Suspension of a turbojet in an aircraft

A suspension device, turbojet technology, applied in the direction of power plant, power plant arrangement/installation, aircraft parts, etc., can solve the problems of reduced fuel efficiency, performance degradation, engine service life decline, etc., to reduce distortion and improve The effect of fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

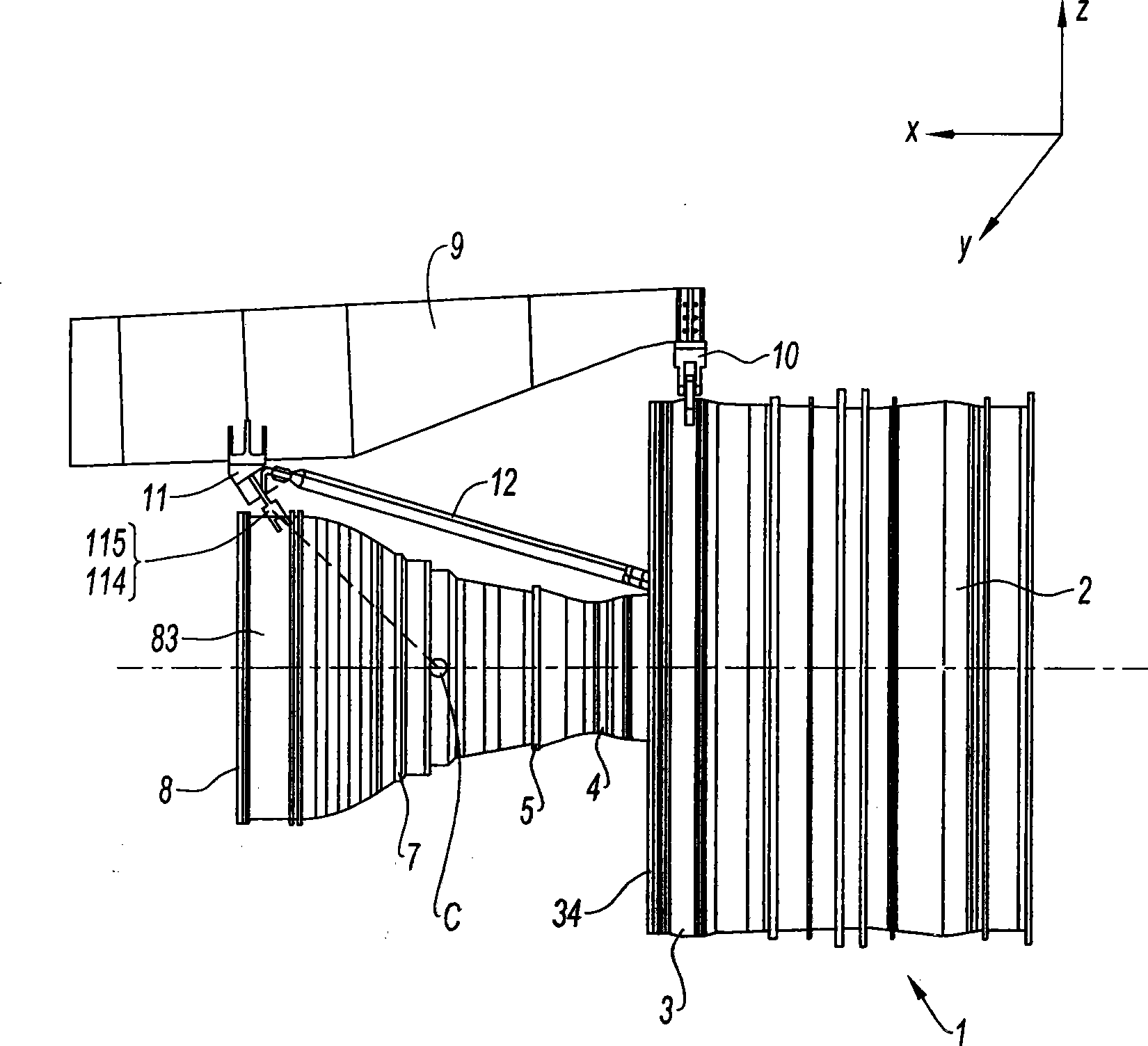

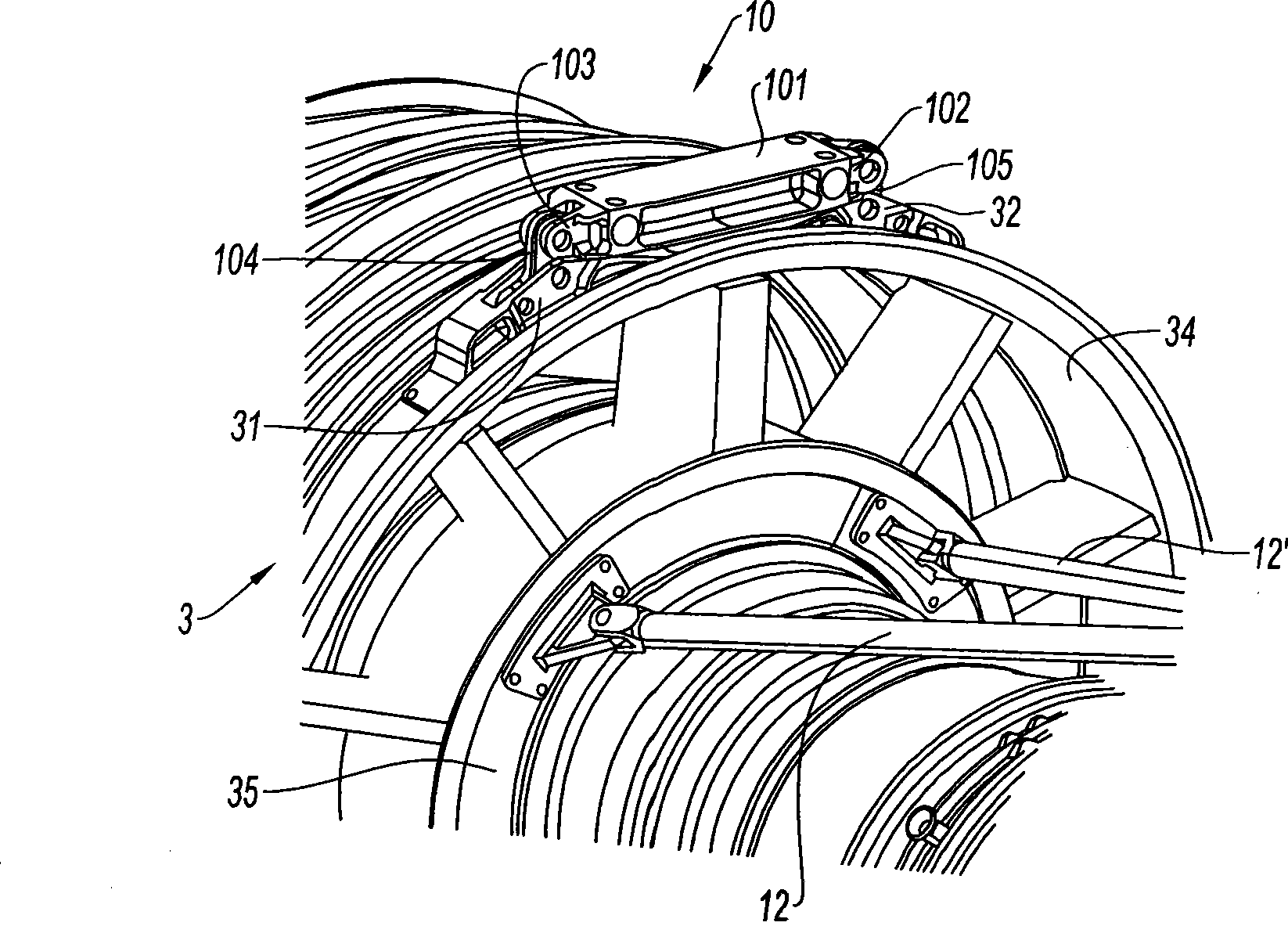

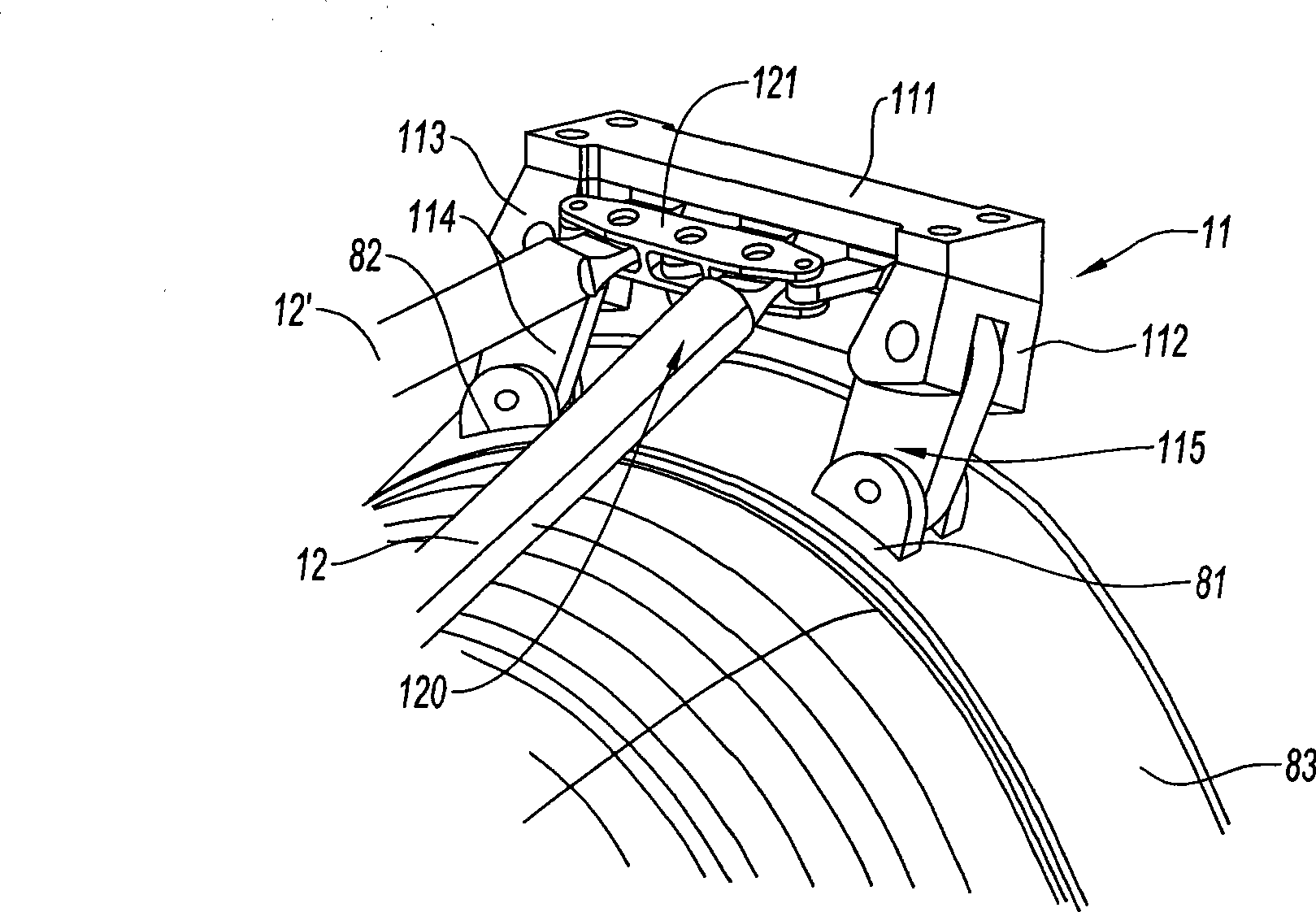

[0036] Such as figure 1 Shown, turbojet engine 1 is a turbofan type engine, and its fan case is shown in figure 2. The downstream of the fan casing 2 is the middle casing 3, and only the casing 34 can be seen in the figure. The upstream end of the air inlet is located at figure 1 Right side of drawing shown.

[0037] In the downstream position, the casing 4 of the compression section can be seen. The compression section communicates with the annular combustion chamber 5 . The turbine stage 7 is located downstream of the combustion chamber. At the extremity of the engine, there is an exhaust casing 8, which is a rear bearing support structure of known type. The coordinate system to which the axes and components of the individual forces and moments are directed includes an axis Ox parallel to the engine axis XX, which is assumed to be horizontal and extends from the upstream to the downstream end; the axis Oz is the vertical axis and the axis Oy is the transverse axis .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com