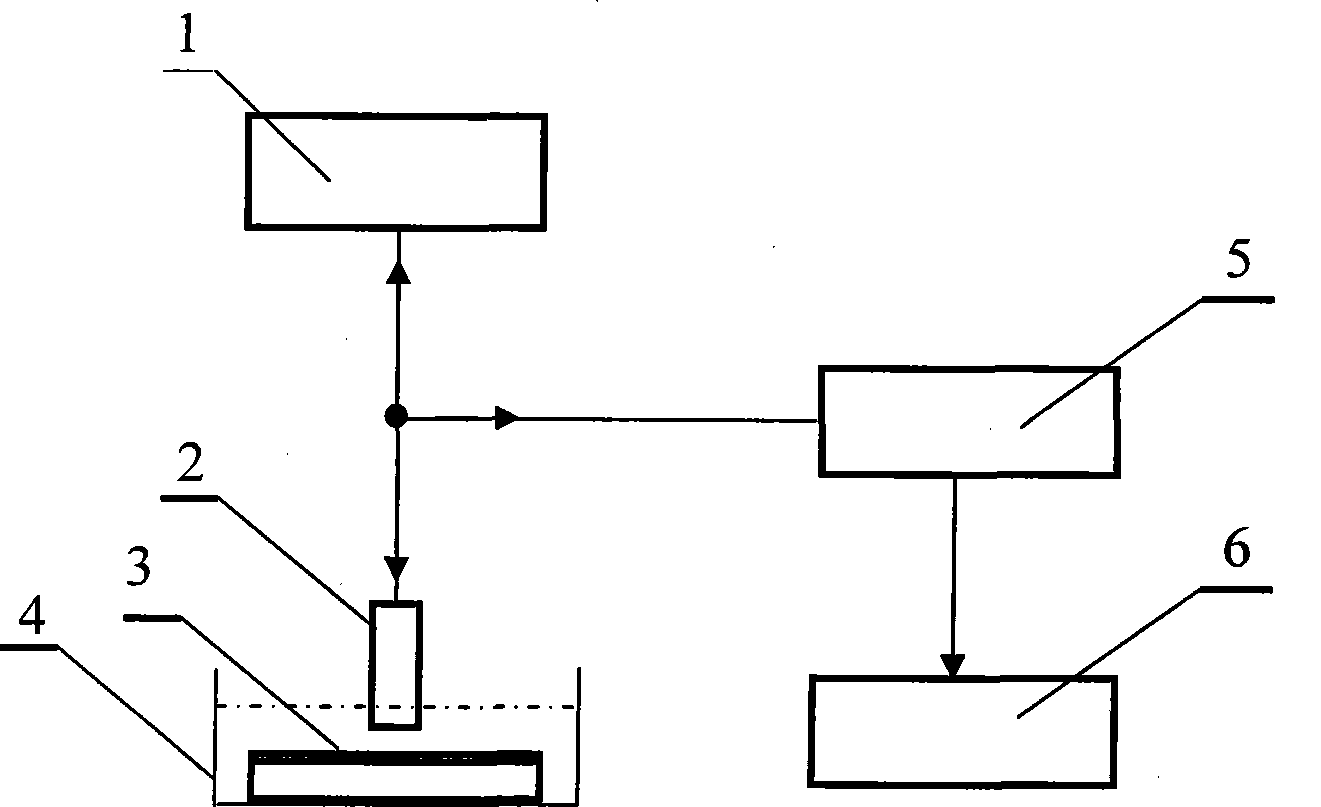

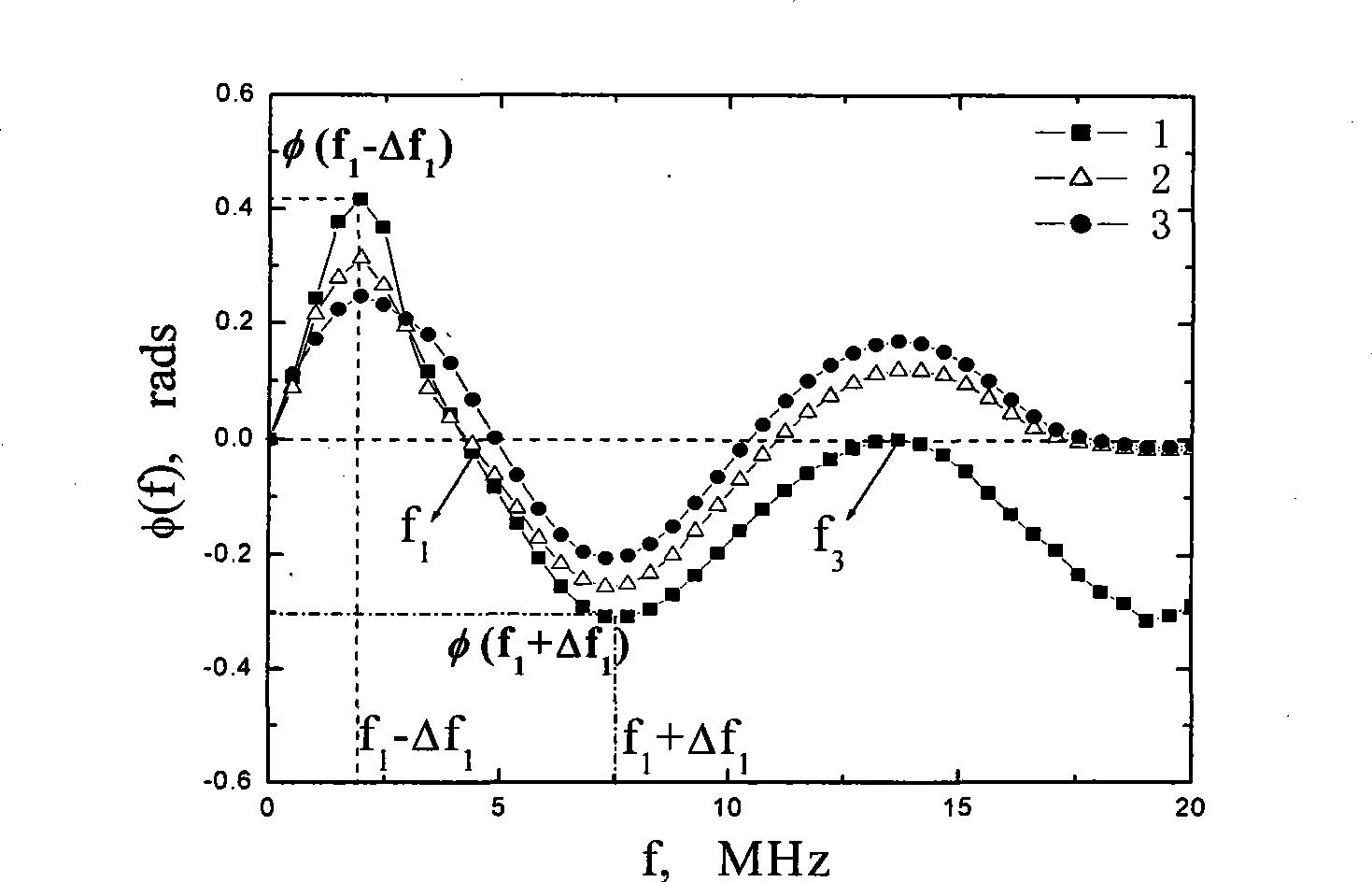

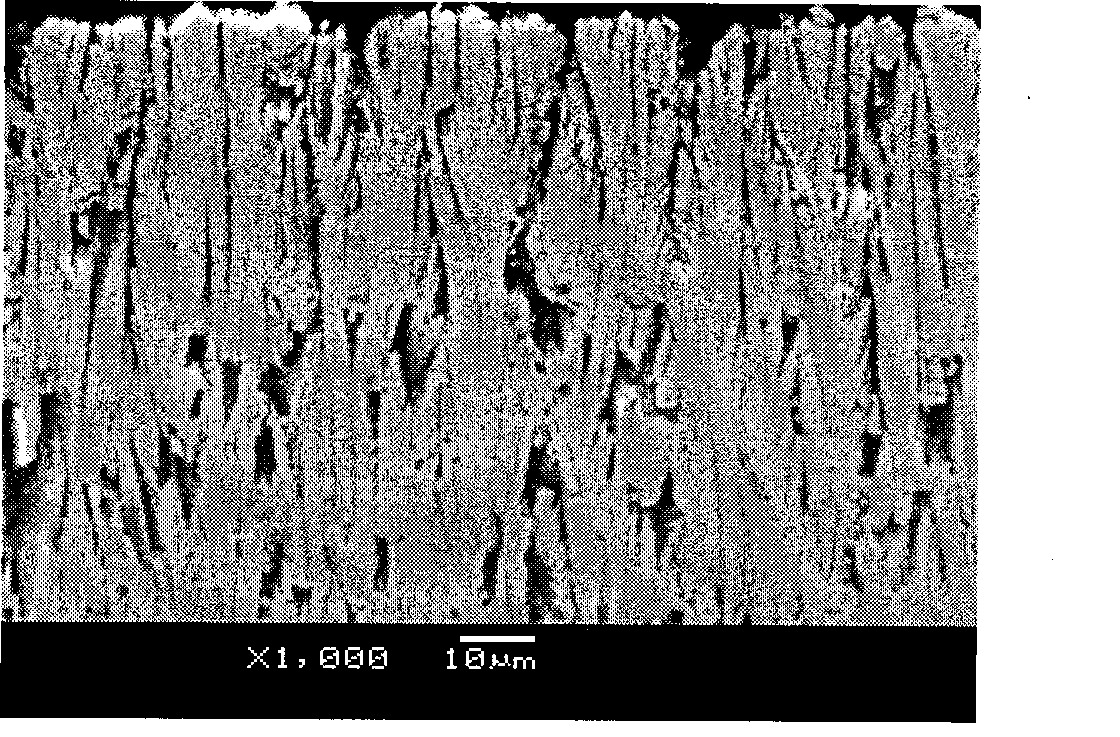

[0023] figure 1 After system connection and instrument calibration of the measurement device shown, with the help of ultrasonic flaw detector 1, an ultrasonic narrow pulse water immersion focusing probe with a wafer diameter of 11.4 mm and a nominal frequency of 10 MHz is used to direct the ZrO2 to be tested. 2 -7%Y 2 o 3 The coating sample 3 emits and receives ultrasonic waves (the coating sample 3 is placed in the water tank 4), and the waveform observation and data acquisition are completed with the help of the TDS-2012 digital oscilloscope 5 . Repeat the above process on the standard test block for ultrasonic flaw detection, and collect the surface echo signal of a standard test block. Utilize computer 6 to carry out FFT transformation respectively to the echo signal of tested coating and standard test block, obtain the real part and imaginary part data of corresponding signal; Part of the data is substituted into formula 1 to obtain the phase spectrum of the sound pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com