Detachable locking rod

A split-type, stable rod technology, applied in the direction of fixator, internal fixator, internal bone synthesis, etc., can solve the problems of inability to change the spacing and the angle of the screw, up and down sliding, inconvenience, etc., to achieve easy revision and change, prevent The effect of sliding up and down for easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

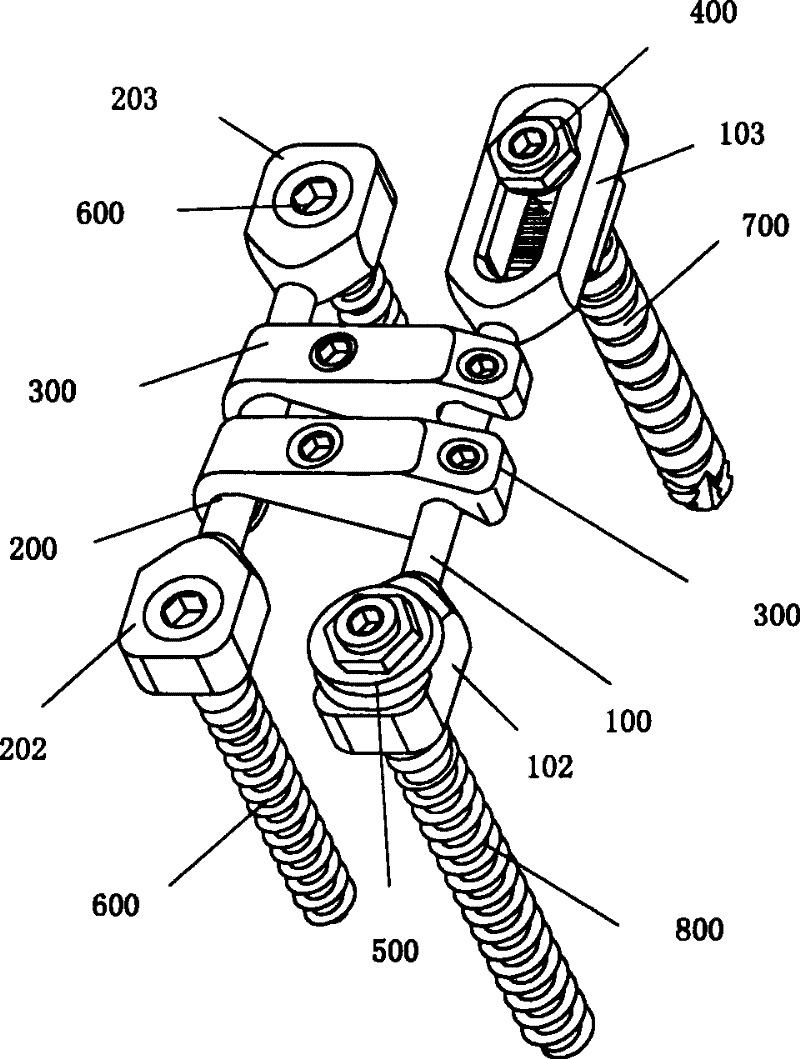

[0026] figure 1 The three-dimensional structure of an embodiment of the split locking rod of the present invention is shown. The split-type locking rod combines the strengths of the nail rod and nail-board system. The main body of the structure adopts a double nail rod structure, with a main support rod 100 and a stabilizing rod 200; and two transverse connections are arranged between the two rods 100 and 200 device 300.

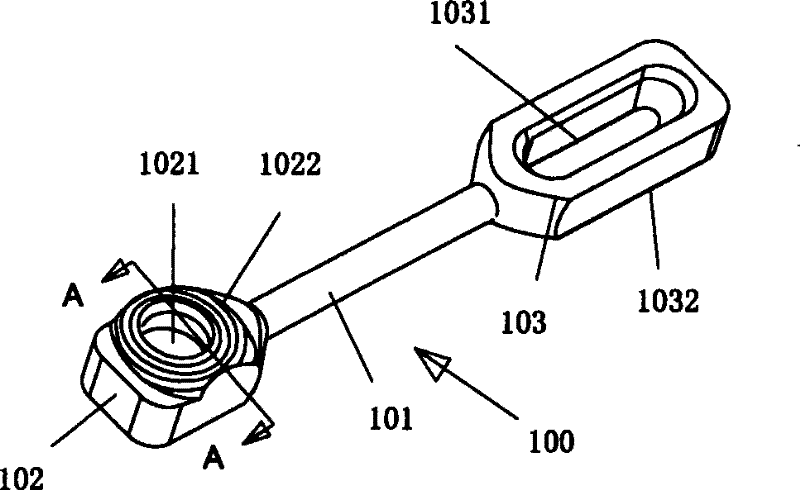

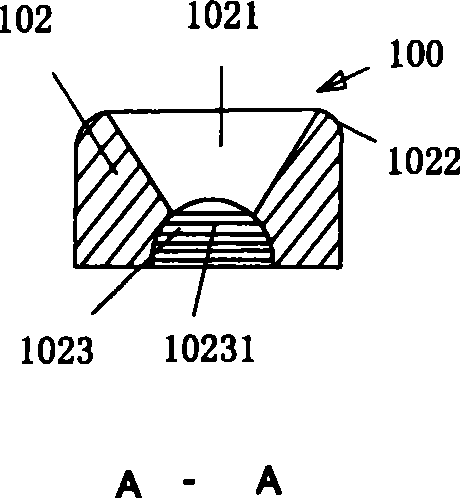

[0027] Please see diagram 2-1 , the middle section of the main support rod 100 is a round rod 101, there is a plate-shaped palm 102 at the proximal end, and a plate-shaped palm 103 at the far end. A through hole 1021 is provided on the palm portion 102 at the proximal end of the main support rod 100 . Please see Figure 2-2 The through hole 1021 of the palm portion 102 at the proximal end of the main support rod 100 has a conical hole section with the big end outside and a hemispherical hole section 1023 with the big end outside. The palm portion 102 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com