Fairlead roller arrangement for shipping

A technology for fairlead rollers and ships, which is applied to ships and other directions, can solve the problems of increasing operating costs, easy friction of mooring ropes to the side shell, and reducing the service life of ropes, so as to reduce ship operating costs and benefit ships. Effect of mooring and avoiding friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

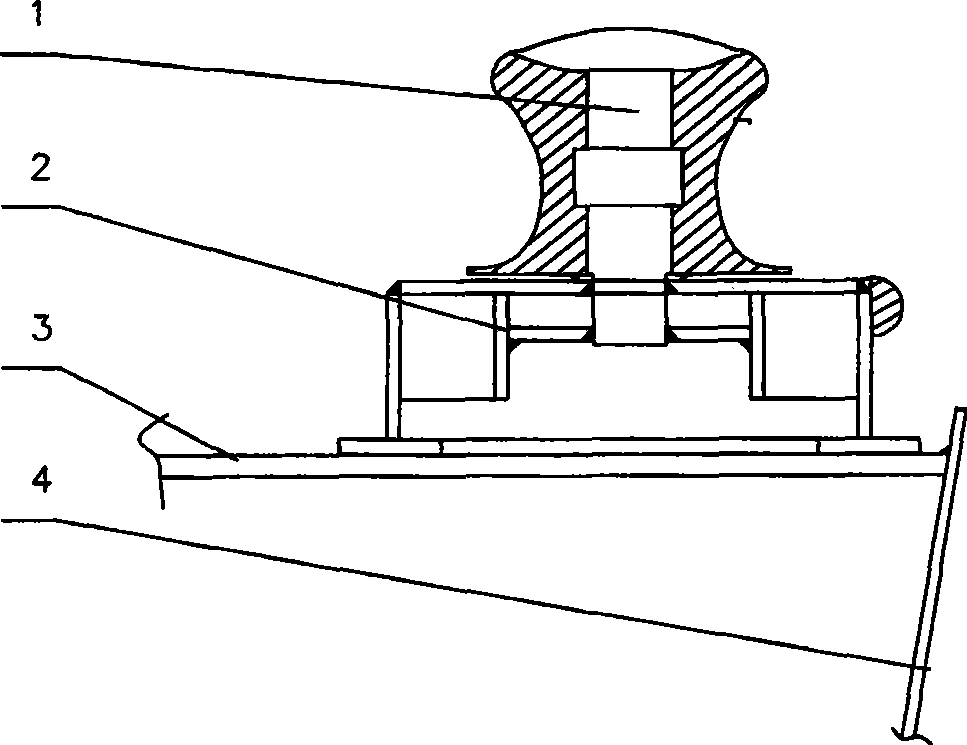

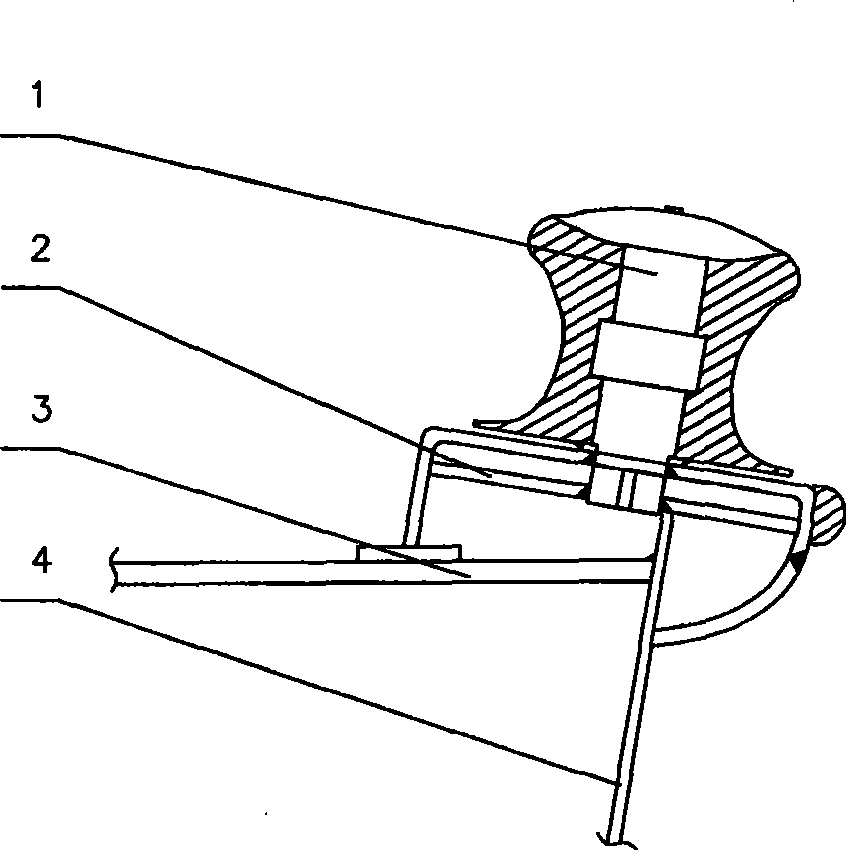

[0009] The present invention comprises a fairlead roller seat 2 and a fairlead roller 1 vertically arranged thereon, the fairlead roller seat 1 is arranged on the forecastle deck 3, and the fairlead roller seat 2 extends outward from the side outer plate 4, The outer part is supported by a semicircular steel set on the side outer plate 4, the fairlead roller seat 2 is inclined downward along the mooring direction of the ship, and the contact part between the fairlead roller seat 2 and the fairlead rope adopts an arc-shaped structure.

[0010] In the present invention, a fairlead roller seat 2 is inclined at a certain angle, so that the fairlead roller 1 and the cable have the same angle when the cable is carried, reducing the stress on the fairlead roller seat 2; Its base of the part of 4 strengthens especially with semicircular steel, makes hawser and can't run into side outer plate 4; The 3rd, stretch out the fairlead roller seat 2 of side outer plate 4 all around and be weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com