Lens module

A technology for lens module and lens retention, which is applied in installation, optics, television, etc., can solve problems such as complex structure of lens module, uncertain magnetization direction of excitation components, and difficult control of friction force, etc., to achieve automatic focusing and zooming functions, The number of components is simple and reliable, and the effect of less friction joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Figure 5 The basic configuration of the lens module according to Example 1 of the present invention is shown, (a) is an external plan view viewed from the upper surface direction, and (b) is a diagram related to a side sectional view in the direction of line A-A of (a) .

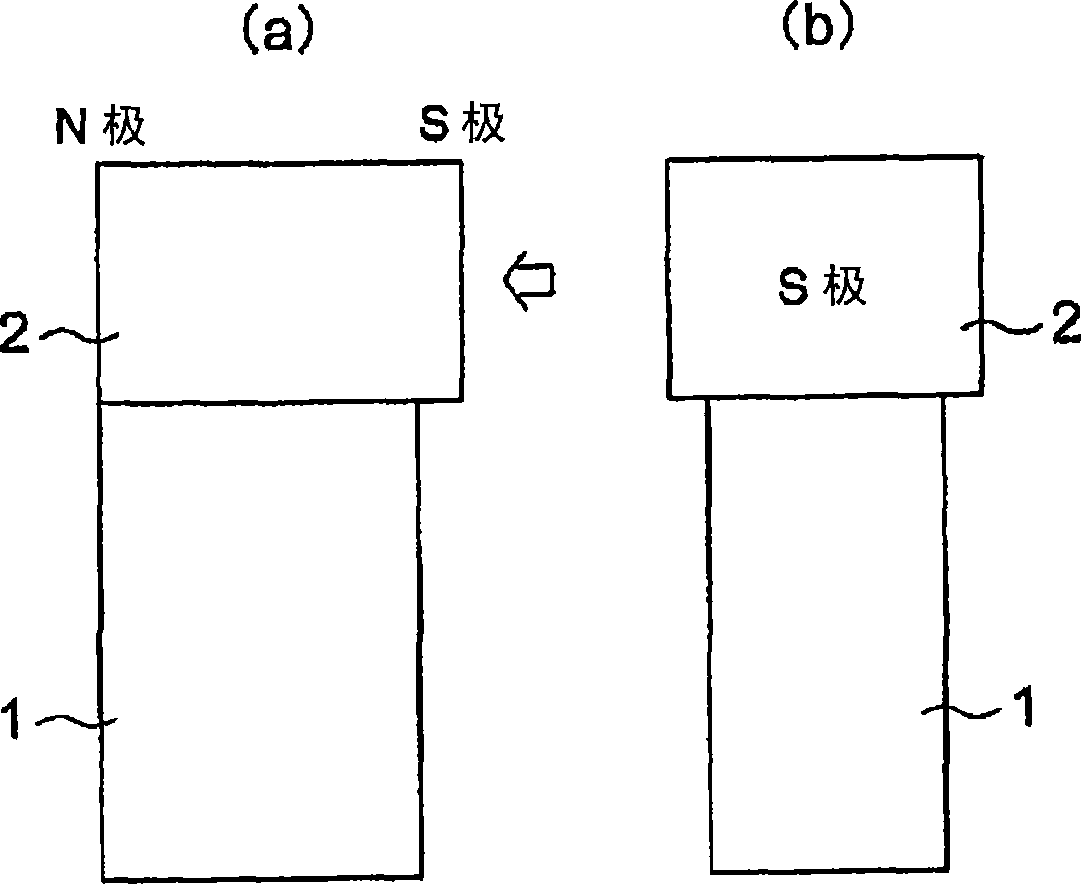

[0062] In this lens module, it is used as a driving body figure 1 The type shown in (a), (b), with respect to the housing 7, the lens holder 6 is installed with the guide pin 8, and the lens holder 6 is installed with a moving member as a moving member made of a material capable of attracting the magnet 4. body 5, and one end face side of the displacement generation direction (longitudinal direction) of the piezoelectric ceramic element 3 made of laminated piezoelectric ceramics is bonded to the magnet 4, and the other end face side is bonded to the magnet 4 as a stationary The casing 7 of the component is made of a material capable of absorbing the magnet 4. The movable body 5 and the magnet 4 as ...

Embodiment 2

[0070] Figure 6 The basic configuration of the lens module according to Example 2 of the present invention is shown, (a) is an external plan view viewed from the upper surface direction, and (b) is a diagram related to a side sectional view in the direction of line BB of (a) .

