Multi-overflow circle tower plate

A multi-overflow, annular technology, applied in fractionation and other directions, to achieve the effect of reducing equipment cost, reducing pressure drop, and improving tray efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

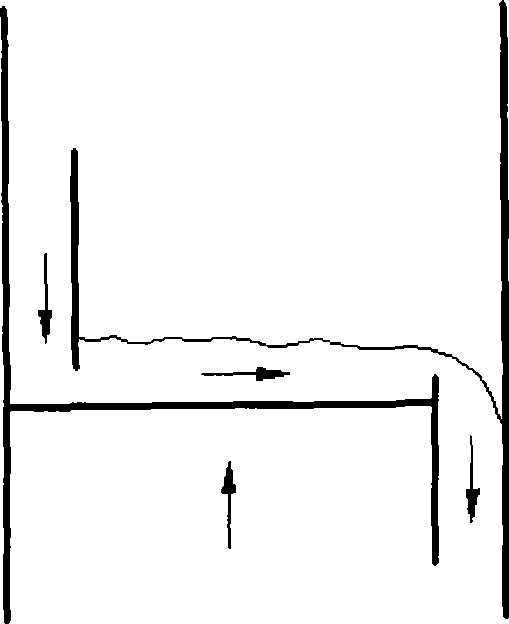

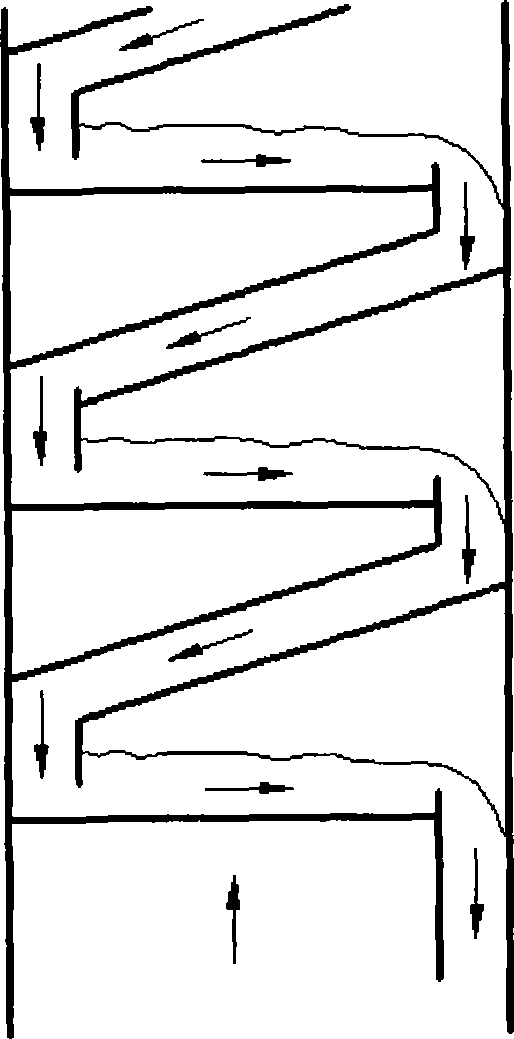

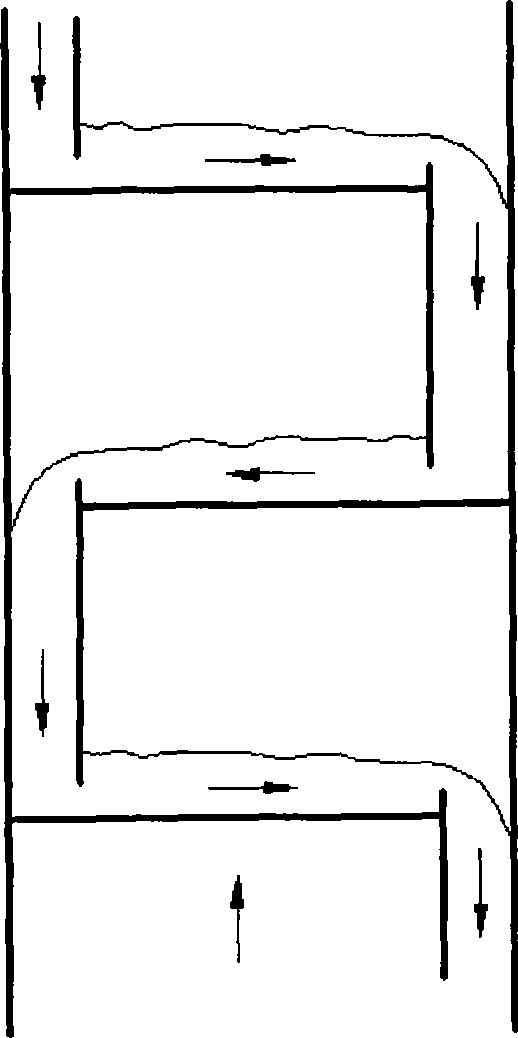

Method used

Image

Examples

Embodiment 1

[0052] Example 1, air separation plant model KOD-900 type high-purity nitrogen equipment medium nitrogen tower, the design parameters of the tower: the number of overflows is 2, the diameter of the tower body is 600mm, the diameter of the central support tube is 200mm, and the theoretical plate is 43 The actual tray is 60; the test run report shows that the composition of nitrogen at the 50th actual tray has reached the design value, the total pressure drop of the tower is basically consistent with the design value, and the tower can still operate stably under the working condition of 34%. That is to say, compared with the conventional design, the efficiency of the whole tower is increased by 20%, the pressure of each theoretical plate is reduced by 20%, and the ability to adjust the load can reach 34% of the working condition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com