Method for manufacturing molten-metal plated steel band

A hot-dip metal and steel strip technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of reduced coating removal, unstable product quality, and reduced surface quality of steel strips, etc., to achieve Suppresses the occurrence of defects on the surface of the coating, suppresses the generation of spatter, and improves the removal power of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

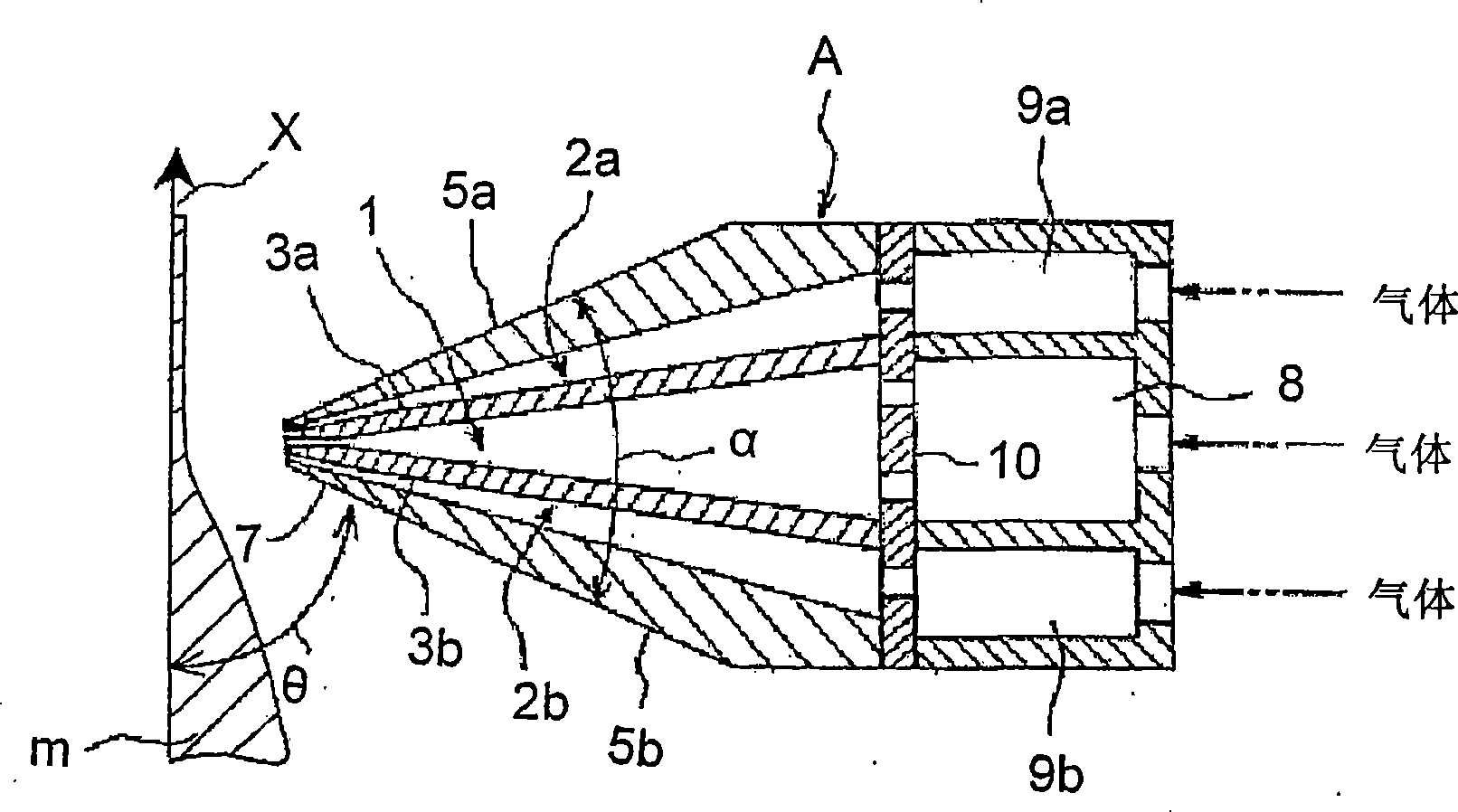

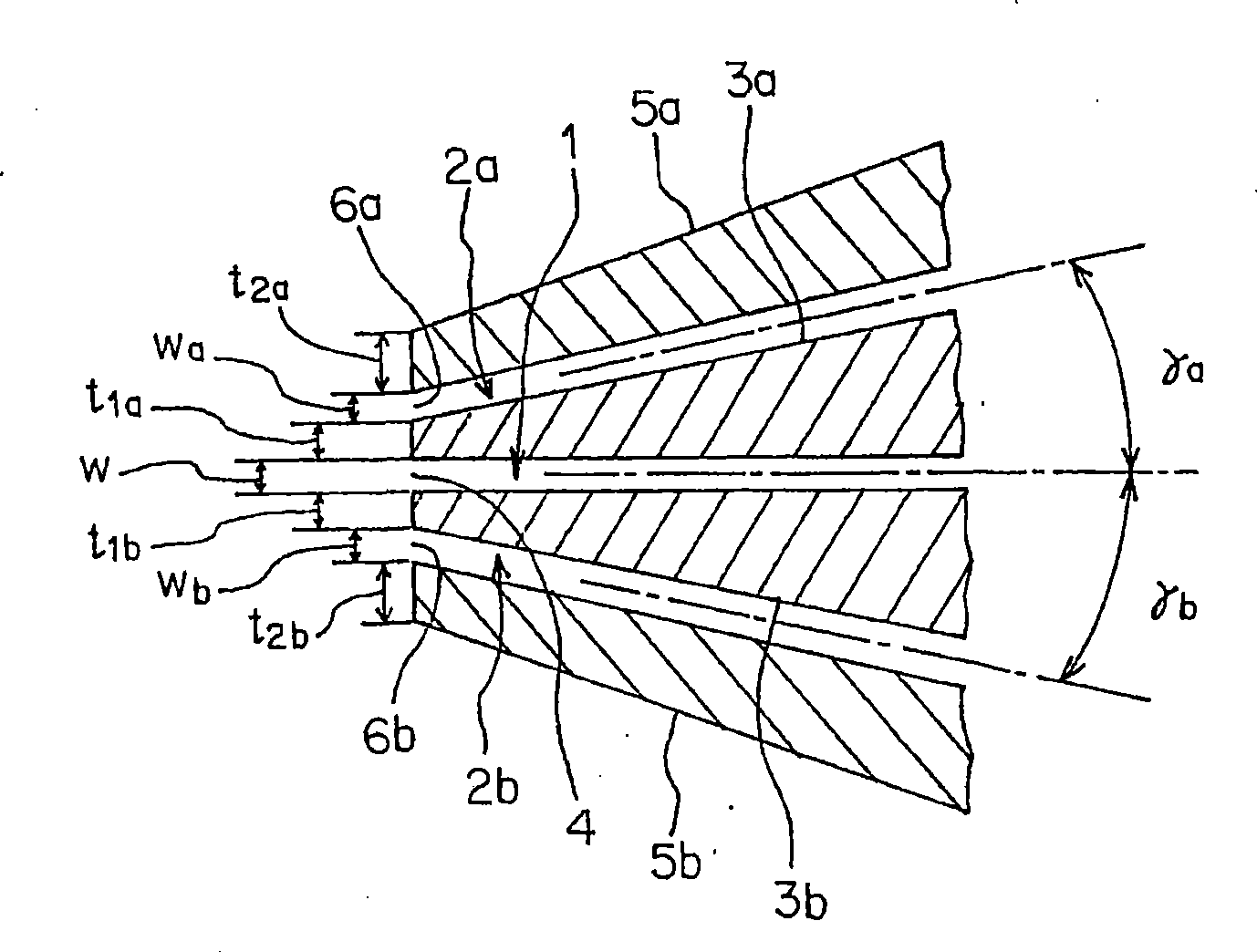