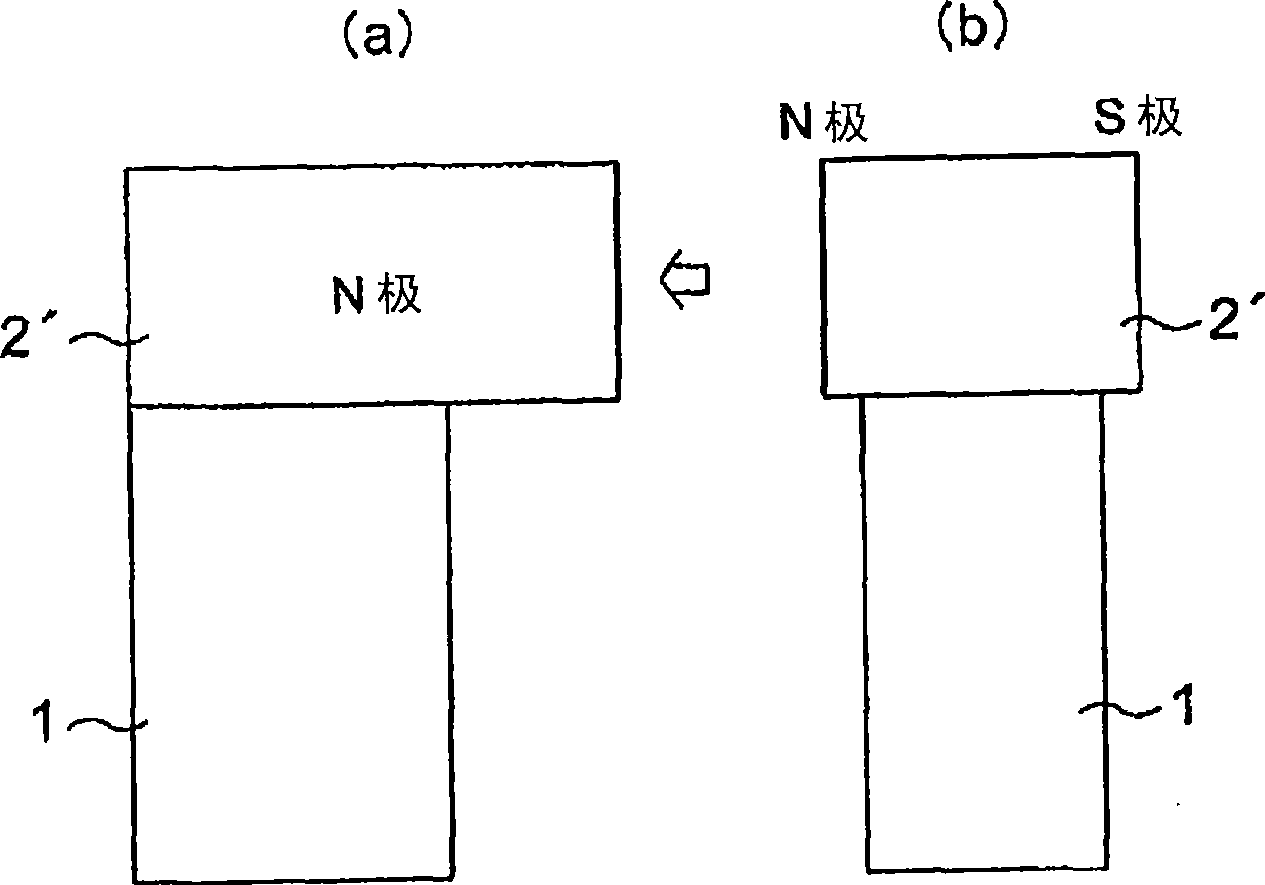

[0071] In this lens module, it is used as a driving body figure 2 The types shown in (a) and (b) are constructed in such a way that the vibration of the housing 7 does not leak out according to the structure of the case of the first embodiment, and are similar to the case of the first embodiment in terms of the basic structure. They are common in that the lens holder 6' is mounted on the housing 7' with the guide pin 8', and the lens holder 6' is equipped with a moving member made of a material capable of attracting to the magnet 4' as a moving member. body 5', and one end face side of the displacement generation direction (longitudinal direction) of the piezoelectric ceramic element 3 made of lami...

