Method for preventing static electricity during down processing and device thereof

An anti-static and down technology, which is applied in clothing and other fields, can solve the problems of increasing energy consumption, reducing the production efficiency of down processing equipment, and excessive static electricity, so as to achieve the effects of reducing static electricity, eliminating static electricity, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

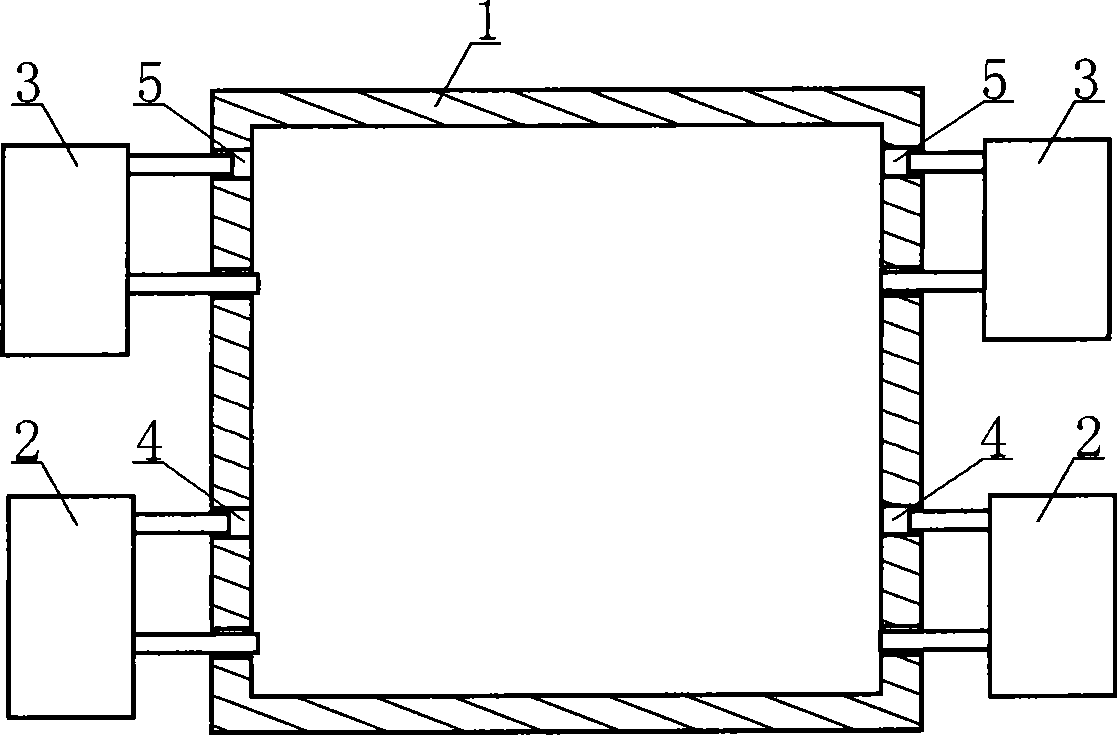

[0012] Such as figure 1 As shown, an anti-static method for down processing is: make the temperature change in the down-sorting box small, control the temperature between 23°C and 27°C, and at the same time keep a certain humidity in the down-sorting box, when the temperature is at 22 When the temperature is below ℃, use the constant temperature and moisturizing device to spray water vapor into the fleece sorting box to increase the temperature in the fleece sorting box to ensure that the temperature in the fleece box is above 23°C. Spray water mist to make the temperature in the cashmere box fall back, and ensure that the temperature in the cashmere box is below 27°C.

[0013] The device used for realizing the antistatic method of down processing includes a down-separating box 1, and the down-separating box 1 is provided with a constant temperature and moisturizing device. The constant temperature moisturizing device is composed of a steam generator 2 and a water mist genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com