Transitional slide contact switch with push-press switch

A contact switch and sliding contact technology, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of large-scale switches, large pressing strokes, and difficulty in obtaining operating tactile sensations, and achieve the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

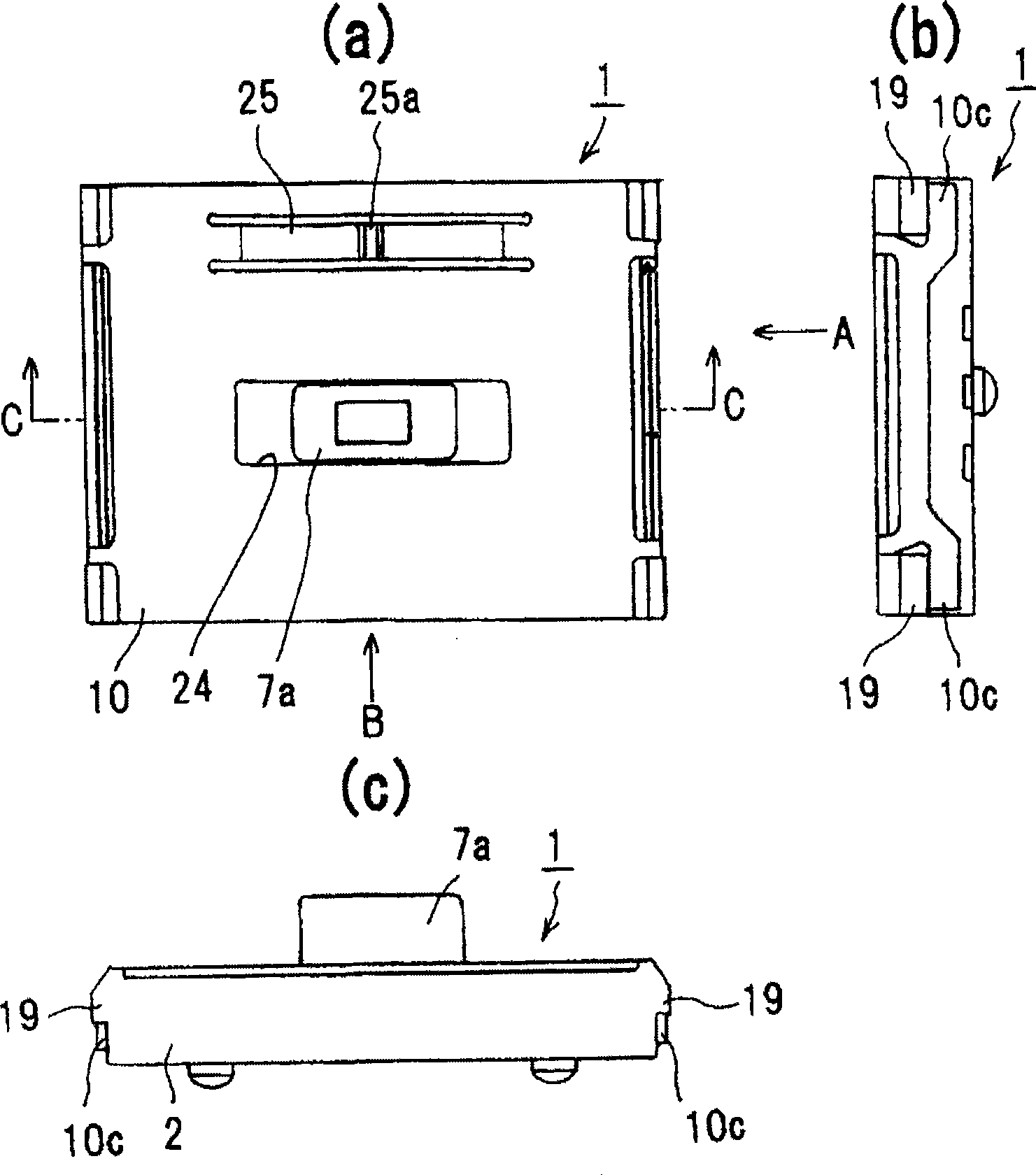

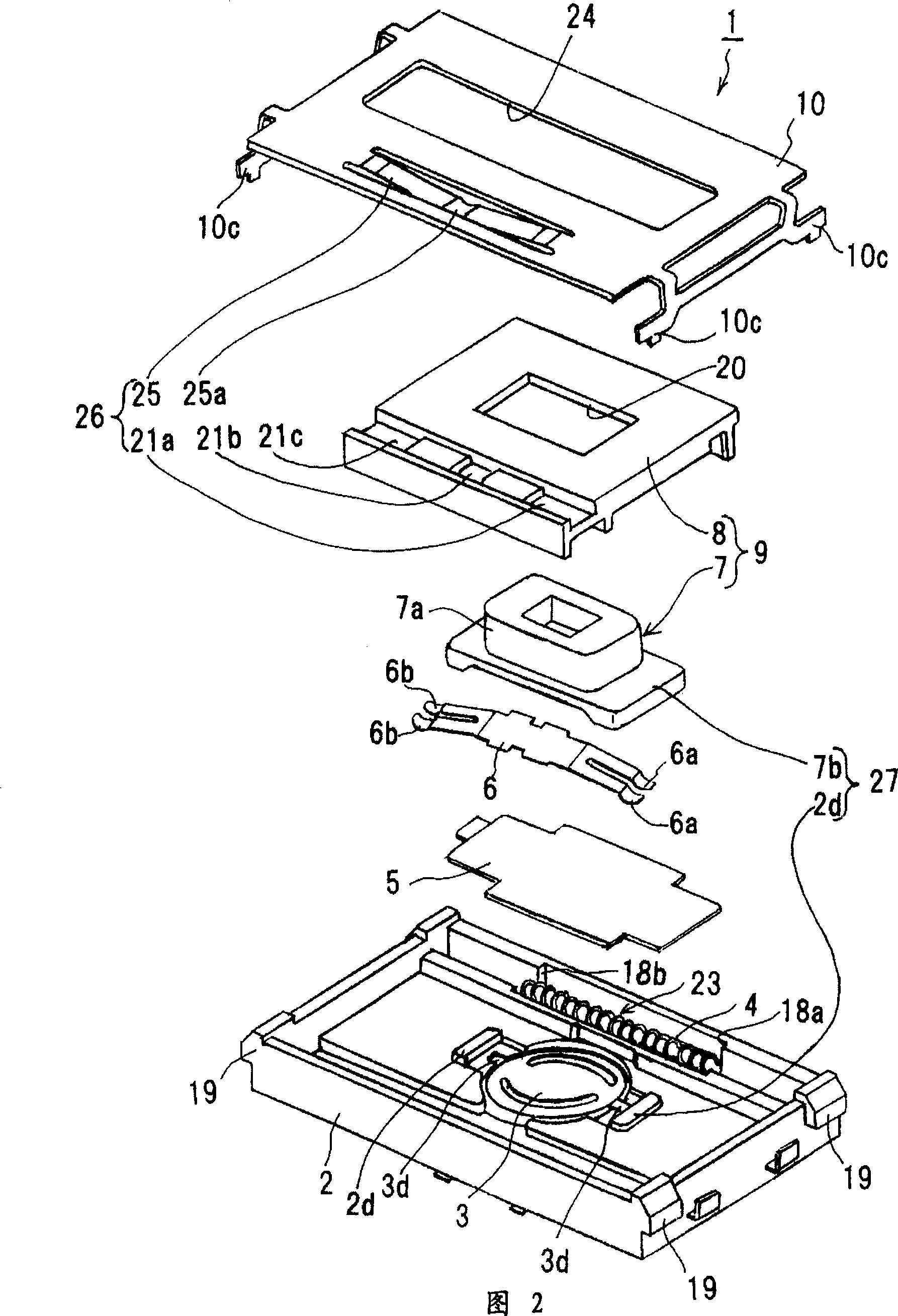

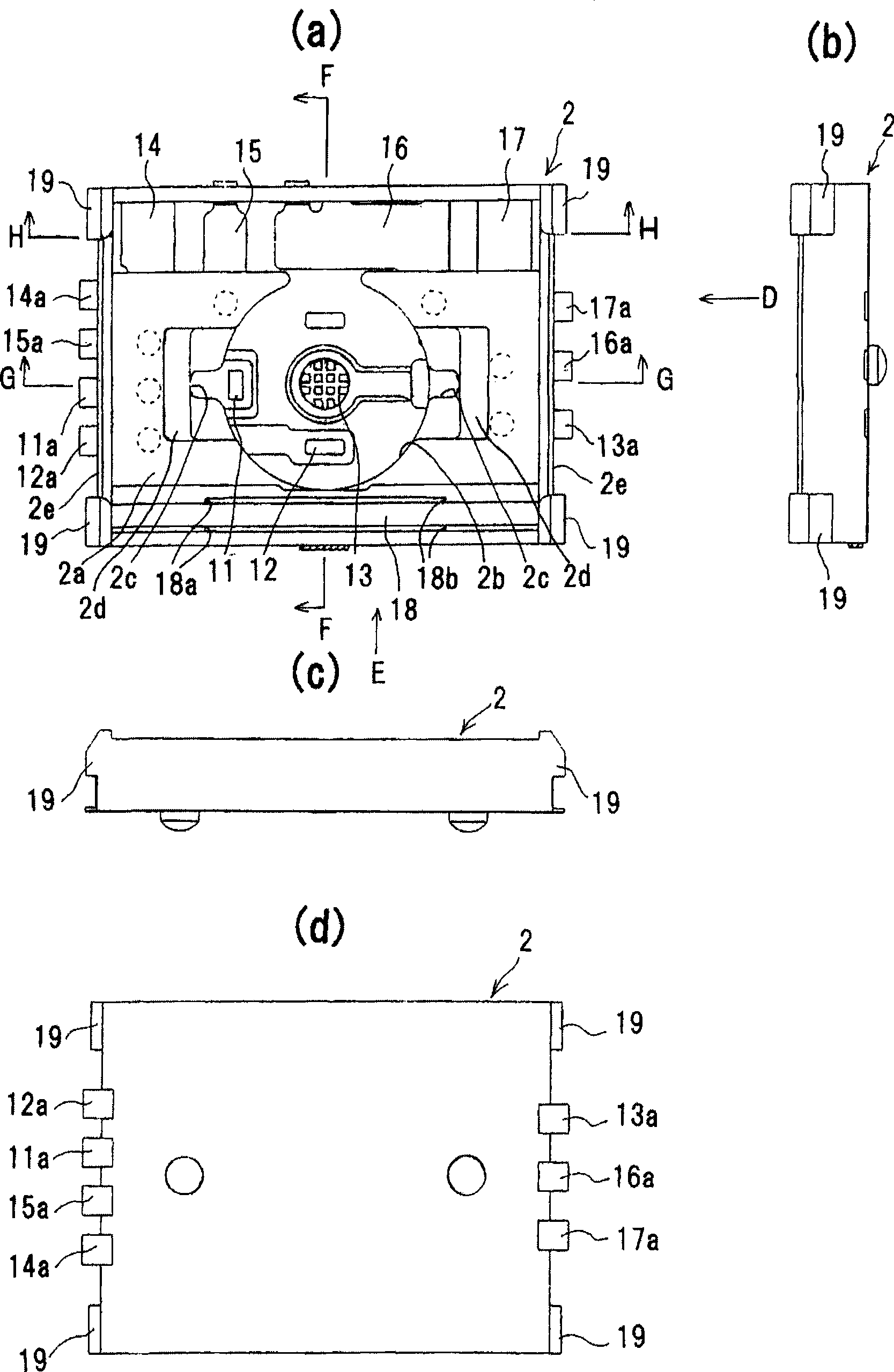

[0043] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. This embodiment is suitable for a sliding displacement contact switch with a push switch provided with a two-stage pressing mechanism. figure 1 It is a figure showing the appearance of the sliding contact switch with push switch, and Fig. 2 is an exploded perspective view of main parts of the slide contact switch with push switch, image 3 and Figure 4 It is a figure which shows a base part. First, the structure of the slide-displacement contact switch with push switch related to the present embodiment will be described.

[0044] In Fig. 2, the sliding displacement contact switch 1 with the push switch mainly includes: a base body 2; a butterfly-shaped movable contact piece 3 which constitutes a two-stage pressing mechanism together with a plurality of fixed terminals for pressing described later; The coil spring 4 of the return mechanism 23; the insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com