Embodiment 3

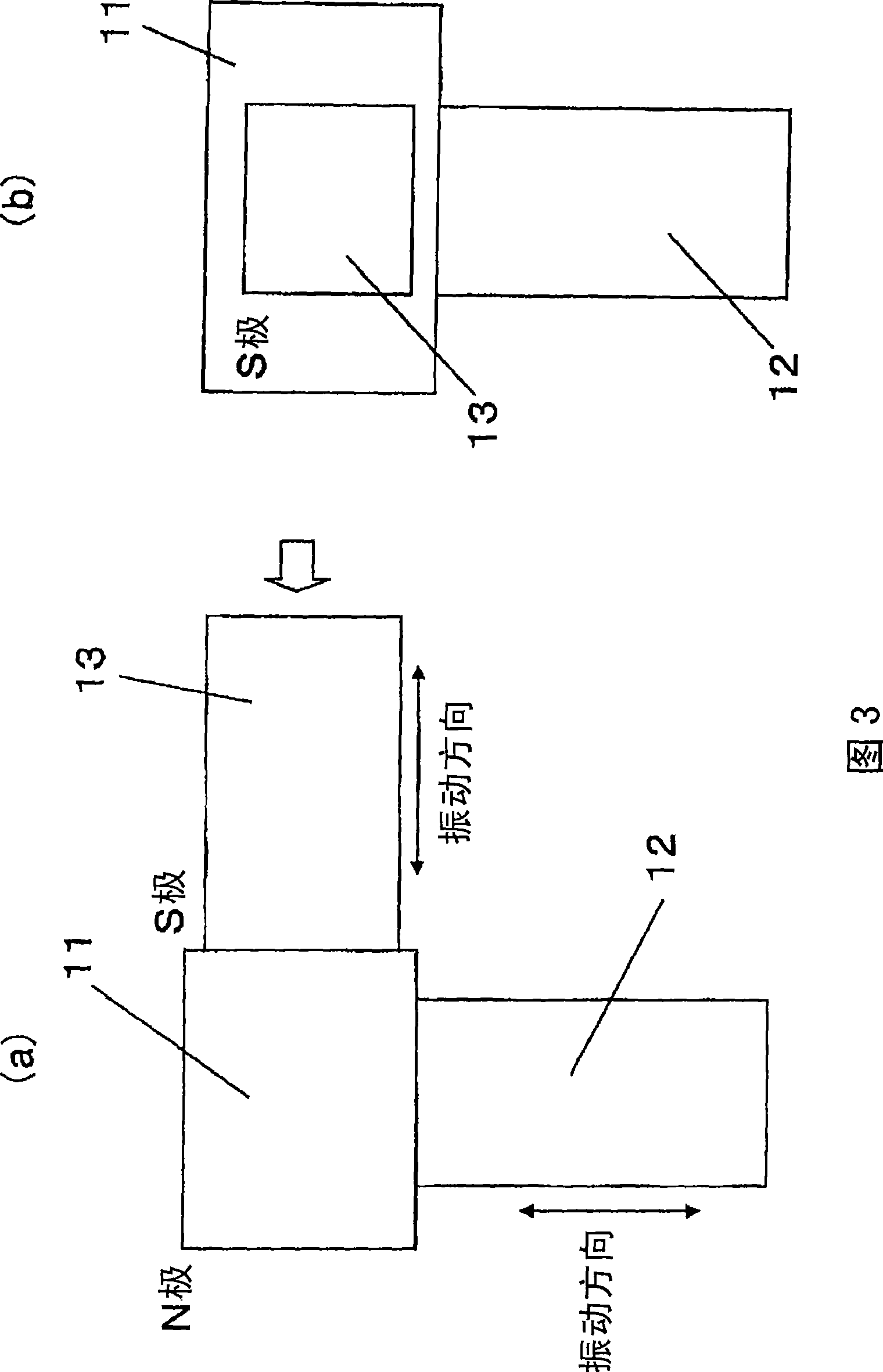

[0094] Fig. 8 shows the basic structure of the lens module according to Embodiment 3 of the present invention, (a) is a diagram related to the external appearance plan view viewed from the upper surface direction, and the same figure (b) is C— Figures related to the side sectional view in the direction of the C line.

[0095] In this lens module 102, it is used as a driving body Figure 6 The type shown in (a), (b) is equipped with the first lens holder 24 of the moving body 18 as a moving member made of a material capable of attracting to the magnet 19, and with respect to the axial direction of the moving body 18 (and light The second lens holder 23 , which is supported so as to be movably axially rotated by the rotation of the same axis), has a structure that is attracted by the magnetic force of the magnet 19 as in the first and second embodiments.

[0096] Here, one end of the piezoelectric ceramic element 20 is bonded to the case 25 as a stationary member, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com