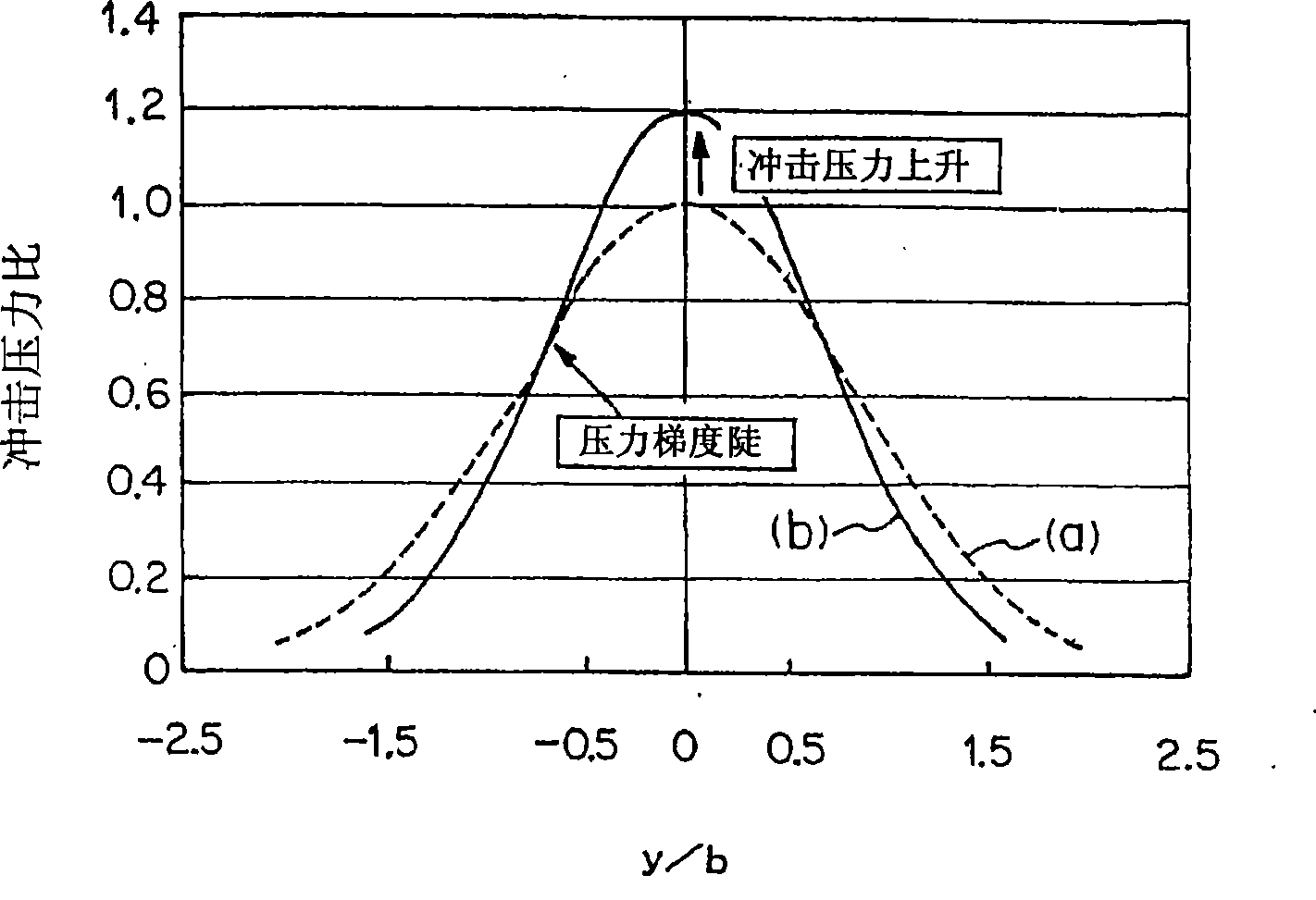

[0095] On the production line of hot-dip galvanized steel strip, various gas wiping nozzles are installed at the position of the gas wiping nozzle above the hot-dip galvanizing bath, and the manufacturing test of the hot-dip galvanized steel strip with a plate thickness of 1.0mm×a plate width of 1200mm is carried out. Manufacturing conditions (same for all tests): Height of gas wiping nozzle from hot-dip galvanizing bath surface: 400mm, hot-dip galvanizing bath temperature: 460°C, main gas injection pressure of gas wiping nozzle: 0.65kgf / cm 2 , The distance between the gas wiping nozzle and the steel strip: 8 mm, the passing speed of the steel strip: 120 mpm, and the amount of coating deposition and the frequency of nozzle clogging in each test were studied (times / hour). The result is as Figure 11 to Figure 15 shown. And, as a gas wiping nozzle, use such as Figure 8 and Figure 10 The upper and lower sides of the main nozzle part are shown in the form of secondary nozzles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com