Liquid heat engine cycle power drive apparatus

A heat engine cycle and heating device technology, applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as low efficiency, consumption of non-renewable resources, etc., and achieve high efficiency, energy saving, various heating methods, and simple heat exchange system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

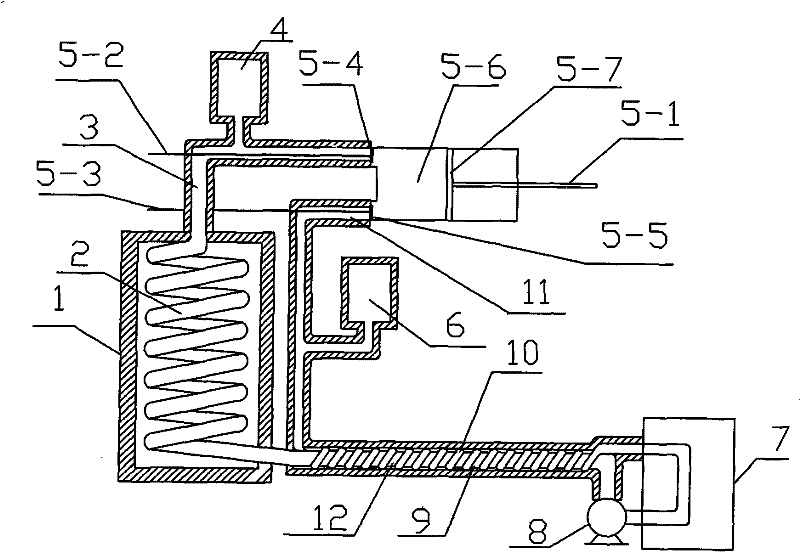

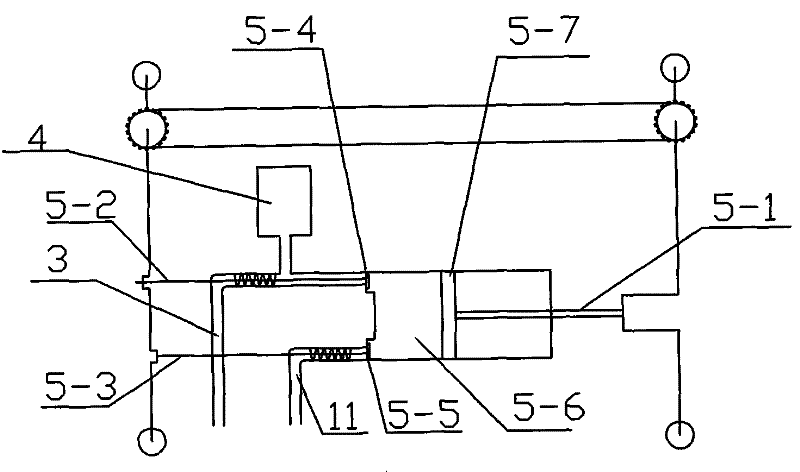

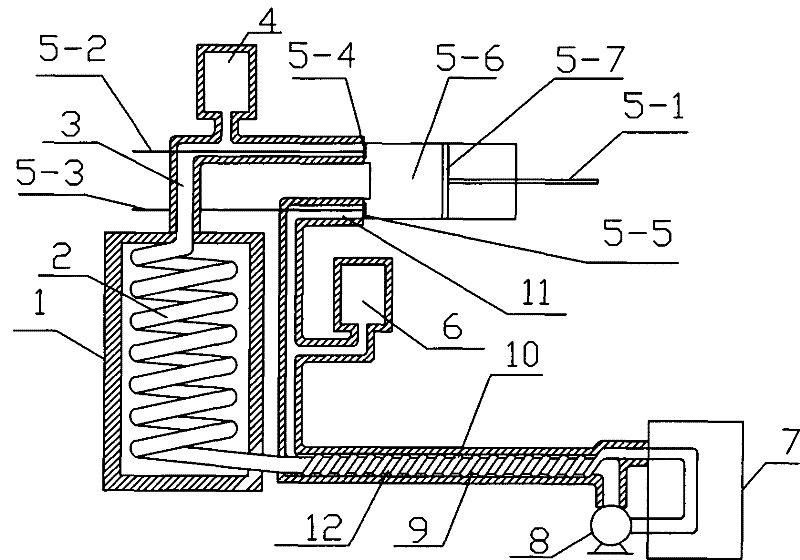

[0009] Such as figure 1 Shown, the technical scheme of the present invention is as follows: it is made of heat supply device 1, heating pipe 2, cooling device 7, cooling pipe 10, heating and stabilizing reserve device 4, cooling and stabilizing reserve device 6, booster pump 8, Piston device 5 forms, and piston device is made of piston connecting shaft 5-1, liquid inlet connecting rod 5-2, liquid outlet connecting rod 5-3, liquid inlet 5-4, liquid outlet 5-5, cylinder 5-6, Composed of piston 5-7, it is characterized in that: the liquid inlet 5-4 of the cylinder is provided with a one-way inlet valve that can only enter liquid but not discharge liquid, and a liquid inlet connecting rod 5-2 is arranged on the one-way inlet valve, and the inlet The amount of liquid is controlled by the liquid inlet connecting rod, and the valve port is connected to the heating pipe 2 installed in the heating device through the liquid inlet pipe 3. The liquid can be heated and expanded in the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com